Method for preparing cyclohexane by catalyzing and hydrogenising benzene at room temperature

A technology for catalytic hydrogenation and cyclohexane, applied in the directions of hydrogenation to hydrocarbons, chemical recovery, etc., can solve the problems of harsh reaction conditions, low industrial application value and high loading capacity, and achieve high cyclohexane selectivity and yield, Huge industrialization prospects, the effect of high TOF value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

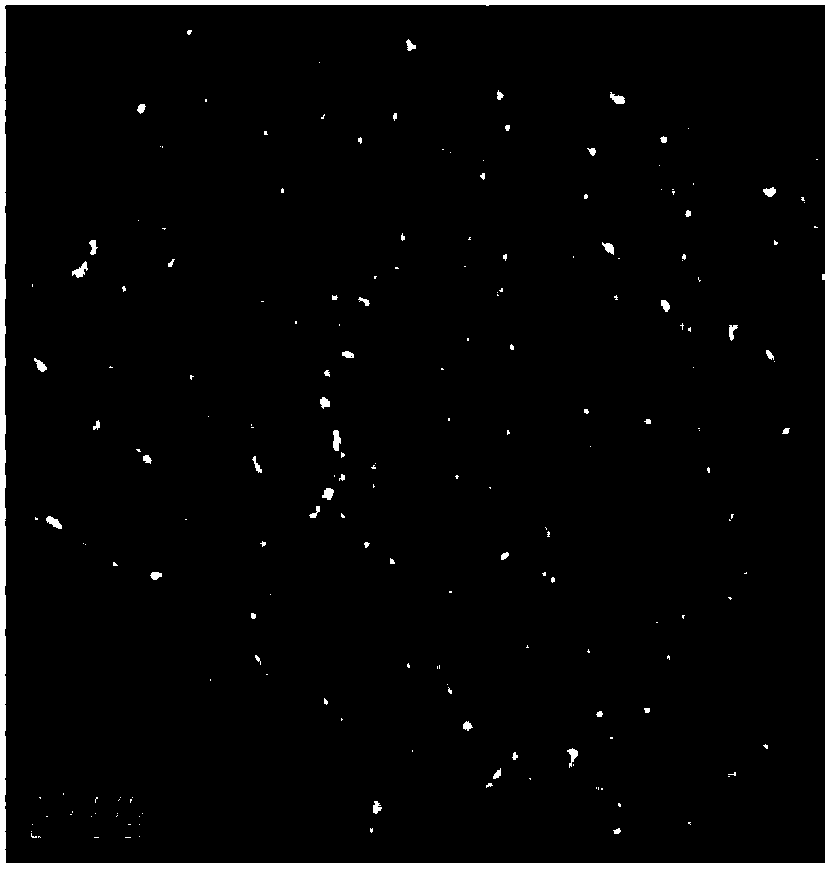

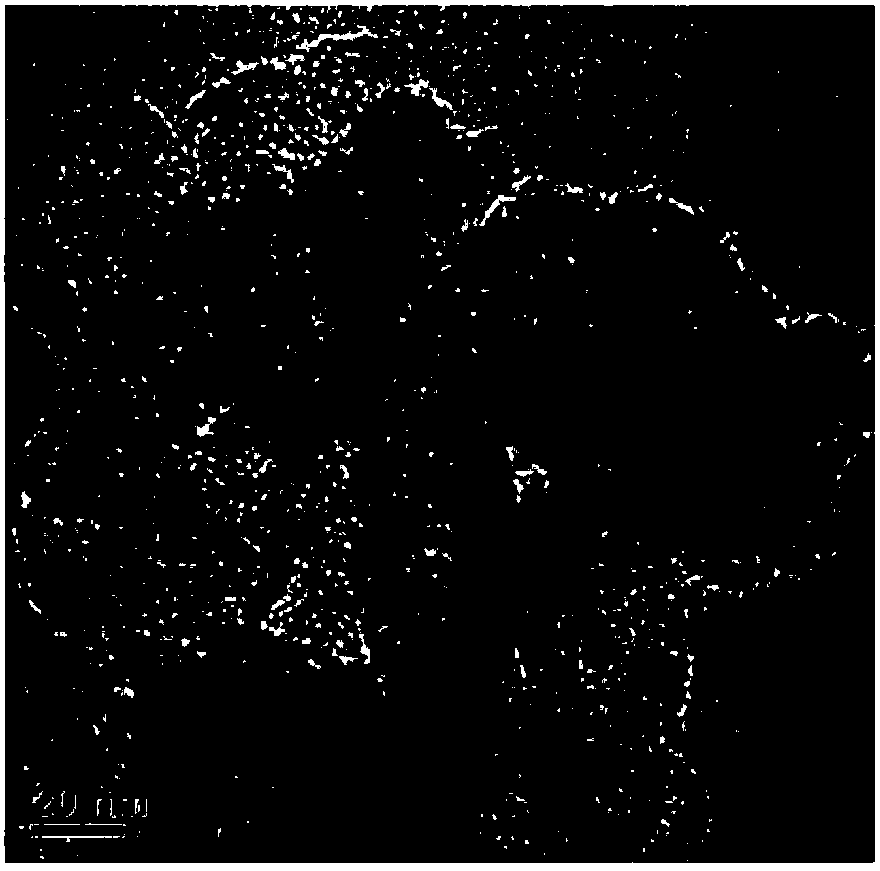

[0029]Synthesis of NiRu / C catalyst:

[0030] 1. Weigh (0.45~1.8g) of NiCl 2 ·6H 2 O, dissolved in (45~90mL) deionized water and stirred at room temperature to obtain a clear solution.

[0031] 2. Add (5~15mL) ethanol to the above NiCl 2 ·6H 2 O solution.

[0032] 3. Add (5~25mL) the mass fraction of 85% reducing agent solution (sodium borohydride, sodium hypophosphite, hydrazine hydrate, ascorbic acid, or polyol such as ethylene glycol).

[0033] 4. Add (0.25~1.25g) activated carbon.

[0034] 5. Heat the reaction solution to (100~200℃) to load the metal on the activated carbon.

[0035] 6. Filter and wash several times with ethanol and water, respectively.

[0036] 7. Dry under vacuum and keep at 60°C for 6h.

[0037] 8. Weighing to obtain Ni / C nanomaterials, which are added to RuCl with a mass fraction of 0.15% 3 In the solution, in-situ reduction was performed, filtered, washed, dried in vacuo, and kept at 60 °C for 6 h.

[0038] 10. The catalyst is at (600~800℃) t...

