Antibacterial hydrocolloid and preparation method of antibacterial hydrocolloid

A hydrocolloid and antibacterial water technology, applied in the field of medicine, can solve the problems of unclear negative biological effects and adverse reactions, application restrictions, etc., and achieve the effects of avoiding biological safety risks, preventing wound infection, and reducing pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

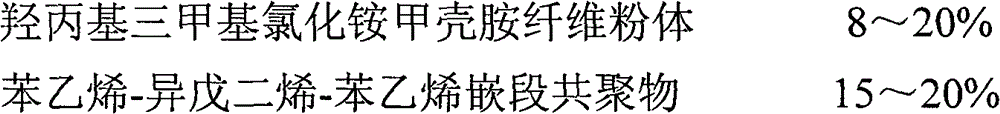

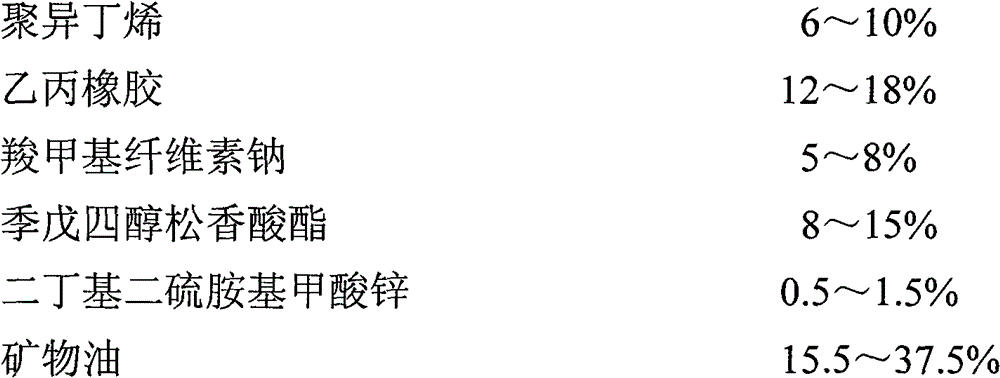

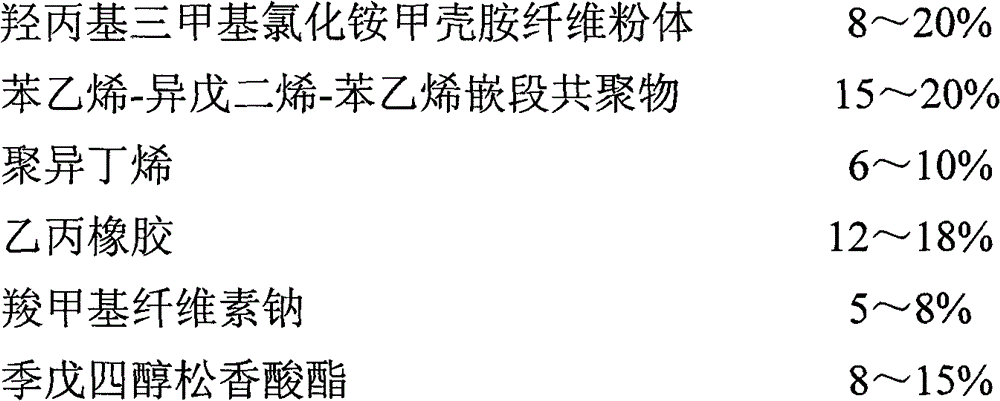

Method used

Image

Examples

preparation example Construction

[0032] Preparation of a hydroxypropyltrimethylammonium chloride chitosan fiber

[0033] Disperse chitosan fibers in isopropanol at a mass volume ratio of 1:20, and then add 2,3-epoxypropyl trimethyl chloride at a molar ratio of glucosamine residues of chitosan fibers of 1:4 ammonium, moved into a shaker, and oscillated evenly at room temperature to obtain a solid-liquid mixture of chitosan fibers. In the solid-liquid mixture of chitosan fibers, a sodium hydroxide solution with a concentration of 20wt% was added according to the chitosan fiber mass-volume ratio of 1:2. Shake the chitosan fiber reaction mixture evenly to obtain the chitosan fiber reaction mixture. After reacting the chitosan fiber reaction mixture in a constant temperature water bath at 90°C for 6.0 hours, separate the reacted chitosan fiber and wash it with 80v% ethanol aqueous solution and absolute ethanol in sequence. 2 times, the washed chitosan fibers were dried at 40°C to obtain hydroxypropyltrimethylammon...

Embodiment 1

[0048] Preparation of a hydroxypropyltrimethylammonium chloride chitosan fiber

[0049] Weigh 50g of chitosan fiber and disperse it in 1000mL of methanol, add 188g of 2,3-epoxypropyltrimethylammonium chloride, move it into a shaker, oscillate evenly at room temperature, then add 100g of NaOH solution with a concentration of 20wt%, Oscillate evenly at room temperature, react in a constant temperature water bath at 90°C for 6.0 hours, separate the reacted chitosan fibers, and wash them twice with 80v% ethanol aqueous solution and absolute ethanol in turn, and the washed chitosan fibers are at 40 drying under the condition of ℃ to obtain hydroxypropyltrimethylammonium chloride chitosan fiber with a substitution degree of 85%.

[0050] Preparation of b hydroxypropyl trimethyl ammonium chloride chitosan fiber powder

[0051] Weigh 50g of hydroxypropyltrimethylammonium chloride chitosan fiber and cut it into short fibers of 3mm with a fiber grinder, then process the short fibers in...

Embodiment 2

[0056] Preparation of a hydroxypropyltrimethylammonium chloride chitosan fiber

[0057] Weigh 50g of chitosan fiber and disperse it in 1000mL of methanol, add 188g of 2,3-epoxypropyltrimethylammonium chloride, move it into a shaker, oscillate evenly at room temperature, then add 100g of NaOH solution with a concentration of 20wt%, Oscillate evenly at room temperature, react in a constant temperature water bath at 90°C for 6.0 hours, separate the reacted chitosan fibers, and wash them twice with 80v% ethanol aqueous solution and absolute ethanol in turn, and the washed chitosan fibers are at 40 drying under the condition of ℃ to obtain hydroxypropyltrimethylammonium chloride chitosan fiber with a substitution degree of 85%.

[0058] Preparation of b hydroxypropyl trimethyl ammonium chloride chitosan fiber powder

[0059] Weigh 50g of hydroxypropyltrimethylammonium chloride chitosan fiber and cut it into short fibers of 4mm with a fiber grinder, then process the short fibers in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com