Alkaline-earth metal silicide preparation method

A technology of alkaline earth metals and silicides, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of Mg or Ca volatilization and loss of Si, poor product phase uniformity, and low product purity, and achieve easy operation, low cost, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a glove box with an argon atmosphere, weigh MgH at a molar ratio of 2:1 2 and Si samples, put them into a ball mill jar, the ball-to-material ratio is 60:1, and the grinding balls are stainless steel balls, which will contain MgH 2 Put the ball mill jar of the mixture with Si on the planetary ball mill, and ball mill it at a speed of 300 rpm for 8 hours to obtain 2MgH 2 -Si mixture. 2MgH 2 -Si mixture is heated in vacuum to dehydrogenate, the heating rate is 2 degrees Celsius / min, after heating to 400 degrees Celsius, heat preservation for 4 hours and vacuumize the system, then furnace cooling to room temperature, the resulting sample from argon The atmosphere of the glove box was taken out to obtain Mg 2 Si sample.

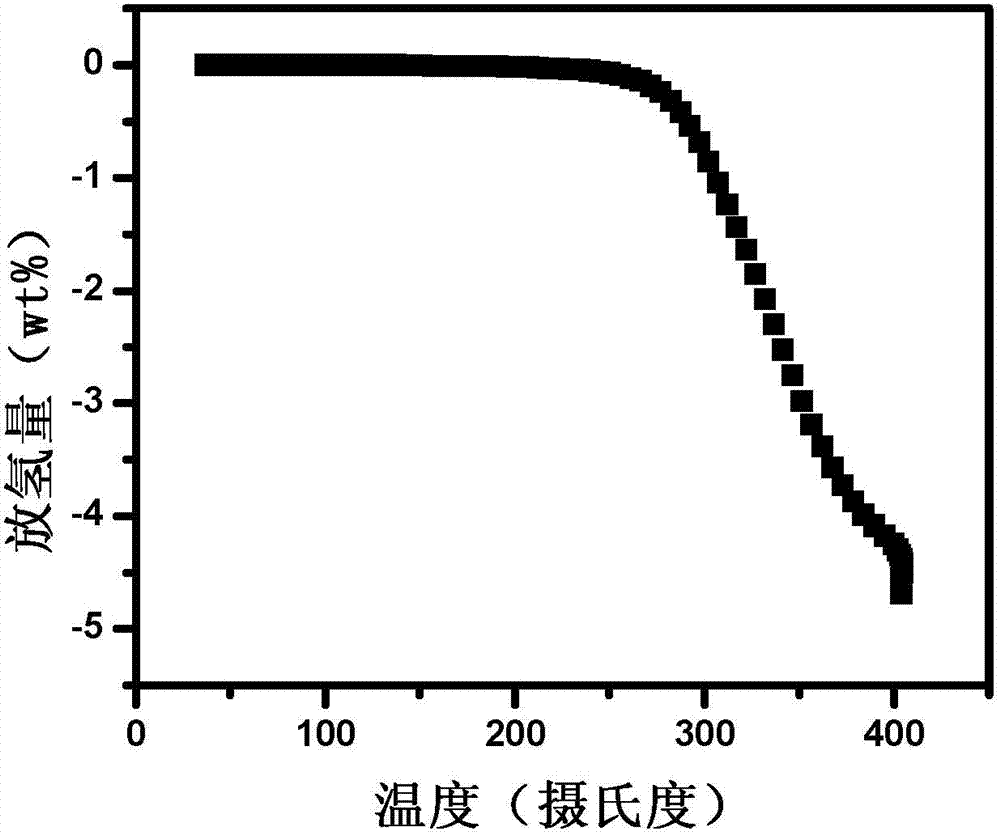

[0029] figure 1 2MgH after ball milling 2 -The hydrogen desorption curve of the Si mixture varies with temperature. It can be seen from the figure that the initial temperature of the dehydrogenation reaction is around 200 degrees Celsius, and the ...

Embodiment 2

[0031] In a glove box with an argon atmosphere, weigh MgH at a molar ratio of 2:1 2 and Si samples, put them into a ball mill jar, the ball-to-material ratio is 90:1, and the balls are zirconia balls, which will contain MgH 2 Put the ball mill jar of the mixture with Si on the planetary ball mill, and ball mill for 4 hours at a speed of 400 rpm to obtain 2MgH 2 -Si mixture. 2MgH 2 -Si mixture is heated in vacuum to dehydrogenate, the heating rate is 10 degrees centigrade / minute, after heating to 400 degrees centigrade, keep warm for 4 hours and vacuumize the system, then furnace cool down to room temperature, and the obtained sample is decomposed from argon The atmosphere of the glove box was taken out to obtain Mg 2 Si sample.

