Catalytic synthesis method of L-theanine by using microorganism-produced gamma-glutamyl amino carboxamide synthase

A glutamine and synthetase technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as no breakthrough progress, achieve good development prospects, increase production, and simple cultivation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 Preparation of bacterial strain of the present invention

[0023] (1) Strain domestication

[0024] Samples were taken from the soil at 15-25 cm of the rhizosphere of tea trees in good growth conditions in the Gaoqiao Experimental Tea Field of the Hunan Tea Research Institute, and 10 g of fresh soil samples were put into a triangular flask containing 90 mL of sterile water, dispersed with glass beads, and placed in a In a constant temperature shaker, shake at 25°C and 150 r / min for 1 hour to make a soil suspension and let it stand. Add the soil suspension supernatant to the screening medium at a volume ratio of 2%, and after 5-14 days of shaking culture at 30°C and 150 r / min, transfer the turbid medium (OD610 value greater than 0.1) to a fresh screening medium , and then cultivated until turbid, and this process was repeated 3-5 times to obtain the acclimatized bacteria liquid.

[0025] (2) Isolation and purification of bacterial strains

[0026] The acc...

Embodiment 2

[0027] Example 2 Preparation of γ-glutamine synthetase

[0028] Take the above-obtained slant strain, pick a ring and put it in 40mL enrichment medium, culture it with shaking at 30°C and 150r / min for 3 days, and check that the OD value is greater than 0.1. Then centrifuge the enriched culture solution at 4°C and 12000r / min for 18min, discard the supernatant, soak it twice with 10 mmol / L phosphate buffer solution of pH 6.0, then centrifuge at 4°C and 12000r / min for 18min, discard Supernatant, then resuspend the obtained cells in a small amount of buffer (it is enough to cover the cells), and then perform ultrasonic cell disruption on ice (20 kHZ, 2-3 min) to make a crude enzyme solution.

[0029] Adjust the pH value of the crude enzyme solution to 8, add ammonium sulfate with 30% saturation at 30°C for salting out, redissolve with the heavy protein precipitation solution to the original volume, and perform SephadexG-75 column chromatography after ultrafiltration and desalinati...

Embodiment 3

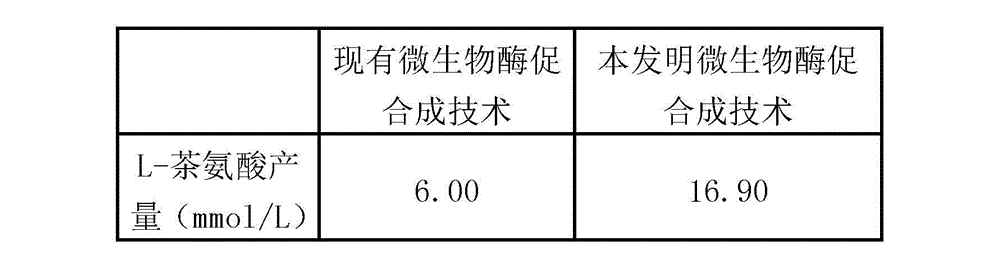

[0031] Example 3 Synthesis of L-theanine catalyzed by γ-glutamine synthetase

[0032] Add the purified γ-glutamine synthetase to the test tube equipped with the L-theanine synthesis system at the ratio of 0.02 mL of γ-glutamine synthetase per liter of L-theanine synthesis system, After reacting for 12 hours at 30°C and a pH value of 8, the test tube was immersed in boiling water to terminate the reaction. After cooling to room temperature, centrifuge at 12000r / min for 5 minutes, and take the supernatant to obtain L-theanine, which was stored at -20°C.

[0033] Among them, the synthesis system of L-theanine is: 30 mmol / L glutamic acid, 150 mmol / L ethylamine hydrochloride, 15 mmol / L ATP, 30 mmol / L MgCl 2 , 100 mmol / L imidazole buffer (pH7.75), and 0.1 mg / mL CTAB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com