Efficient and energy-saving xylose producing process

A production process, high-efficiency and energy-saving technology, applied in sugar production, sugar production, food science, etc., can solve the problems of short resin regeneration cycle, large amount of regeneration wastewater, and large evaporation consumption, so as to reduce steam consumption and reduce Pollution load, the effect of extending the exchange period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is the best embodiment of the present invention.

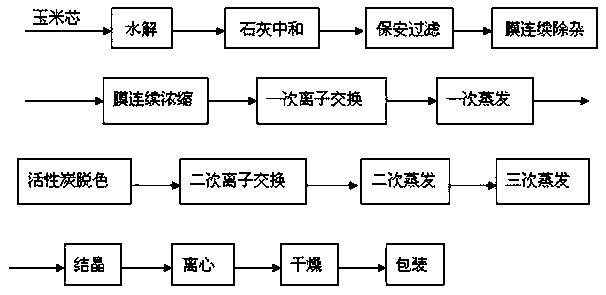

[0034] A high-efficiency and energy-saving xylose production process, such as figure 1 As shown, it includes the following steps:

[0035] A. Corn cob hydrolysis: mix corn cob with water at a weight ratio of 1:60, add a weak acid catalyst with a weight percentage of corn cob of 1, cook at 170°C for 80 minutes for cracking, and dissolve xylan in the corn cob;

[0036] B. Lime neutralization: add lime to the hydrolyzate to neutralize the acid catalyst in the hydrolyzate, adjust the pH to 2, and then filter through waste carbon;

[0037] C. Security filtration: filter the filtrate from the previous step through a 5 μm bag filter to remove particles and suspended solids;

[0038] D. Membrane continuous impurity removal: use ultrafiltration membrane with a molecular weight of 1000Da, adopt continuous impurity removal method to intercept impurities such as protein, colloid, pigment, calcium and magnesium in...

Embodiment 2

[0051] A high-efficiency and energy-saving xylose production process, such as figure 1 As shown, it includes the following steps:

[0052] A. Corn cob hydrolysis: mix corn cob with water at a weight ratio of 1:50, add a weak acid catalyst with a weight percentage of corn cob of 0.2, cook at 155° C. for 120 min for cracking, and dissolve xylan in the corn cob;

[0053] B. Lime neutralization: add lime to the hydrolyzate to neutralize the acid catalyst in the hydrolyzate, adjust the pH to 1, and then filter through waste carbon;

[0054] C. Security filtration: filter the filtrate from the previous step through a 5 μm bag filter to remove particles and suspended solids;

[0055] D. Membrane continuous impurity removal: use an ultrafiltration membrane with a molecular weight of 1500Da to intercept impurities such as protein, colloid, pigment, calcium and magnesium inorganic salts, etc., and the light transmittance of the hydrolyzed solution is over 80%;

[0056] E. Membrane con...

Embodiment 3

[0068] A high-efficiency and energy-saving xylose production process, such as figure 1 As shown, it includes the following steps:

[0069] A. Corn cob hydrolysis: mix corn cob with water at a weight ratio of 1:70, add a weak acid catalyst with a weight percentage of corn cob of 1.5, cook at 180° C. for 30 minutes for cracking, and dissolve xylan in the corn cob;

[0070] B. Lime neutralization: add lime to the hydrolyzate to neutralize the acid catalyst in the hydrolyzate, adjust the pH to 3, and then filter through waste carbon;

[0071] C. Security filtration: filter the filtrate from the previous step through a 5 μm bag filter to remove particles and suspended solids;

[0072] D. Membrane continuous impurity removal: the ultrafiltration membrane with a molecular weight of 2000Da is used to intercept impurities such as proteins, colloids, pigments, calcium and magnesium inorganic salts, etc., and the light transmittance of the hydrolyzate reaches more than 80%;

[0073] E....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com