Embodiment 2

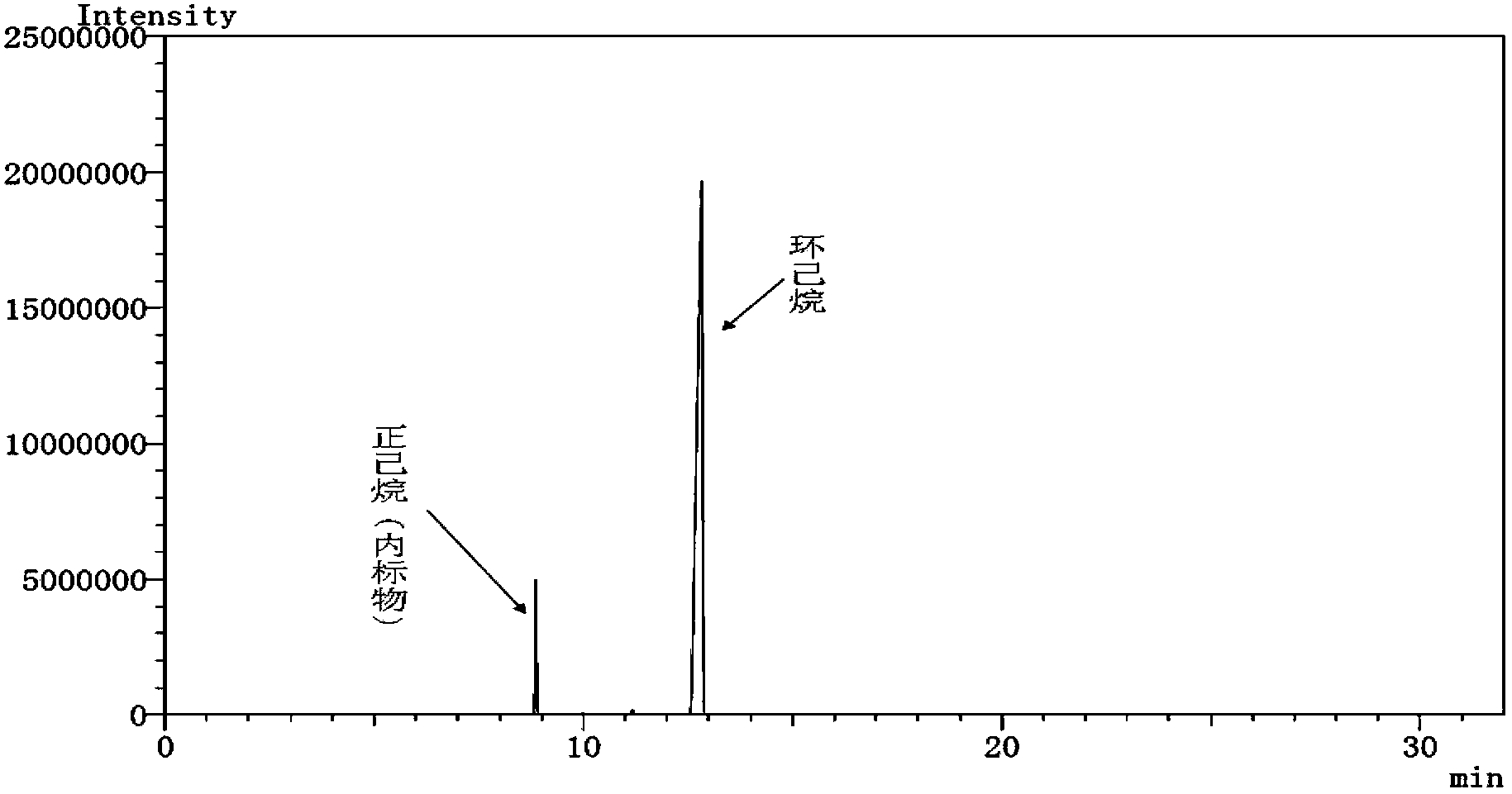

[0041] In a high-pressure stirred tank reactor (Parr4848 type, 300mL), add catalyst 0.17% NiRu / C catalyst 0.200g, benzene 10.0mL in turn; pass nitrogen (purity ≥99.999%) to remove the air in the kettle; pass hydrogen ( Purity ≥99.999%) to remove nitrogen in the kettle, close the outlet valve, and continue to feed hydrogen, when the reaction pressure is 4.8MPa. Start stirring, the stirring rate is 500 r / min, and the reaction is performed at a constant temperature of 30 °C for 6 hours. After the reaction is stopped, the remaining gas is discharged, and the product is obtained by centrifugation. The composition of the product is analyzed by gas chromatography. The yield of alkane was 100%, and the TOF of the catalyst was 5604.8 mol benzene / mol Ru·h. In addition, the catalyst was repeatedly used for 10 times, and no decrease in its selectivity and activity was observed.

Embodiment 3

[0043] In a high-pressure stirred tank reactor (Parr4848 type, 300mL), add catalyst 0.17% NiRu / C catalyst 0.200g, benzene 10.0mL in turn; pass nitrogen (purity ≥99.999%) to remove the air in the kettle; pass hydrogen ( Purity ≥ 99.999%) to remove nitrogen in the kettle, close the outlet valve, and continue to introduce hydrogen, when the reaction pressure is 1.0MPa. Start stirring, the stirring rate is 500 r / min, and the constant temperature reaction is 30 °C for 5.5 hours. After the reaction is stopped, the remaining gas is discharged, and the product is obtained by centrifugation. The composition of the product is analyzed by gas chromatography. The yield of hexane was 65%, and the TOF of the catalyst was 3910.6 mol benzene / mol Ru·h. In addition, the catalyst was repeatedly used for 10 times, and no decrease in its selectivity and activity was observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com