Method for extracting wedelia lactone by using microwave-assisted technology

A microwave-assisted, wedelolide-based technology, applied in the direction of organic chemistry, can solve the problems of complex production process and high synthesis cost, and achieve the effects of convenient operation, wide industrial application and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

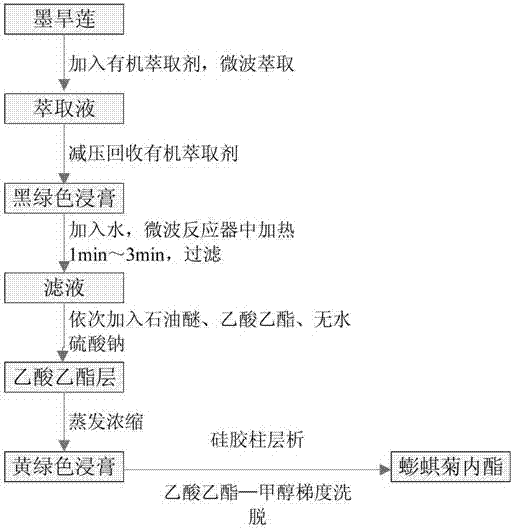

Method used

Image

Examples

Embodiment 1

[0026] Take 1 kg of Eclipta whole grass and crush it, add methanol with a volume fraction of 70%, and a solid-to-liquid ratio of 1:5, here the two are measured by kg:l (a solid-to-liquid ratio of 1:5 to 1:8 is also suitable), microwave Extract once, each extraction time is 3min, filter the extract, use a rotary evaporator to concentrate and recover methanol, and control the temperature at 45°C to obtain a black-green extract. Add 3 times the volume of black-green extract, heat in a microwave generator at 70°C for 2 minutes, and filter while hot. The filtrate is successively removed with petroleum ether to remove fat-soluble components such as chlorophyll, extracted twice with 2L ethyl acetate, anhydrous sulfuric acid Sodium dehydration, concentrated under reduced pressure to obtain a yellow-green extract, each time take the extract 1:4 on a silica gel column, the column volume is 1.5L, the diameter-to-height ratio is 1:9, and the ethyl acetate-methanol volume ratio is 20:1 Gra...

Embodiment 2

[0028] Take 1kg of Eclipta whole grass and crush it, add ethanol with a volume fraction of 75%, and the solid-to-liquid ratio is 1:10, here the two are measured by kg:l (solid-to-liquid ratio 1:9~1:13 is also suitable), microwave Extract 2 times, each extraction time is 6min, filter the extract, combine the filtrate, use a rotary evaporator to decompress and concentrate to recover methanol, and the temperature is controlled at 60°C to obtain a black-green extract. Add 2 times the volume of water of the black-green extract, heat in a microwave generator at 75°C for 3 minutes, filter while hot, remove fat-soluble components such as chlorophyll with petroleum ether in turn, extract 3 times with 1.8L ethyl acetate, anhydrous Sodium sulfate dehydration, concentrated under reduced pressure to obtain a yellow-green extract, each time take the extract 1:3 on the silica gel column, the column volume is 1.5L, the diameter-to-height ratio is 1:6, and the ethyl acetate-methanol volume rati...

Embodiment 3

[0030] Take 10kg of Eclipta whole grass and pulverize it, add methanol with a volume fraction of 75%, and the solid-to-liquid ratio is 1:16, here the two are measured by kg:l (the solid-to-liquid ratio is also suitable for 1:14 to 1:17), microwave Extract 2 times, each extraction time is 9min, filter the extract, combine the filtrates, use a rotary evaporator to decompress and concentrate to recover methanol, and control the temperature at 55°C to obtain a black-green extract. Add 3 times the volume of the black-green extract, heat in a microwave generator at 75°C for 2 minutes, and filter while it is hot. The filtrate is successively removed with petroleum ether for fat-soluble components such as chlorophyll, extracted 3 times with 16L ethyl acetate, anhydrous sulfuric acid Sodium dehydration, concentrated under reduced pressure to obtain a yellow-green extract, each time take the extract 1:5 on a silica gel column, the column volume is 15L, the diameter-to-height ratio is 1:9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com