EVA (ethylene vinyl acetate copolymer) packaging adhesive film capable of improving light spectrum conversion efficiency of solar cell module

A solar cell and spectrum conversion technology, applied in electrical components, circuits, adhesives, etc., can solve the problems of increasing the burden of backplane protection, not being able to significantly improve the photoelectric conversion efficiency of cells, and reducing the service life of components, so as to improve photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

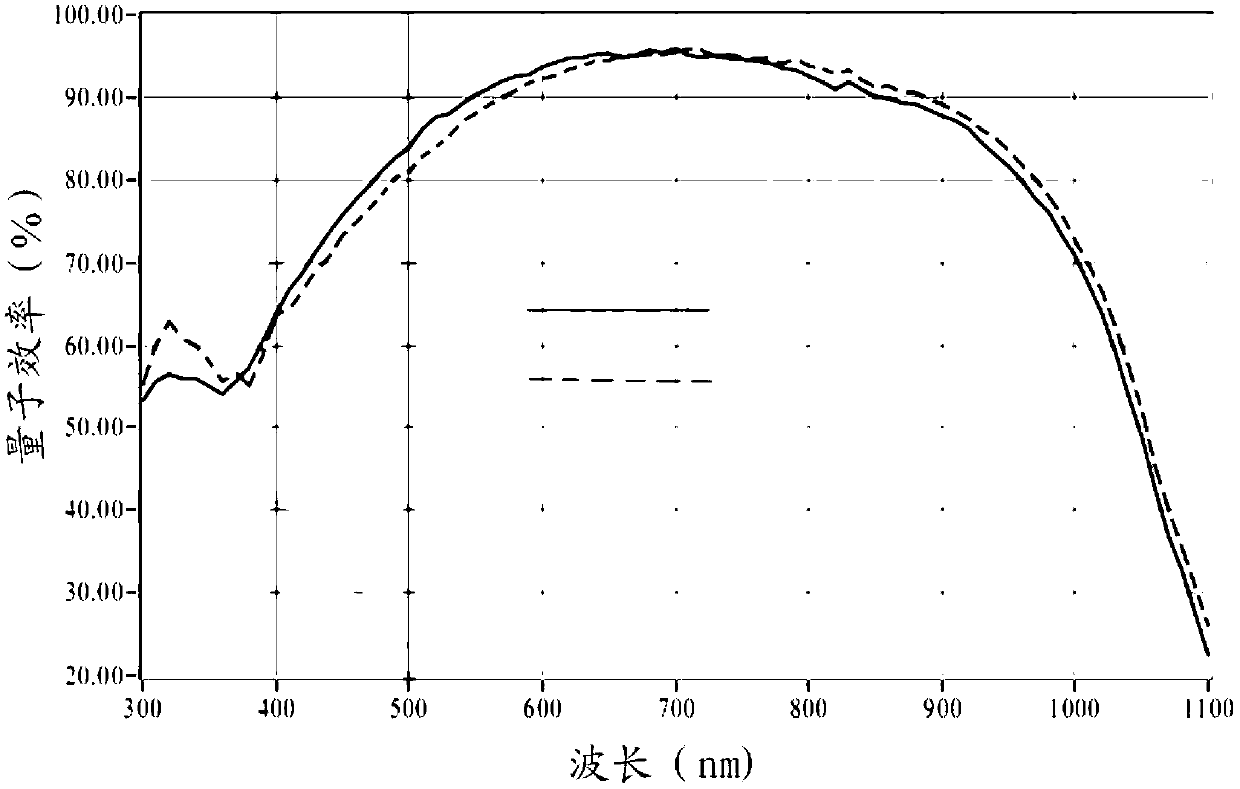

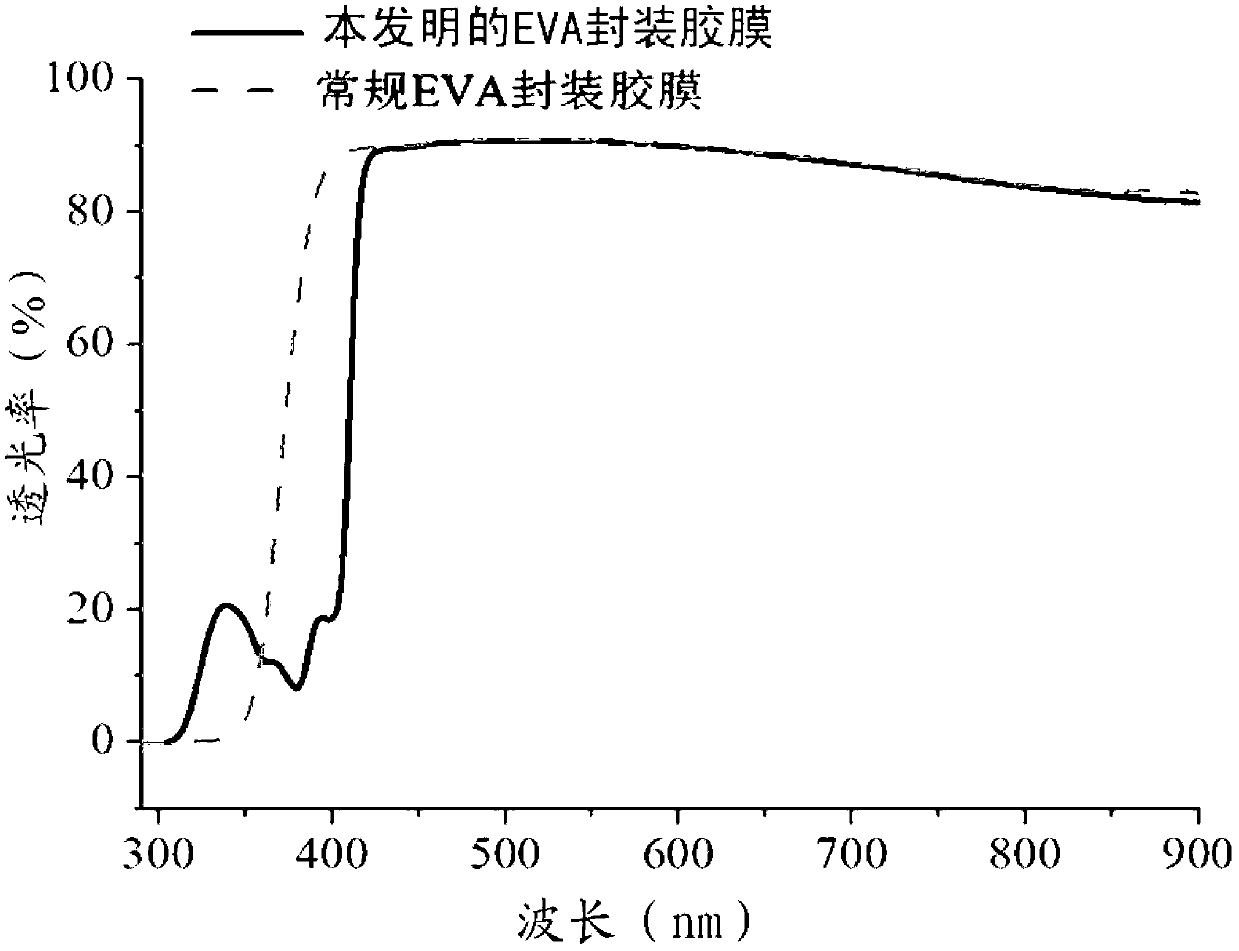

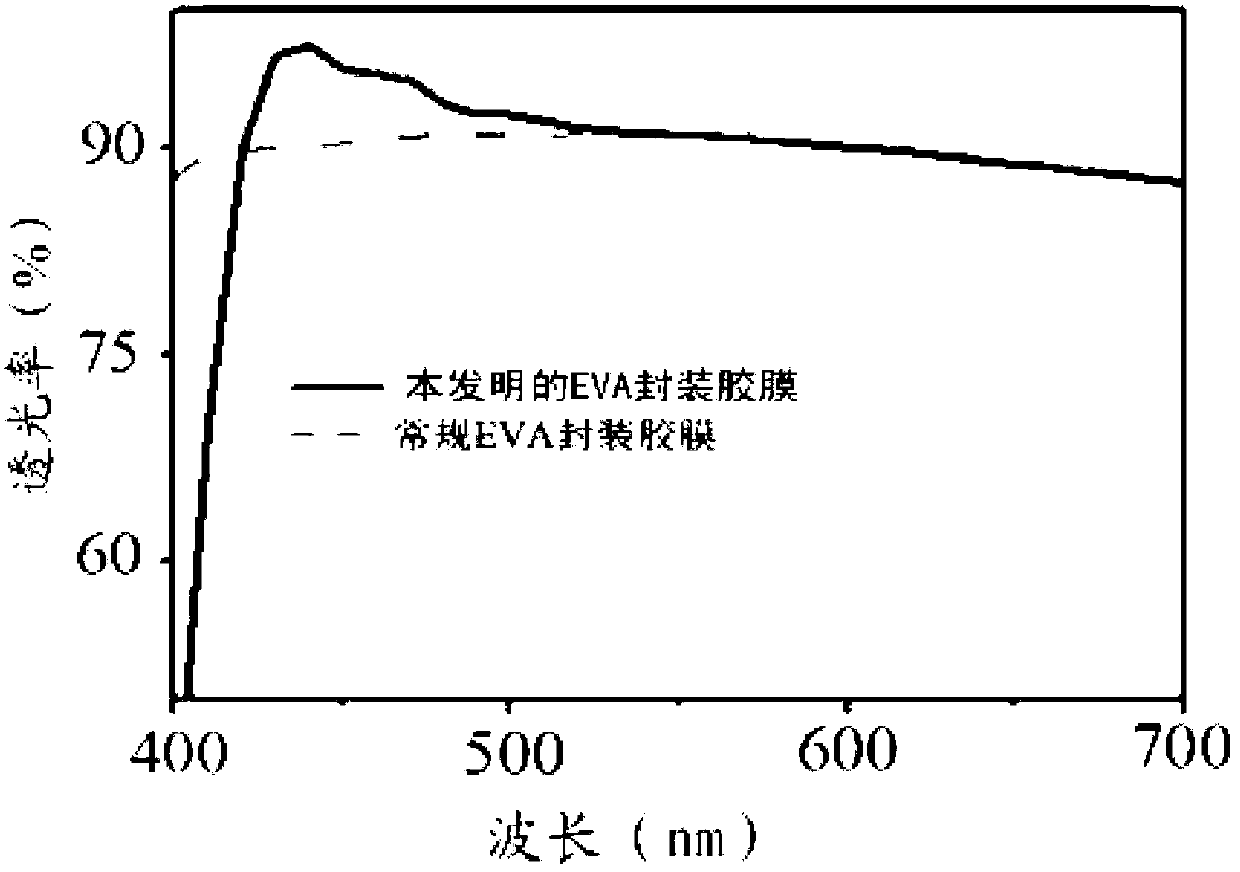

[0048] A kind of EVA encapsulating adhesive film that improves the spectral conversion efficiency of solar cell module, it is that 100 mass parts vinyl acetate content is 28%, melt index is 30g / 10min EVA raw material, adds 0.5 parts of cross-linking agent tert-butyl peroxide 2-ethylhexyl carbonate, 0.5 parts of m-phenylbismaleimide, an auxiliary cross-linking agent, 0.5 parts of antioxidant tris(nonylphenyl) phosphite, 0.1 parts of UV absorber 2-(2 '-Hydroxy-5'-tert-octylphenyl) benzotriazole, 1 part light stabilizer bis 2,2,6,6-tetramethyl-4-pyridinol fatty acid ester, 0.3 part coupling agentγ -(Methacryloyloxy)propyltrimethoxysilane, 0.005 parts of spectral conversion material 2,5-bis(5-tert-butyl-2-benzoxazolyl)thiophene, mixed uniformly through a mixer, Put it into the casting machine, at 80 ℃, through plasticizing extrusion, stretching, traction, winding to make an EVA film with a thickness of about 0.1mm.

Embodiment 2

[0050] A kind of EVA encapsulating adhesive film that improves the spectral conversion efficiency of solar cell module, it is that 100 mass parts vinyl acetate content is 33%, and melt index is 25g / 10min EVA raw material, adds 1.0 parts of cross-linking agent diphenyl peroxide Acyl, 0.3 parts of co-crosslinking agent ethylene glycol dimethacrylate, 0.4 parts of antioxidant tris(nonylphenyl) phosphite, 0.5 parts of UV absorber 2-hydroxy-4-n-octyloxydiphenyl Methanone, 0.1 part light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.8 part coupling agent γ-glycidyl etheroxypropyl trimethoxysilane , 0.01 part of the spectral conversion material distyryl bisbenzoxazole, mixed evenly by the mixer, put into the casting machine, at 80 ℃, plasticized extrusion, stretching, pulling, winding to make a thickness of about 0.5mm EVA film.

Embodiment 3

[0052] A kind of EVA encapsulation adhesive film that improves the spectral conversion efficiency of solar cell module, it is that 100 mass parts vinyl acetate content is 28%, melt index is 30g / 10min EVA raw material, adds 0.8 parts of cross-linking agent diisopropyl peroxide Benzene, 0.9 parts of co-crosslinking agent ethylene glycol dimethacrylate, 0.1 part of antioxidant triphenyl phosphite, 0.3 parts of UV absorber 2-hydroxy-4-n-octyloxybenzophenone, 0.2 parts Light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.5 part coupling agent γ-glycidyl etheroxypropyl triethoxysilane, 0.05 part spectrum The conversion material 2,5-bis(5-tert-butyl-2-benzoxazolyl)thiophene is mixed evenly by a mixer, put into a casting machine, and plasticized, extruded, stretched, Traction and winding are made into an EVA film with a thickness of about 0.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com