Foamed ball for producing foam slag in process of stainless steel smelting by an electric arc furnace and a manufacture method thereof

A manufacturing method and technology for foaming balls, which are applied to electric furnaces, furnaces, furnace types, etc., can solve the problems of inability to effectively create foamed slag, inconvenient use, splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

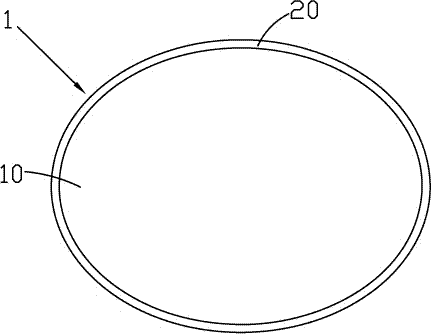

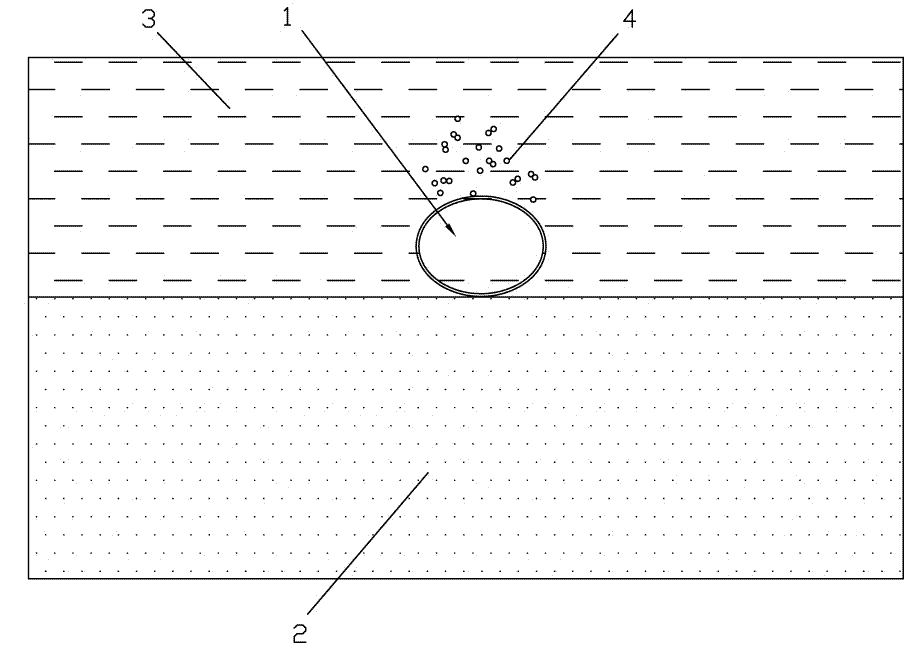

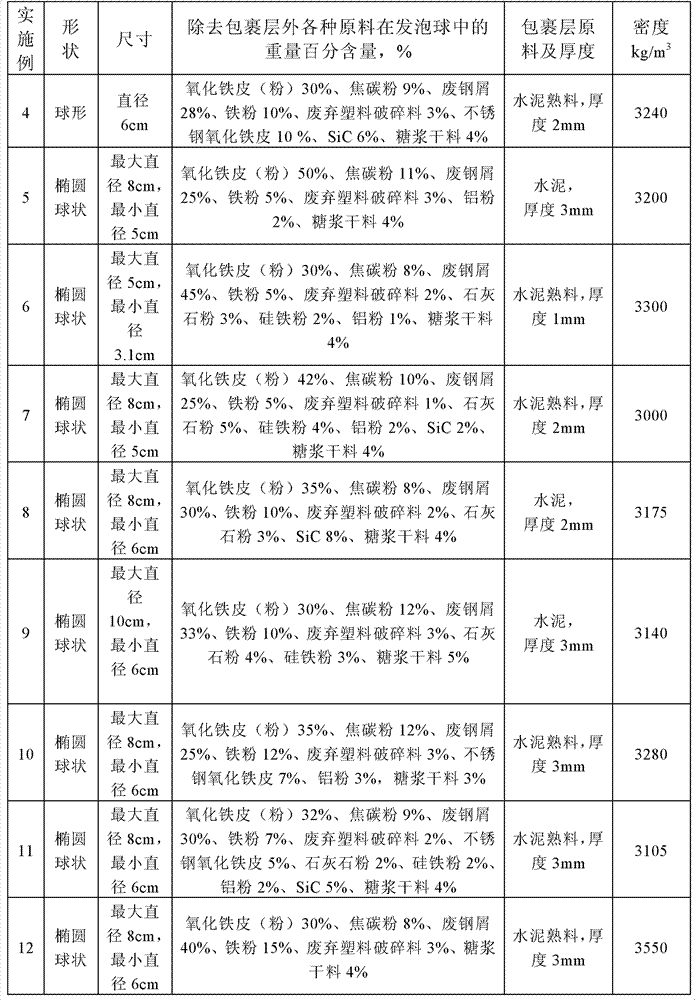

Embodiment 1

[0086] The foaming balls made of foaming slag in the process of smelting stainless steel mother liquor in an electric furnace are applied on a 100-ton electric furnace, and the slag has been melted and added in the late stage of scrap steel melting. This foamed ball is ellipsoidal, maximum diameter 9cm, minimum diameter 6cm, wrapping layer thickness 3mm, removes various raw materials outside the wrapping layer and their weight percentages in foaming ball are respectively: iron oxide scale (powder) 35%, Coke powder 12%, steel scrap 30%, iron powder 10%, waste plastic crushing 3%, limestone powder 4%, SiC 2%, syrup dry material 4%, and the coating layer is the hard shell of cement clinker hardened. The density is 3175kg / m 3 .

[0087] Prepare raw materials before making foam balls. Raw material requirements: powdery or granular raw materials with a diameter of less than 2mm, broken pieces for waste plastic crushed materials, whose diameter is required to be less than 3cm, and t...

Embodiment 2

