Method for preparing cefotaxime acid

A technology of cefotaxime acid and carboxylic acid, which is applied in the field of preparation of cefotaxime acid, can solve the problems of low content of cefotaxime acid, achieve the effect of shortening the reaction time, increasing the content and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

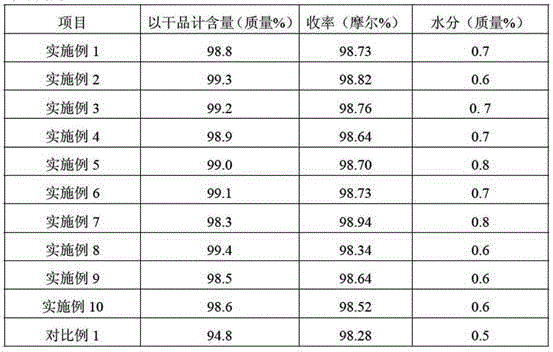

Examples

Embodiment 1

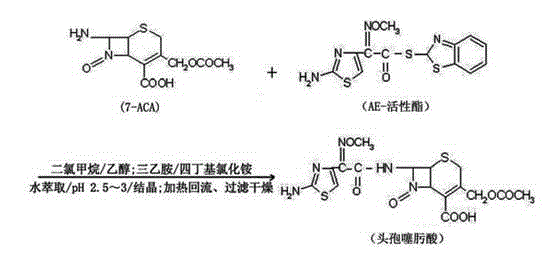

[0023] Mix 20.0 g of 7-ACA and 26.0 g of AE-active ester in 130 ml of dichloromethane and 20 ml of isopropanol, add 1 g of tetrabutylammonium bromide and 14 ml of triethylamine, and react with water for 1 h. Extract the organic phase twice, adjust the pH to 2.5-3.0 with hydrochloric acid, crystallize at room temperature for 1 h, and filter with suction to obtain 37 g of cefotaxime acid wet powder. Add 740 ml of acetone, heat, and reflux for 30 at a temperature of 30°C. Min, cool to 0°C, filter, and dry for 5 h at a temperature of 40°C to obtain 33.03 g of cefotaxime acid.

Embodiment 2

[0025] Mix 20.0 g of 7-ACA and 26.0 g of AE-active ester in 138.7 ml of dichloromethane and 21.3 ml of isopropanol, add 0.02 g of tetrabutylammonium bromide and 17 ml of triethylamine, and react with water for 1 h. Extract the organic phase twice, adjust the pH to 2.5-3.0 with hydrochloric acid, crystallize at room temperature for 1 h, and filter with suction to obtain 37 g of cefotaxime acid wet powder, add 111 ml of acetone, heat, and reflux at 30°C for 30 min. The temperature was lowered to 0°C, filtered, and dried at a temperature of 50°C for 4 hours to obtain 33.06 g of cefotaxime acid.

Embodiment 3

[0027] Mix 20.0 g of 7-ACA and 26.0 g of AE-active ester in 140 ml of dichloromethane and 20 ml of methanol, add 0.1 g of tetrabutylammonium chloride and 18 ml of triethylamine, and extract twice with water after reacting for 1 hour. For the organic phase, adjust the pH to 2.5-3.0 with hydrochloric acid, crystallize at room temperature for 1 h, and filter to obtain 37 g of cefotaxime acid wet powder, add 370 ml of acetone, heat, reflux for 30 min at a temperature of 30℃, and cool down To 0°C, filter, and dry for 3 h at a temperature of 65°C to obtain 33.04 g of cefotaxime acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com