Manufacturing method of negative temperature coefficient ceramic thermistor

A technology of negative temperature coefficient and thermistor, which is applied in the direction of resistors with negative temperature coefficient, etc., can solve the problems of low density, affecting material heat conduction, and low maximum DC voltage, so as to increase the maximum DC voltage and improve the thermal conductivity coefficient , Improve the effect of dissipation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

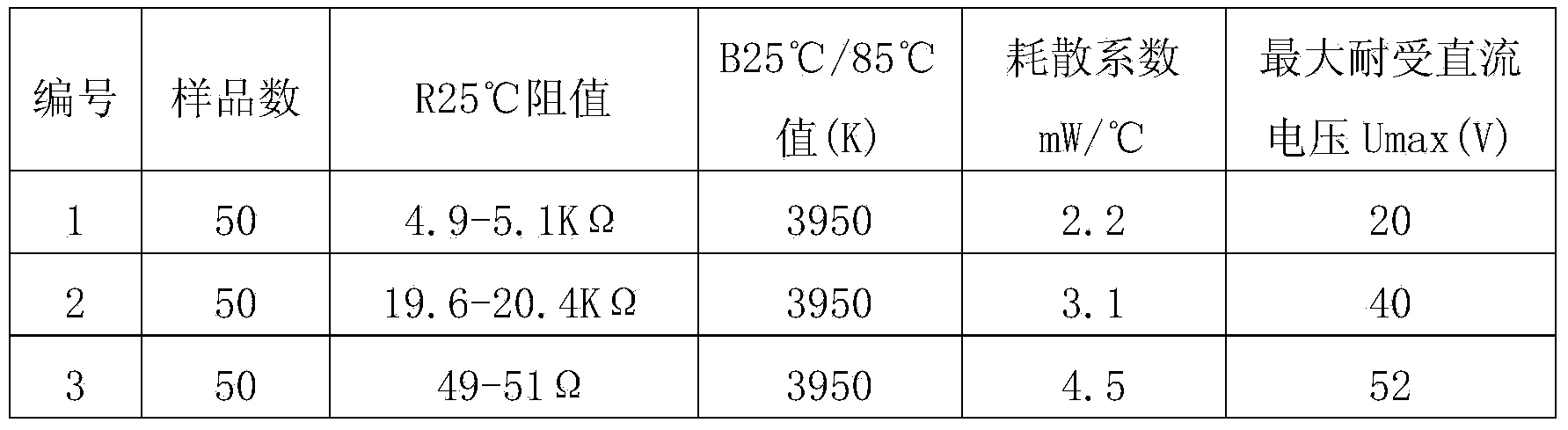

Examples

example 1

[0015] 1) Preparation of powder: analyze the pure Mn of manganese, cobalt and iron at the nanometer level 3 o 4 ,Co 3 o 4 ,Fe 2 o 3 As the main raw material, the elemental ratio of Mn, Co, and Fe in each oxide is 0.6:1.0:0.3, and a small amount of ZnO is doped, and the doping amount of ZnO is Mn 3 o 4 ,Co 3 o 4 ,Fe 2 o 3 2% of the total. Mix evenly, go through ball milling, pre-fire at 900°C for 2 hours, spray, add PVA solution to granulate, and obtain ceramic particles;

[0016] 2) Preparation of ceramic matrix: After the ceramic particles are formed by isostatic pressing at room temperature, they are placed in a hot-press furnace. While the temperature is raised from room temperature to 1050, the pressure is raised from normal pressure to 10MPa for sintering for 6 hours, and then the pressure is lowered while cooling to normal temperature and normal pressure to obtain a heat-sensitive ceramic substrate;

[0017] 3) Preparation of surface electrodes: prepare surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com