[0097] The foaming balls of foaming slag made in the process of smelting stainless steel mother liquor in electric furnace are applied on a 100-ton electric furnace and added in the refining period (the stage after the scrap steel has been completely melted). This foamed ball is ellipsoidal, maximum diameter 10cm, minimum diameter 7cm, wrapping layer thickness 3mm, removes various raw materials outside the wrapping layer and their weight percentages in foaming ball are respectively: iron oxide scale (powder) 40%, Coke powder 11%, steel scrap 25%, iron powder 10%, waste plastic crushed material 3%, stainless steel oxide scale 5%, SiC 2%, syrup dry material 4%, the coating layer is the hardened cement clinker shell. The density is 3275kg / m 3 .

[0098]Prepare raw materials before making foam balls. Raw material requirements: powdery or granular raw materials with a diameter of less than 2mm, broken pieces for waste plastic crushed materials, whose diameter is required to be le...

Embodiment 3

[0108] The foaming balls of foaming slag in the process of smelting stainless steel mother liquor in electric furnace are applied on a 100-ton electric furnace, and added after the slag is reduced by the reducing agent ferrosilicon or aluminum. This foaming ball is ellipsoidal, maximum diameter 8cm, minimum diameter 5cm, wrapping layer thickness 2mm, removes its various raw materials outside wrapping layer and its weight percentage in foaming ball is respectively: iron oxide skin (powder) 30% , coke powder 8%, scrap steel shavings 25%, iron powder 15%, waste plastic scrap 3%, stainless steel oxide scale 5%, SiC 10%, syrup dry material 4%, and the coating layer is the hardened cement clinker. shell. The density is 3225kg / m 3 .

[0109] Prepare raw materials before making foam balls. Raw material requirements: powdery or granular raw materials with a diameter of less than 2mm, broken pieces for waste plastic crushed materials, whose diameter is required to be less than 3cm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com