Flue gas desulfurization tower

A desulfurization tower and flue gas technology, which is applied in the directions of air quality improvement, combined device, dispersed particle separation, etc., can solve the problems of increased pressure drop in the operation of the desulfurization system, difficult to eliminate aerosols, and inability to remove them, so as to reduce investment costs. and operating costs, reducing the number of demister stages, and reducing the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

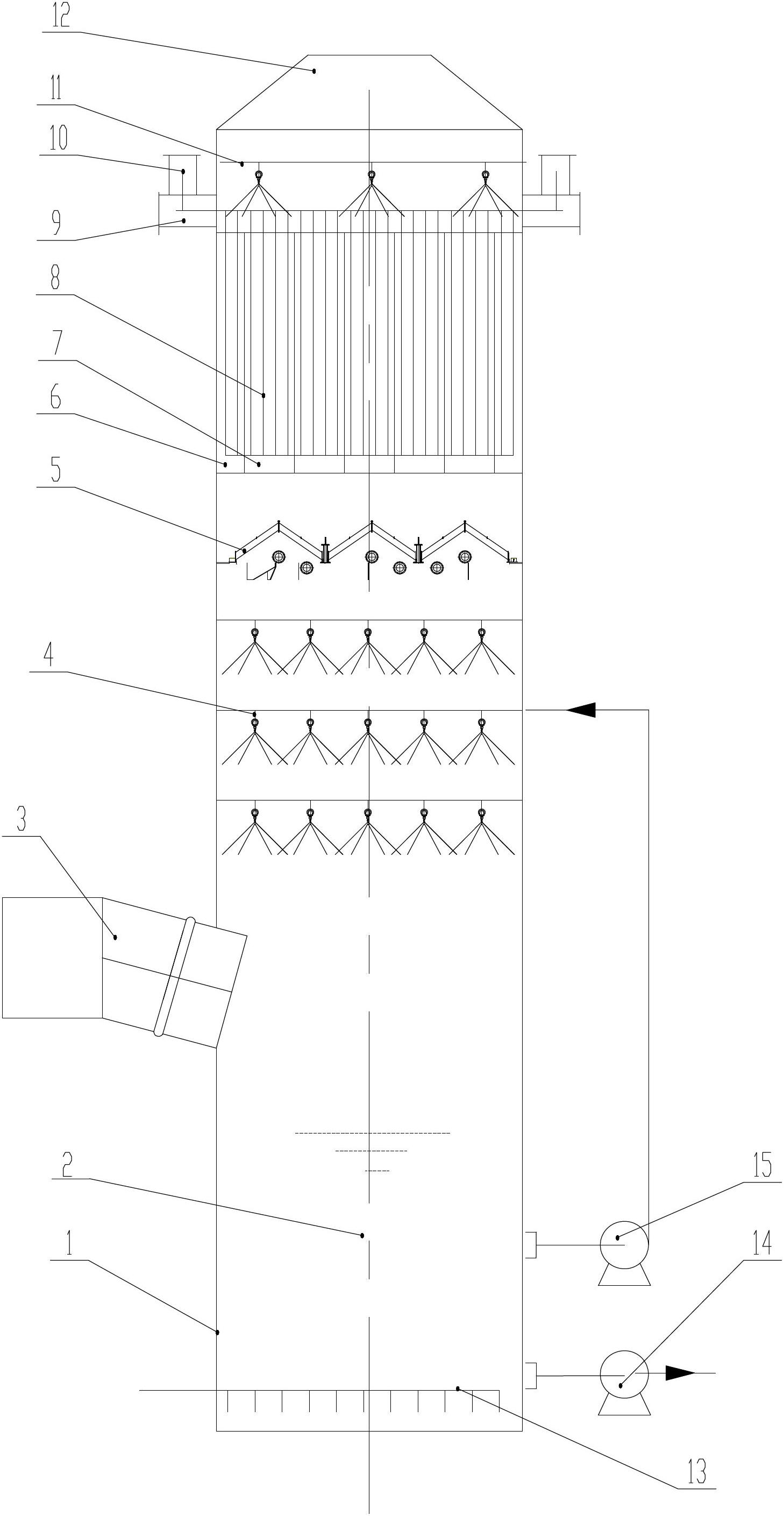

