Method and device for preparing tin methane sulfonate through hydrogen-free electrolysis

A technology of stannous methanesulfonate and methanesulfonic acid, applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of low hydrogen explosion limit, serious environmental pollution, short production cycle, etc., and achieve energy consumption And the effect of low cost, high product purity and saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

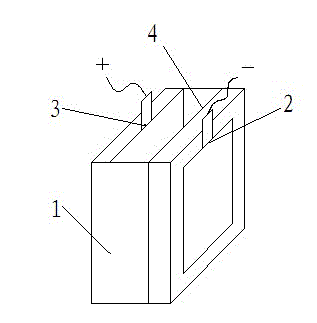

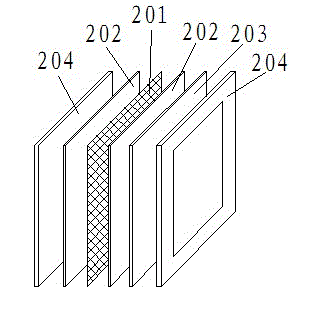

[0027] Example 1: A method for preparing stannous methanesulfonate by hydrogen-free electrolysis, in such as figure 1 In the shown a clean hydrogen-free electrolysis stannous methanesulfonate device, the electrolytic cell 1 is a polypropylene material plate and frame diaphragm electrolytic cell, the anode is a solid tin anode, and the anode area is 0.15m 2 , the cathode is a gas diffusion electrode, the metal conductive substrate of the gas diffusion electrode is copper mesh, the waterproof layer is carbon and polytetrafluoroethylene film, the catalytic layer is a porous carbon film, and the cathode area is 0.1m 2 , the cathode and the anode are separated by a polymer anion exchange membrane, and 2% and 30% methanesulfonic acid solutions are added to the anode chamber and the cathode chamber respectively, and electrolyzed at a constant current of 20A (gas diffusion electrode current is 200A / m 2 ), the temperature of the electrolyte is controlled at 20-30°C, the current wil...

Embodiment 2

[0028] Embodiment 2-7: By the method of embodiment 1, the gas diffusion electrode in embodiment 1 is replaced with the following electrodes of the same area respectively, electrolytically prepares stannous methanesulfonate, embodiment 2-uses tin plate; Embodiment 3-gas diffusion cathode catalysis layer containing MnO 2 Catalyst; Embodiment 4-air cathode catalytic layer contains Pt black catalyst; Metal conductive base material among the embodiment 1 is replaced copper with embodiment 5-nickel mesh, embodiment 6-titanium mesh and embodiment 7-brass mesh respectively The net prepared stannous methanesulfonate, the experimental results are shown in Table 1.

[0029]

[0030] The results compared with Example 2 show that the use of air cathode not only avoids the generation of hydrogen, but also reduces the cell voltage by 0.6-1.50V, reducing power consumption.

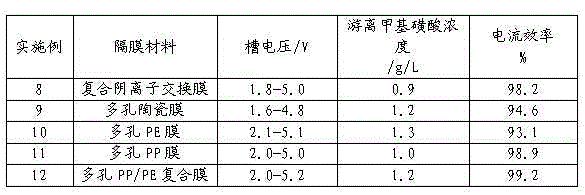

Embodiment 8-12

[0031] Embodiment 8-12: By the method for embodiment 1, diaphragm in embodiment 1 is replaced with the following diaphragm of same area respectively, electrolytically prepares tin protosulfonate, embodiment 8-composite anion exchange membrane, embodiment 9-porous ceramic membrane, implement Example 10-Porous PE film (thickness 1mm), porous PP film (thickness 1mm), porous PP / PE composite film (thickness 1mm), the experimental results are shown in Table 2.

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com