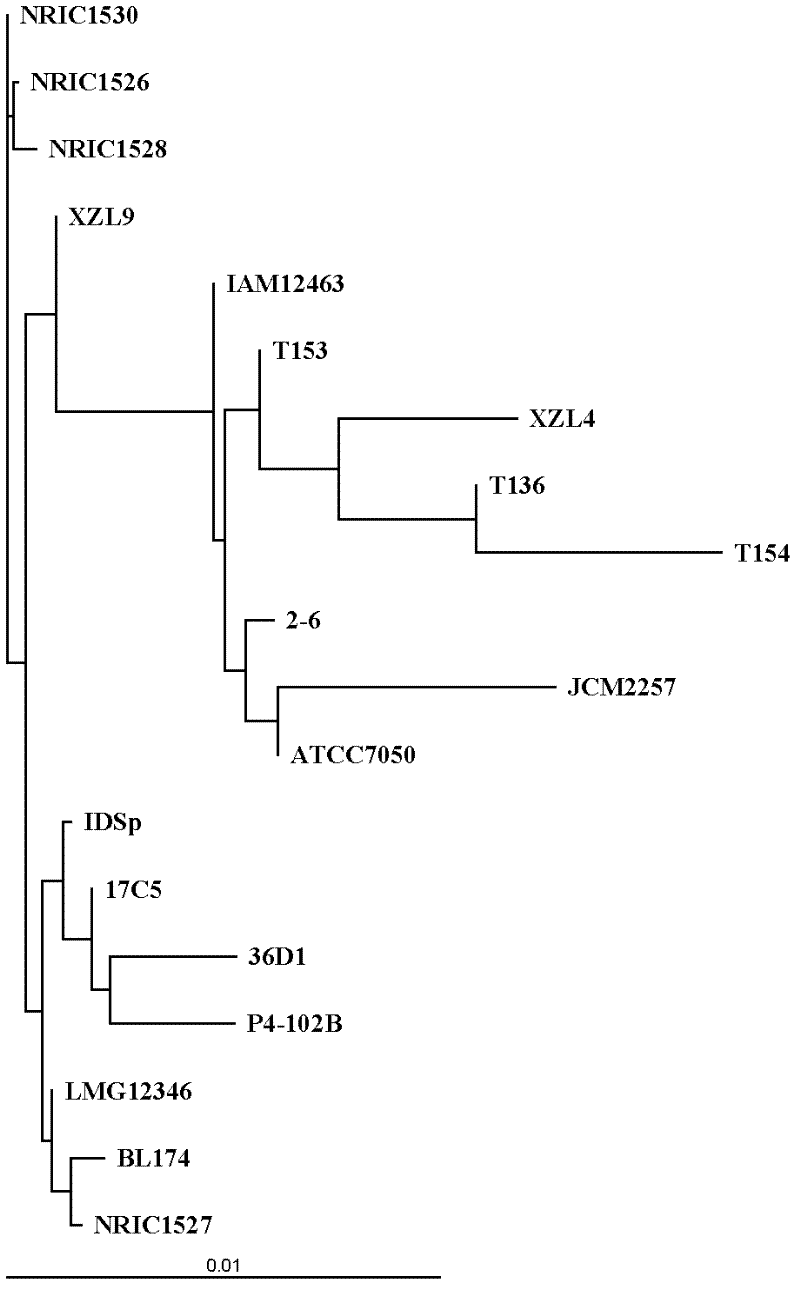

Bacillus coagulans used to preparing L-lactic acid and application method thereof

A technology of Bacillus coagulans and lactic acid, applied in the field of lactic acid preparation, can solve the problems of unutilization, limited application, waste, etc., and achieve the effect of cost saving, low cost and strong ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