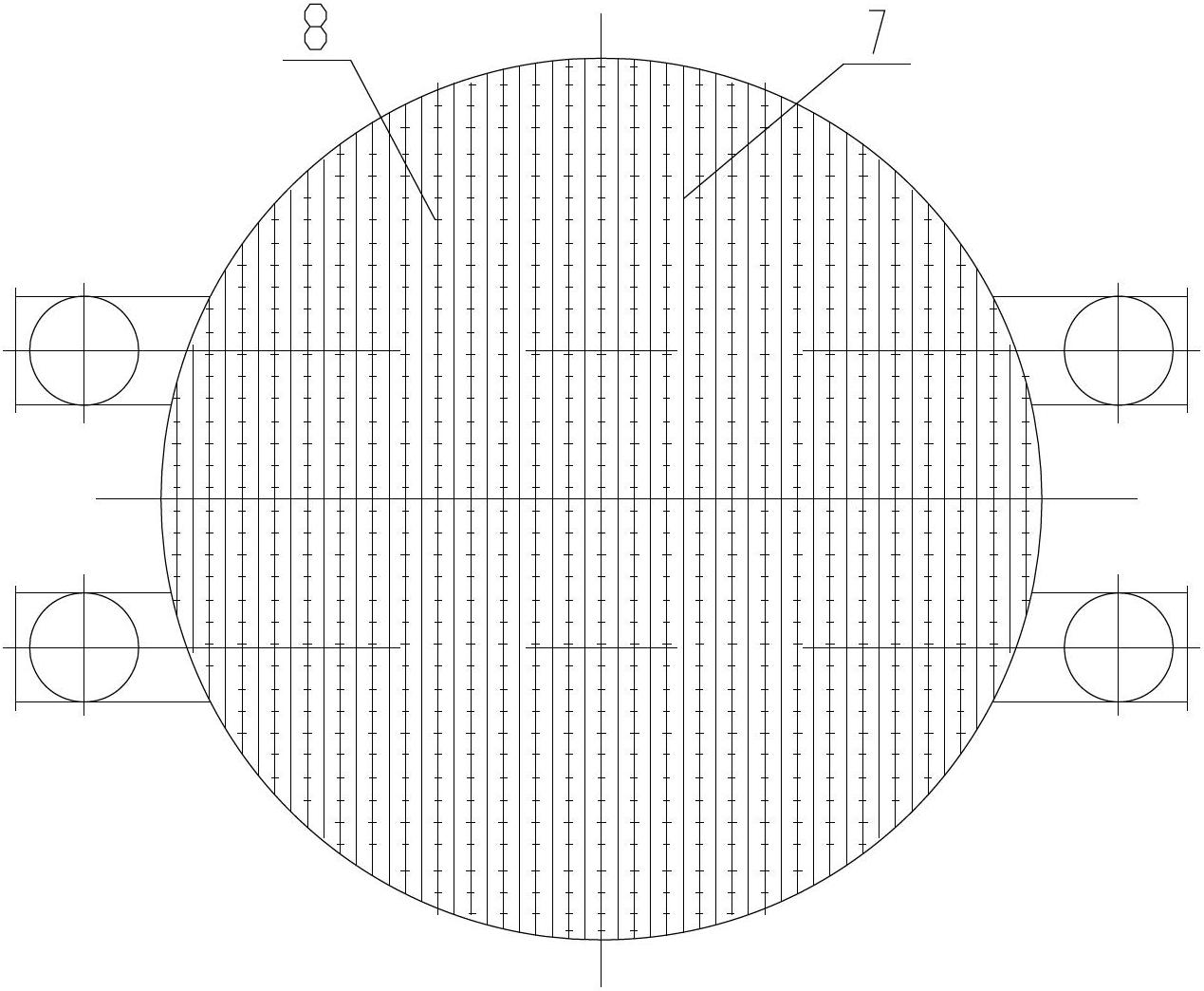

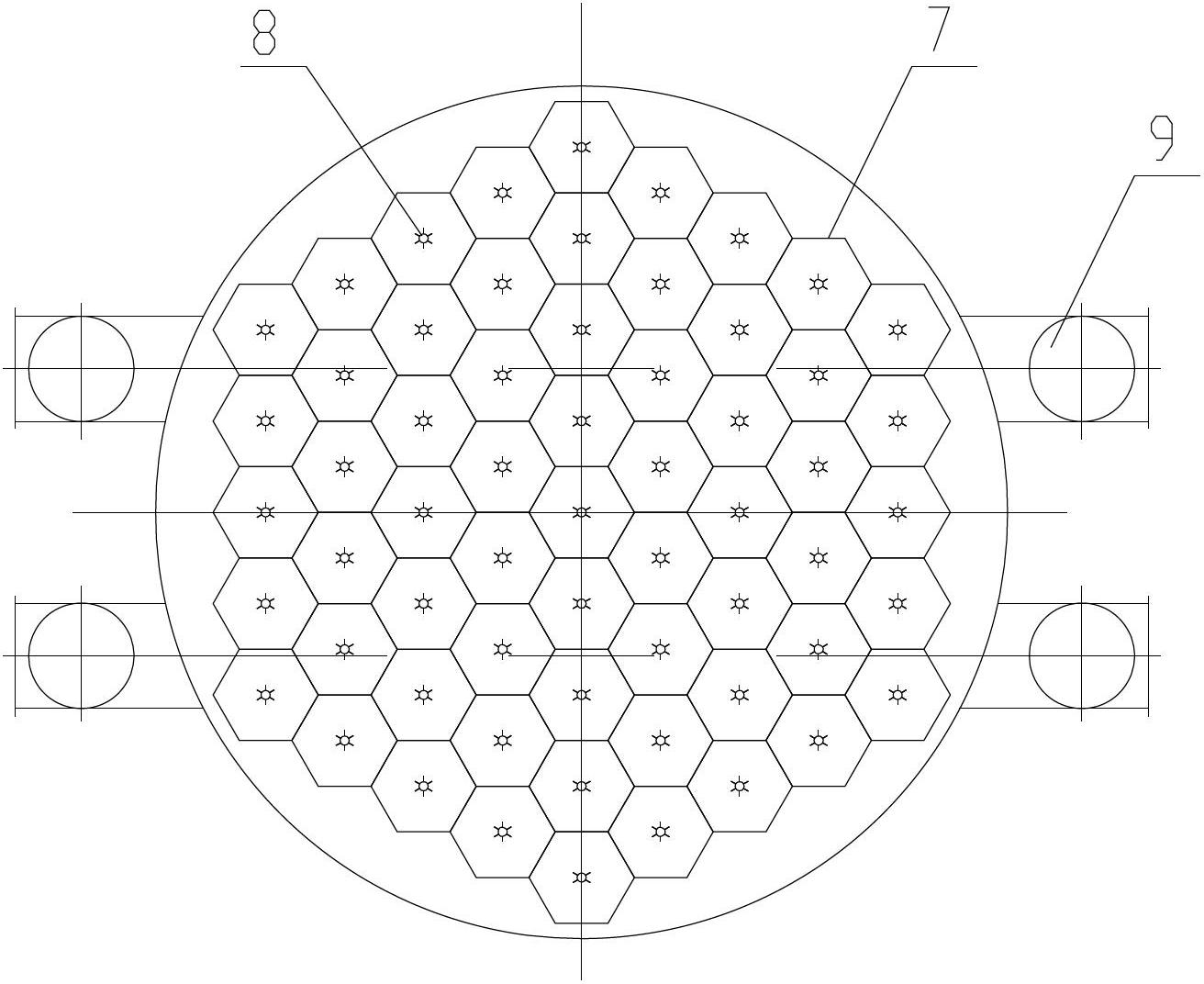

[0016] refer to figure 1 It is an embodiment of a flue gas desulfurization tower of the present invention. A flue gas desulfurization tower includes a tower body 1, and the tower body 1 is sequentially provided with a circulating slurry pool 2, a spray layer 4, a mechanical desulfurization Fogger 5, wet electrostatic precipitator 6, flue gas inlet 3 is set on tower body 1 below spray layer 4, flue gas outlet 12 is set on the top of tower body 1, and said spray layer 4 is provided with three or four stages stage, the circulating slurry pool 2 is connected with a slurry circulating pump 15, and the slurry circulating pump 15 is connected with the spray layer 4, and the wet electrostatic precipitator 6 includes a discharge electrode 8, a dust collecting electrode 7, and a cleaning dust collecting electrode 7 The water film flushing device 11 for dust, the electric control device 10 for powering the discharge electrode 8, the discharge electrode 8 is located above the dust collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com