Soil conditioner containing calcium cyanamide and preparation method thereof

A soil conditioner, calcium cyanamide technology, applied in the fields of agriculture, soil conditioner and fertilizer, can solve the problems of reduced fertilizer efficiency, resource consumption, fertilizer efficiency decline, etc., to achieve balanced nitrogen and calcium ratio, significant killing effect, enhanced killing The effect of the extinction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First use a drum dryer to dry the straw powder and agricultural product processing waste to a water content of 6% to 13%, remove free water, take the above-mentioned dried straw powder 10kg, yeast processing wastewater concentrate, monosodium glutamate processing wastewater concentrate, One or more mixtures of tea leaves and furfural total 14kg, crush it into 1-3mm particles with a hammer mill, add 66kg of calcium cyanamide and 10kg of fried food waste oil, soybean oil or both After the mixture is stirred evenly, it is extruded and granulated with a double-roll extruder to make granules of 2 to 4 mm, then dried with a hot air dryer, then cooled with a drum machine, and measured and packaged.

Embodiment 2

[0029] First use a drum dryer to dry the straw powder and agricultural product processing waste to a water content of 6% to 13%, remove free water, take the above-mentioned dried straw powder 7kg, yeast processing wastewater concentrate, monosodium glutamate processing wastewater concentrate, One or more mixtures of tea residue and furfural total 8kg, crush it into 1-3mm particles with a hammer mill, add 72kg of calcium cyanamide and 13kg of fried food waste oil, soybean oil or both After the mixture is stirred evenly, it is extruded and granulated with a double-roll extruder to make granules of 2 to 4 mm, then dried with a hot air dryer, then cooled with a drum machine, and measured and packaged.

Embodiment 3

[0031] First use a drum dryer to dry the straw powder and agricultural product processing waste to a water content of 6% to 13%, remove free water, take the above-mentioned dried straw powder 15kg, yeast processing wastewater concentrate, monosodium glutamate processing wastewater concentrate, One or more mixtures of tea leaves and furfural total 27kg, crush it into 1-3mm particles with a hammer mill, add 50kg of calcium cyanamide and 8kg of fried food waste oil, soybean oil or both After the mixture is stirred evenly, it is extruded and granulated with a double-roll extruder to make granules of 2 to 4 mm, then dried with a hot air dryer, then cooled with a drum machine, and measured and packaged.

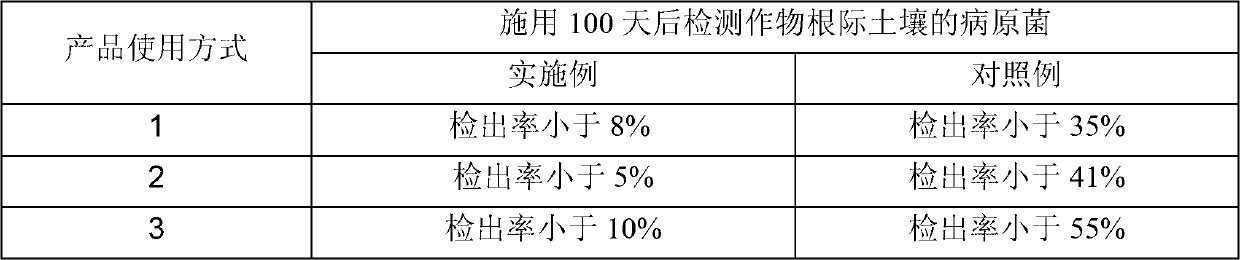

[0032] Using the water used in the traditional granulation molding process as a blending agent, to prepare 100kg of calcium cyanamide-containing soil conditioner as a reference example, the following comparison instructions are carried out:

[0033] Example

Carbon-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com