Facility for manufacturing vertical GaN-based LED chips by metal substrates

A technology of LED chips and metal substrates, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of unreasonable layout of gas phase material introduction into reaction chamber, lack of mass flow controller, and improper installation of instruments Reasonable and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

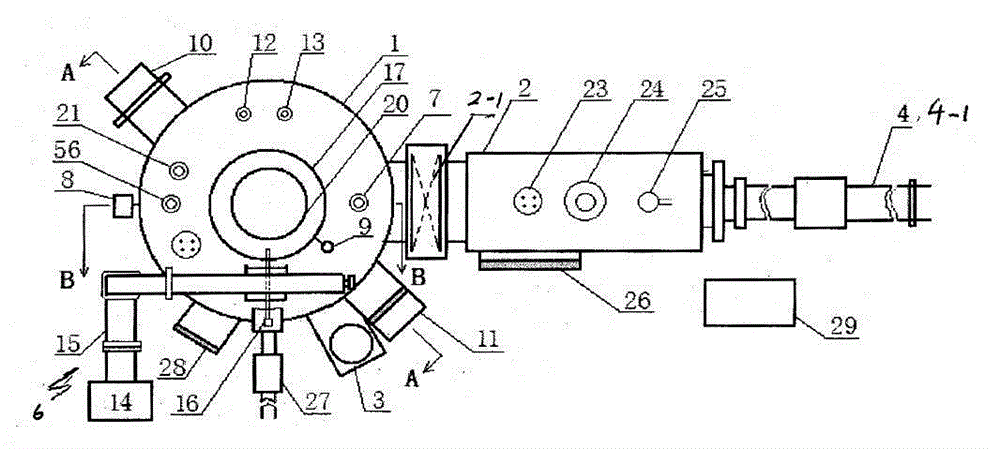

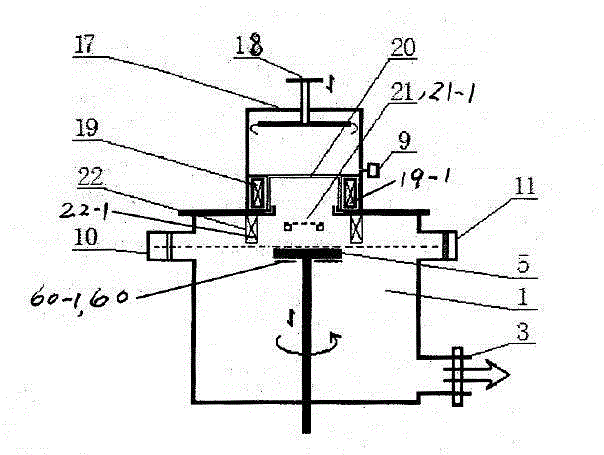

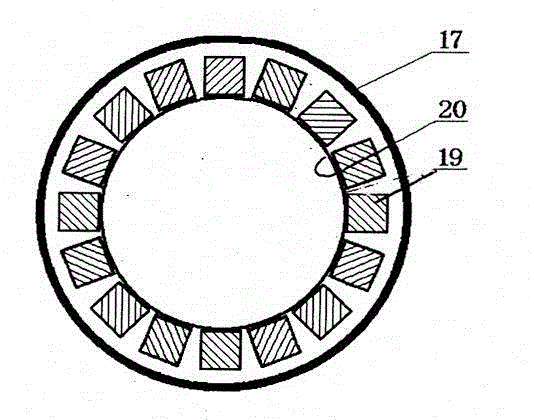

[0039] A typical specific implementation is as attached Figure 1~4 shown.

[0040] A device for preparing vertical GaN-based LED chips using a metal substrate, comprising:

[0041] A computer information acquisition controller 29;

[0042] A reaction chamber 1; in the reaction chamber 1, a mechanical rotary metal substrate table 5 arranged concentrically with the reaction chamber 1 that can move up and down; on the metal substrate table 5, a carbon wire electric heating device 60 is provided; The bottom of the reaction chamber 1 is connected to the pipeline of the vacuum equipment 3, and the negative pressure can be formed in the reaction chamber 1 through the vacuum equipment 3;

[0043] A metal substrate charging chamber 2 including a charging door 26; one end of the metal substrate charging chamber 2 is provided with a magnetic / pneumatic feeding device 4, and the other end is connected to a computer information acquisition controller 29 The electrically connected magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com