Preparation method of graphene supported ferriferrous oxide nanocomposite

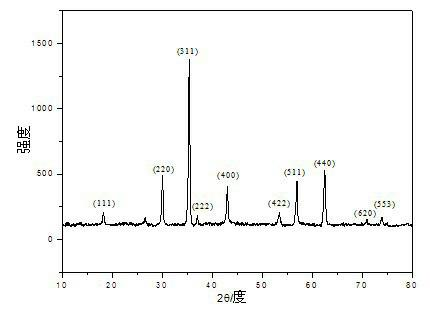

A nano-composite material, ferric oxide technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of difficult calcination and decomposition of iron salts, reduce the difficulty of operation, loss of iron ions, etc. Absorption and other properties, good bonding, good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

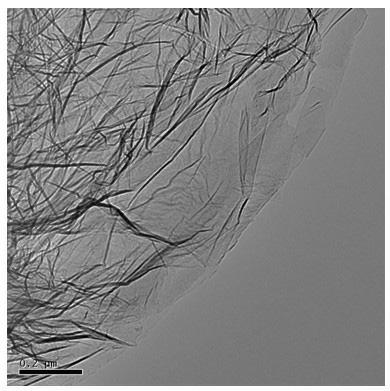

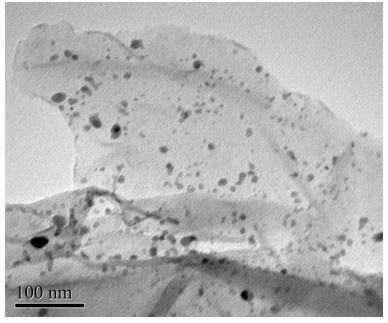

[0024] 0.05g of graphene and 0.05g of Fe(NO) 3 9H 2 O was added to 40 mL of absolute ethanol, stirred magnetically at a temperature of 60°C for 1 h, weighed 0.004 g of sodium dodecylbenzenesulfonate and added to the above solution, and then continued to stir at room temperature. Weigh 0.0149g of NaOH and dissolve it in 30mL of water. After dissolving, pour it into a separatory funnel and drop it into the above solution at a rate of 15 drops / min. After the titration is completed, continue to stir for 1h. Then it was filtered with a Buchner funnel, and the resulting black powder was washed with deionized water until the pH was 7, and dried in an oven at 60°C for 12 hours. Grind the dried powder, spread the obtained powder in a quartz boat, place the quartz boat in the constant temperature zone of the tube furnace, pass argon gas at a flow rate of 200mL / min for 10min to exhaust the air, and then flow it at 7.5°C / min The heating rate was raised to 450°C under the protection of a...

Embodiment 2

[0026] 0.05g of graphene and 0.05g of FeCl 3 ·6H 2O was added to 60 mL of absolute ethanol, and 0.006 g of sodium dodecylbenzenesulfonate was weighed and added to the above solution, stirred magnetically at a temperature of 60° C. for 1 h, and then continued to stir at room temperature. Weigh 0.0222g of NaOH and dissolve it in 30mL of water. After dissolving, pour it into a separatory funnel and drop it into the above solution at a rate of 15 drops / min. After the titration is completed, continue to stir for 1h. Then it was filtered with a Buchner funnel, and the obtained black powder was washed with deionized water until the pH was 7, and dried in an oven at a temperature of 60°C for 12 hours. Grind the dried powder, spread the obtained powder in a quartz boat, place the quartz boat in the constant temperature zone of the tube furnace, pass argon gas at a flow rate of 200mL / min for 10min to exhaust the air, and then flow it at 7.5°C / min The heating rate was raised to 450°C u...

Embodiment 3

[0028] 0.02g of graphene and 0.01g of Fe(NO) 3 9H 2 O was added to 40 mL of absolute ethanol, stirred magnetically at a temperature of 60°C for 1 h, weighed 0.004 g of sodium dodecylbenzenesulfonate and added to the above solution, and then continued to stir at room temperature. Weigh 0.003g of NaOH and dissolve it in 10mL of water. After dissolving, pour it into a separatory funnel and drop it into the above solution at a rate of 15 drops / min. After the titration is completed, continue to stir for 0.5h. Then it was filtered with a Buchner funnel, and the resulting black powder was washed with deionized water until the pH was 7, and dried in an oven at 80°C for 12 hours. Grind the dried powder, spread the obtained powder in a quartz boat, place the quartz boat in the constant temperature zone of the tube furnace, pass argon gas at a flow rate of 150mL / min for 15min to exhaust the air, and then flow it at 7.5°C / min The heating rate was raised to 450°C under the protection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com