Tubular nanofiltration membrane with multi-layer structure and preparation method thereof

A multi-layer structure and nanofiltration membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of poor mechanical properties of tubular nanofiltration membranes without specifying the reinforcement composition and reinforcement method , Interlayer connections are not firm, etc., to achieve the effect of improving pollution resistance, structural stability, and hindering adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

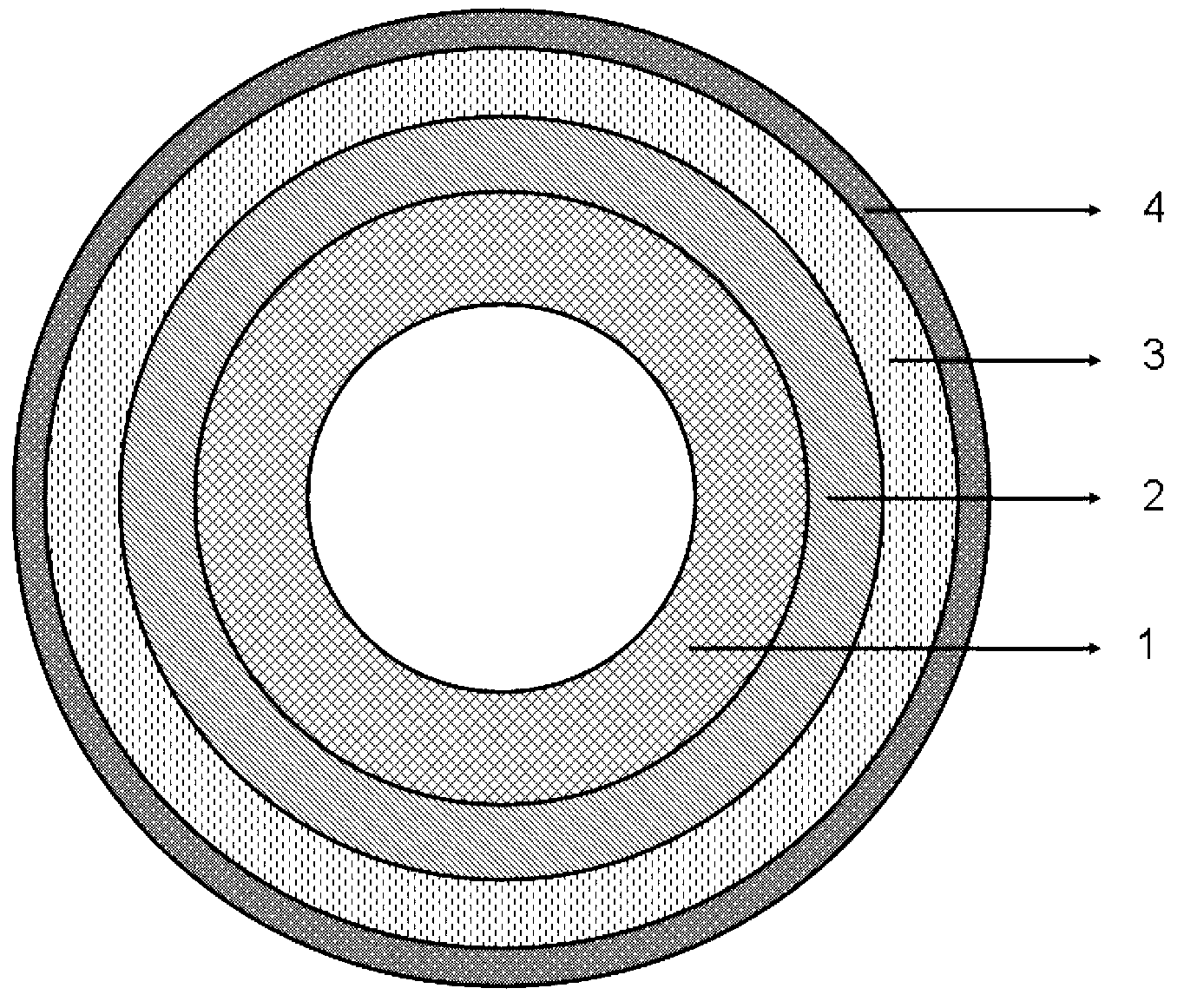

[0070] The preparation method of the multi-layer structure tubular nanofiltration membrane comprises the following steps:

[0071] 1. Put the polymer fiber braided tube at 0.5~5.0mol·L -1 Soak in sodium hydroxide or potassium hydroxide solution for 5~20 minutes for alkali treatment, take out and wash with water, and then pass 0.1~5mol·L -1 The sulfuric acid or hydrochloric acid solution was soaked for 5 to 20 minutes for acid treatment, and washed with water to obtain a carboxyl-containing polymer fiber braided tube;

[0072] 2. Immerse the carboxyl-containing polymer fiber braided tube in the dipping solution for 1 to 10 seconds, take out and heat treatment at 40 to 60 ° C for 10 to 40 seconds, and then immerse it in water at 20 to 40 ° C for 5 to 30 seconds. Then heat treatment at 60-80° C. for 0.5-4 hours, so that the inorganic matter is filled into the carboxyl-containing polymer fiber braided tube, and the microfiltration support tube 1 is obtained.

[0073] 3. The m...

Embodiment 1

[0095] 1. Preparation of Microfiltration Support Tube 1

[0096] 1.1 Carboxylation treatment of polymer fiber braided tube: The polyethylene terephthalate polymer fiber braided tube with an outer diameter of 1.0 mm and a wall thickness of 0.3 mm is placed in a 0.5 mol·L -1 Soak in the sodium hydroxide solution for 20 minutes for alkali treatment, take out and wash with water, and then add 0.1 mol L -1 Soak in the sulfuric acid solution for 20 minutes for acid treatment, take out the water for cleaning, and air dry to obtain a carboxyl-containing polymer fiber braided tube;

[0097] 1.2 Inorganic filling of polymer fiber braided tube: Dissolve 5g of methyl orthosilicate in 95g of ethanol to prepare an impregnation solution, and then immerse the carboxyl group-containing polymer fiber braided tube in the impregnation solution for 10 seconds and take it out. Heat treatment at 40 ° C for 40 seconds, then immerse in water at 20 ° C for 30 seconds and take out, then heat treatment ...

Embodiment 2

[0114] 1. Preparation of Microfiltration Support Tube 1

[0115] 1.1 Carboxylation treatment of polymer fiber braided tube: The poly(paraphenylene terephthalamide) polymer fiber braided tube with an outer diameter of 2.0 mm and a wall thickness of 0.6 mm is placed in a 5.0 mol·L -1 Soak in the sodium hydroxide solution for 5 minutes for alkali treatment, take out and wash with water, and then add in 5.0mol·L -1 Soak in the hydrochloric acid solution for 5 minutes for acid treatment, take it out for washing with water, and air dry to obtain a carboxyl-containing polymer fiber braided tube;

[0116] 1.2 Inorganic filling of polymer fiber braided tube: Dissolve 50 g of methyl orthosilicate in 50 g of ethanol to prepare an impregnation solution, and then immerse the carboxyl group-containing polymer fiber braided tube in the impregnating solution for 1 second and then take it out. Heat treatment at 60 ° C for 10 seconds, then immersed in water at 40 ° C for 5 seconds and then tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com