Method for removing COD (chemical oxygen demand) and ammonia nitrogen from wastewater by using titanium-base lead peroxide composite electrode

A composite electrode and lead dioxide technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve problems such as easy generation of oxygen and chlorine, reduce electro-oxidation current efficiency, etc., to reduce treatment cost, cost reduction, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Biochemical effluent treatment of a fine chemical plant, realized by:

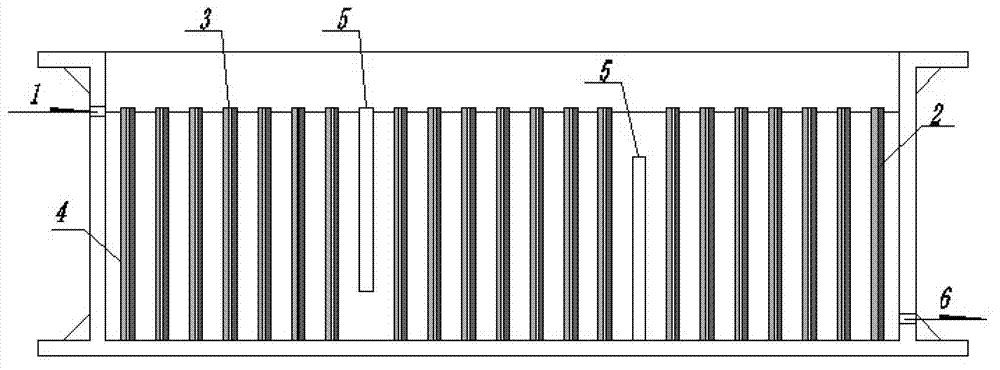

[0045] The schematic diagram of the actual electrolyzer is as Figure 1-Figure 4 as shown,

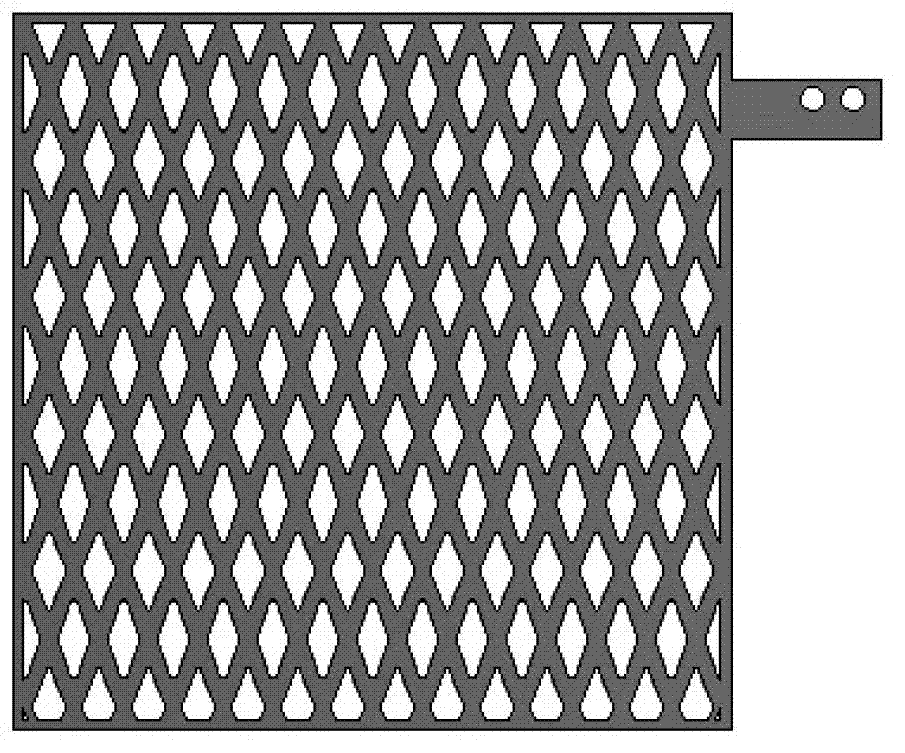

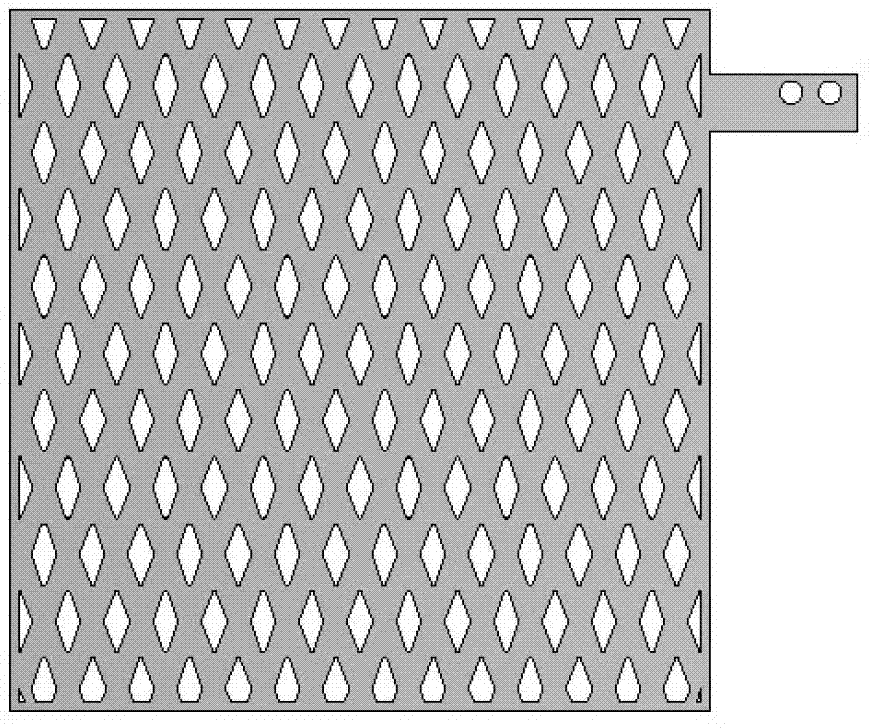

[0046] The electrolytic cell uses a titanium-based lead dioxide composite electrode plate as an anode plate and a cathode plate, and the composite electrode plates are arranged in sequence to form several cell units. The anodes and cathodes of adjacent composite electrode plates are opposite, and each interval is 7 composite electrodes The plate is provided with a baffle plate with a gap left on the cell wall of the electrolytic cell, and every two adjacent baffles are staggered with the gaps left on the cell wall of the electrolytic cell. A water inlet is provided above one end of the electrolytic cell, and There is a water outlet below the bottom, the composite electrode plate is compositely made by sandwiching an insulating plate between the titanium-based lead dioxide anode plate and the titanium plate ...

Embodiment 2

[0051] The electrolytic cell is the same as in Example 1, except that the distance between the adjacent composite electrode plates is changed to 2 cm.

[0052] The biochemical tail water of a textile printing and dyeing company, the water quality is: conductivity 14.33ms / cm, salinity 7.36g / L, ammonia nitrogen 162mg / L, pH6.8, COD 650mg / L, chroma 500. The wastewater treatment process is the same as in Example 1, and the results are shown in Table 2.

[0053] Table 2 Water quality before and after treatment of printing and dyeing wastewater

[0054]

[0055] The results in Table 1 and Table 2 show that at a current density of 15mA / cm 2 Under certain treatment conditions, the hydraulic retention time of wastewater is 1 hour, and both effluent COD and ammonia nitrogen can meet the nanotube standard. The electrocatalytic oxidation method involved in the present invention is suitable for advanced treatment of industrial wastewater biochemical effluent.

[0056] In summary, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com