Biodegradable zinc (or zinc alloy) and porous biphase calcium phosphate composite material and preparation method thereof

A technology of biphasic calcium phosphate and porous calcium phosphate, applied in medical science, prosthesis, etc., can solve problems such as limitation, low toughness, and sudden large-scale release, achieve good mechanical stability and strength, maintain connectivity, and improve The effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

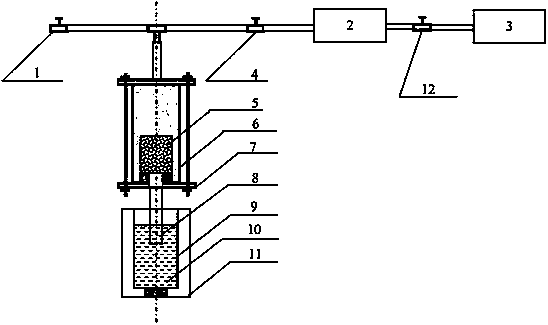

Method used

Image

Examples

Embodiment 1

[0025] Preparation of biodegradable zinc and biphasic calcium phosphate composites with 95% porosity and 10% HA, the steps are as follows:

[0026] (1) Preparation of porous biphasic calcium phosphate (β-TCP / HA) preform containing 10% HA;

[0027] ① Preparation of HA, β-TCP powder. a 250g calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and 100g diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) were dissolved in deionized water to form 0.4mol / l and 0.3mol / l aqueous solutions; b. 0.4mol / l calcium nitrate aqueous solution was heated to 40°C in a constant temperature magnetic stirrer, and then 0.3mol / l phosphoric acid Diammonium hydrogen aqueous solution is dripped at a rate of (2-3) ml / min, and the pH value of the reaction solution is adjusted by ammonia water (HA: pH is about 10; β-TCP: pH is about 5.5-6); c according to Ca / P=1.48 After the titration, continue to stir at 40°C for half an hour, let it stand still, and settle naturally for 24h; c. Wash and centrifuge the precipitate, ...

Embodiment 2

[0039] Preparation of biodegradable Zn-Mg alloy and biphasic calcium phosphate composite with 95% porosity and 35% HA. The steps are as follows:

[0040] (1) Prepare a porous biphasic calcium phosphate preform containing 35% HA in the same manner as in Example 1. The difference is that when preparing HA and β-TCP slurry, the amount of HA powder added is 17.5 g, and the amount of β-TCP powder added is 32.5 g.

[0041] (2) Suction-cast Zn-3Mg alloy according to the same method as in Example 1, the difference is that the molten alloy is a Zn-3Mg alloy (that is, the weight percentage of Mg is 3%, and the rest is Zn), and at 650°C Keep warm and set aside.

[0042] From the observation of the structure of the composite material, it can be seen that the interface between the dual-phase calcium phosphate and the Zn-3Mg alloy is well combined, and the structure of the composite material is compact, while maintaining the respective connectivity of the dual-phase calcium phosphate and ...

Embodiment 3

[0044] Biphasic calcium phosphate composites with biodegradable zinc-yttrium alloy and 90% porosity and 50% HA were prepared. The steps are as follows:

[0045] (1) Prepare a porous biphasic calcium phosphate preform containing 50% HA in the same manner as in Example 1. The difference is that when preparing HA and β-TCP slurry, the addition amount of HA powder is 25g, and the addition amount of β-TCP powder is 25g. When preparing the porous biphasic calcium phosphate preform, the polyurethane foam was dipped and extruded four times in HA and β-TCP slurry.

[0046] (2) Suction-cast Zn-2Y alloy according to the same method as in Example 1, the difference is that the molten alloy is a Zn-2Y alloy (that is, the weight percentage of Y is 2%, and the rest is Zn), and at 600 ° C Keep warm and set aside.

[0047] From the observation of the structure of the composite material, it can be seen that the interface of the biphasic calcium phosphate and the Zn-2Y alloy is well combined, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com