Vacuum coating preparation method of aviation organic glass and preparation thereof

A technology of vacuum coating and plexiglass, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of the adhesion between the anti-reflection coating and the spectacle lens substrate needs to be further improved, and achieve high adhesion , High light transmittance, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

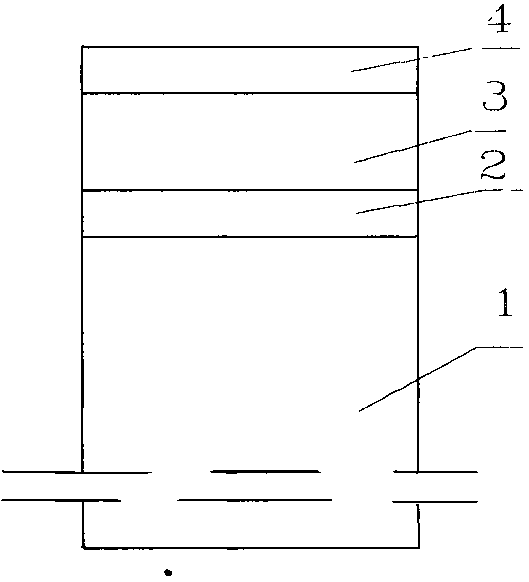

[0020] 1. Transparent aviation plexiglass window plate base material (polymethyl methacrylate) coating workpiece (7), its specification is: diameter 211mm x thickness 5mm.

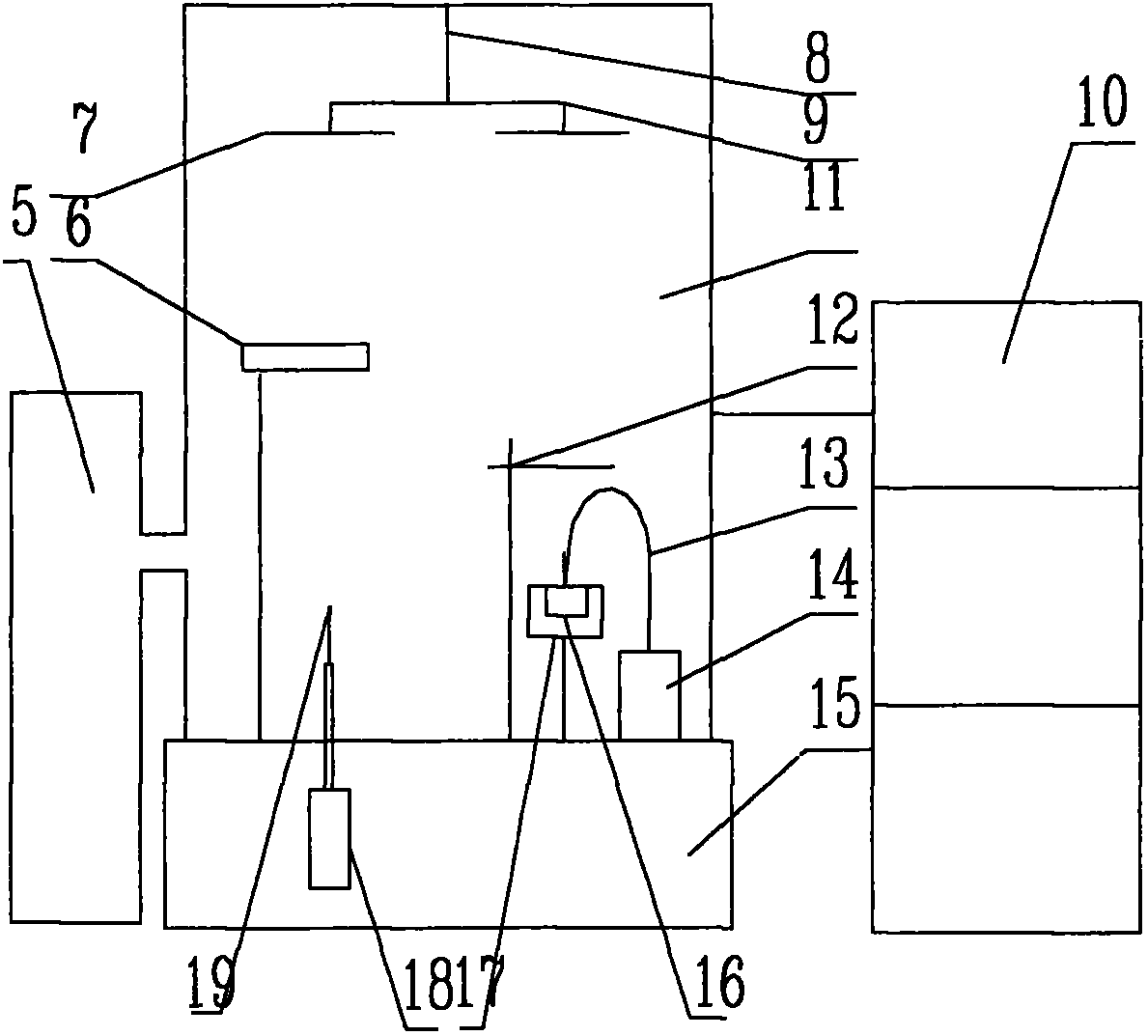

[0021] 2. A vertical vacuum coating device is used to continuously complete the preparation of three layers of film on the substrate and workpiece. The structure of the vacuum coating device is as follows: the vertical single-door vacuum chamber box (11) is connected with the vacuum pump group (5), the electron gun electron beam evaporation system (14) is installed on the bottom plate of the box body, and the film material with indexing is used. The four-hole crucible (17), the metal oxide film material (16) is placed in the crucible hole, the indexable baffle (12) is located 200 mm above the crucible, an ion bombardment holder (6) is located in the middle of the vacuum chamber, and the vacuum chamber top plate A vertical shaft system (8) is installed on the lower surface to drive a turntable, on which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com