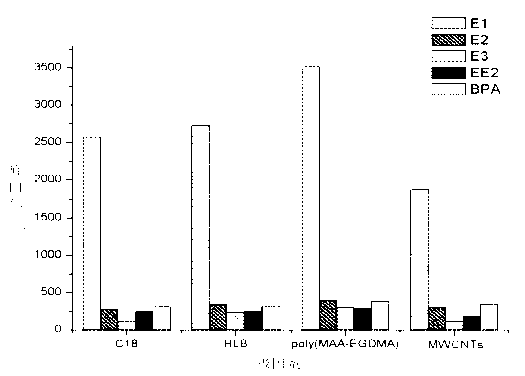

Method for preparing extraction probe by means of micro-solid phase extraction based on polymer (methacrylic acid-ethyl glycol dimethacrylate)

A technology of ethylene glycol dimethacrylate and methacrylic acid, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve problems such as matrix interference, achieve low detection limit and good extraction effect , good effect of testing repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

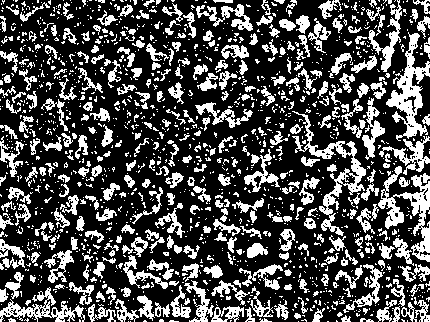

[0025] Take 1mmol of methacrylic acid, 3mmol of ethylene glycol dimethacrylate, 2mL of acetonitrile and 0.011g of azobisisobutyronitrile in a 5mL centrifuge tube and mix well. 2 Remove oxygen for 15min, seal the centrifuge tube and place it in an oven to heat at 60°C for 15h, take out the product and grind it, pass through a 100-mesh sieve to obtain poly(MAA-EGDMA) powder ( figure 1 for scanning electron microscopy).

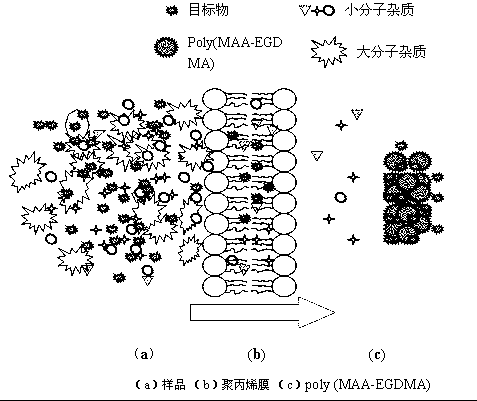

[0026] Cut the polypropylene film into 2.0cm×1.5cm, fold the long side in half, heat seal both sides with a small plastic sealing machine to ensure that the edges are sealed neatly, add 20mg poly(MAA-EGDMA) powder to the opening of the film bag through funnel drainage, and heat Seal the opening and cut off the protruding part of the edge, immerse the extraction probe in pure water and methanol successively, clean it by ultrasonic for 5 minutes each at a power of 500w, and dry it for later use.

Embodiment 2

[0028] Take 2mmol of methacrylic acid, 3mmol of ethylene glycol dimethacrylate, 1mL of ethyl acetate and 0.011g of azobisisobutyronitrile in a 5mL centrifuge tube and mix well. 2 Remove oxygen for 15 minutes, seal the centrifuge tube and place it in an oven to heat at 60°C for 15 hours, take out the product, grind it, and pass through a 100-mesh sieve to obtain poly(MAA-EGDMA) powder.

[0029] Cut the polypropylene film into 2.0cm×1.5cm, fold the long side in half, heat seal both sides with a small plastic sealing machine to ensure that the edges are sealed neatly, add 20mg poly(MAA-EGDMA) powder to the opening of the film bag through funnel drainage, and heat Seal the opening and cut off the protruding part of the edge, immerse the extraction probe in pure water and methanol successively, clean it by ultrasonic for 5 minutes each at a power of 500w, and dry it for later use.

Embodiment 3

[0031] Take 3mmol of methacrylic acid, 4mmol of ethylene glycol dimethacrylate, 3mL of toluene and 0.011g of azobisisobutyronitrile in a 5mL centrifuge tube and mix well. 2Remove oxygen for 15 minutes, seal the centrifuge tube and place it in an oven to heat at 60°C for 15 hours, take out the product, grind it, and pass through a 100-mesh sieve to obtain poly(MAA-EGDMA) powder.

[0032] Cut the polypropylene film into 2.0cm×1.5cm, fold the long side in half, heat seal both sides with a small plastic sealing machine to ensure that the edges are sealed neatly, add 20mg poly(MAA-EGDMA) powder to the opening of the film bag through funnel drainage, and heat Seal the opening and cut off the protruding part of the edge, immerse the extraction probe in pure water and methanol successively, clean it by ultrasonic for 5 minutes each at a power of 500w, and dry it for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com