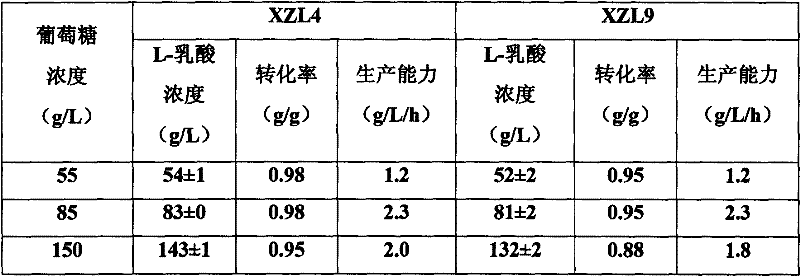

[0074] Batch Fermentation of L-Lactic Acid Using Bacillus coagulans (B. coagulans) XZL4 DSM No.23183 and XZL9 DSM No.23184 Using Glucose as Carbon Source in Erlenmeyer Flasks

[0075] The composition of each culture medium used in the present embodiment is as follows:

[0076] Each liter of slant medium contains: xylose 30g, yeast powder 10g, CaCO 3 10g, agar powder 15g, and the balance is water. The pH of the slant medium is 6.5. It is sterilized at 115° C. for 20 minutes.

[0077] Each liter of seed medium contains: glucose 50g, yeast powder 10g, CaCO 3 20g, the balance is water. The pH of the seed medium was 6.5. It was sterilized at 115° C. for 20 minutes.

[0078] Each liter of fermentation medium contains: glucose 55-150g, yeast powder 10g, CaCO 3 60g, and the balance is water; the pH of the fermentation medium is 5.5-7. Sterilize at 115°C for 20 minutes.

[0079] The method for producing L-lactic acid by fermentation described in this embodiment comprises the f...

Embodiment 2

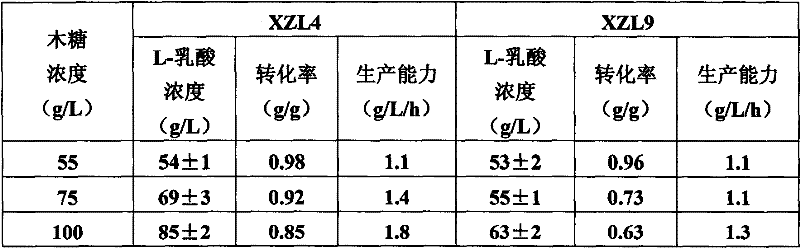

[0088] Using Bacillus coagulans (B. coagulans) XZL4 DSM No.23183 and XZL9 DSM No.23184 to produce L-lactic acid in Erlenmeyer flasks by batch fermentation with xylose as carbon source:

[0089] The composition of each culture medium used in the present embodiment is as follows:

[0090] The slant medium and seed medium are the same as in Example 1.

[0091] Each liter of fermentation medium contains: xylose 55-100g, yeast powder 10g, CaCO 3 60g, and the balance is water; the pH of the fermentation medium is 5.5-7. Sterilize at 115°C for 20 minutes.

[0092] The method for producing L-lactic acid by fermentation comprises the following steps:

[0093] (1) inclined plane culture: with embodiment 1;

[0094] (2) seed culture: with embodiment 1;

[0095] (3) fermentation culture: with embodiment 1.

[0096] When the contents of xylose and L-lactic acid remain stable, the fermentation ends. According to the detection and calculation method described in the above specific embo...

Embodiment 3

[0100] Bacillus coagulans (B. coagulans) XZL4 DSM No.23183 and XZL9 DSM No.23184 were used to produce L-lactic acid by batch fermentation in Erlenmeyer flasks with xylitol production by-products as carbon source:

[0101] The slant medium and seed medium are the same as in Example 1.

[0102] Each liter of fermentation medium contains: xylitol production by-product 75 ~ 150g, yeast powder 10g, CaCO 3 60g, and the balance is water; the pH of the fermentation medium is 5.5-7. Sterilize at 115°C for 20 minutes.

[0103] The method for producing L-lactic acid by fermentation comprises the following steps:

[0104] (1) inclined plane culture: with embodiment 1;

[0105] (2) seed culture: with embodiment 1;

[0106] (3) Fermentation culture: 10 ml of the seed culture solution prepared in step (2) was inserted into a 300 ml Erlenmeyer flask equipped with 90 ml of fermentation medium, and cultured at 50° C. for 48 hours to finish the fermentation.

[0107] After the fermentation,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com