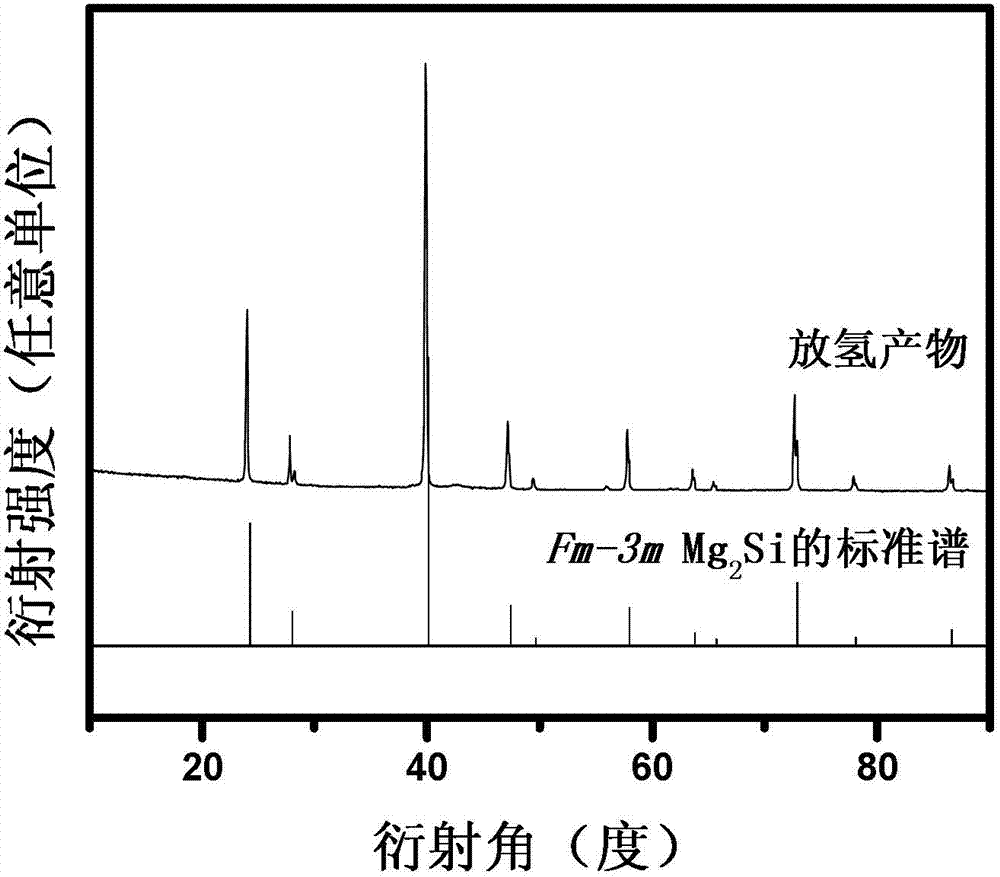

[0032] figure 2 2MgH 2 The XRD pattern (X-ray diffraction pattern) of the product after the Si mixture is heated to release hydrogen, as can be seen from the figure, the hydrogen release product is Mg of the Fm-3m space group 2 Si crystal, the...

Embodiment 3

[0034] In a glove box with an argon atmosphere, weigh MgH at a molar ratio of 2:1 2 and Si samples, put them into a ball mill jar, the ball-to-material ratio is 120:1, and the grinding balls are stainless steel balls, which will contain MgH 2 Put the ball mill jar of the mixture with Si on the planetary ball mill, and ball mill for 2 hours at a speed of 600 rpm to obtain 2MgH 2 -Si mixture. 2MgH 2 -Si mixture is heated in vacuum to dehydrogenate, the heating rate is 10 degrees centigrade / minute, after heating to 400 degrees centigrade, keep warm for 4 hours and vacuumize the system, then furnace cool down to room temperature, and the obtained sample is decomposed from argon The atmosphere of the glove box was taken out to obtain Mg 2 Si sample.

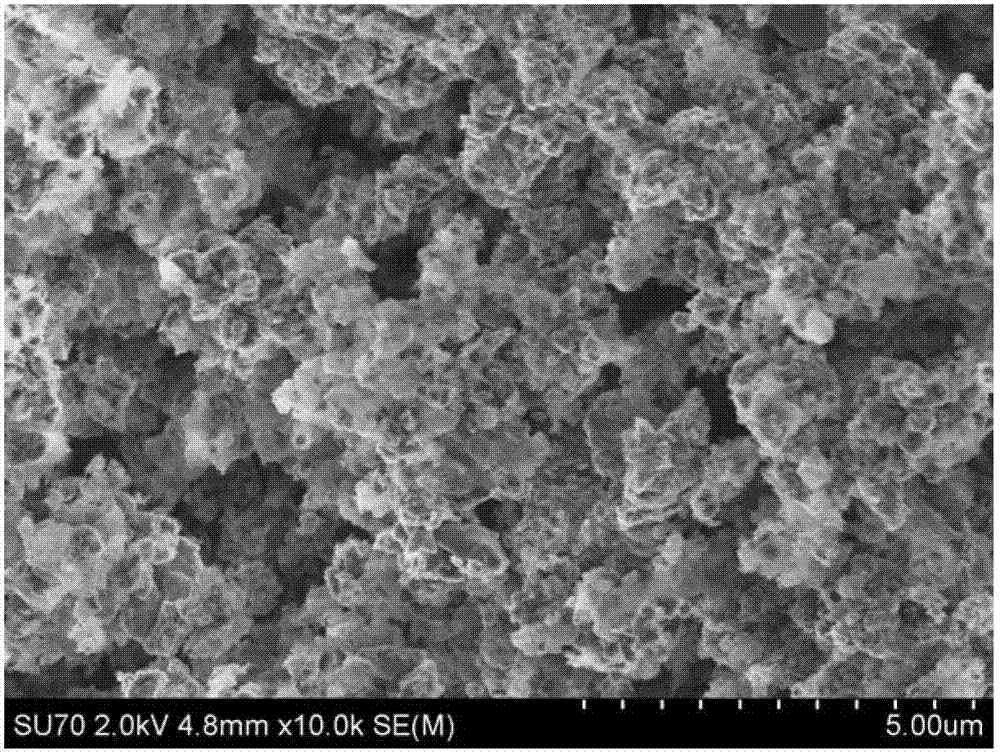

[0035] image 3 2MgH 2 The scanning electron micrograph of the product after the Si mixture is heated to dehydrogenate, the scanning electron micrograph shows that the particles are submicron in size and flocculent after agglome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com