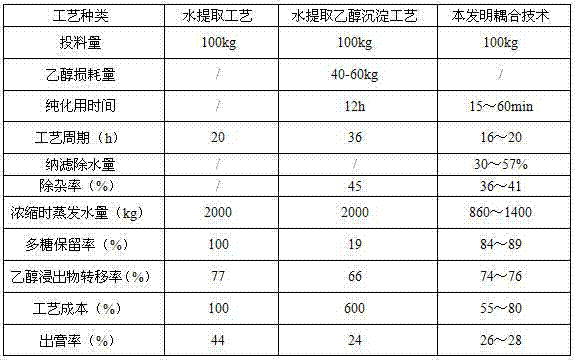

Method for preparing hedysarum polybotrys extract by adopting coupling technology

A technology of extract and red qi, which is applied in the field of plant medicine extraction and purification, can solve the problems of high impurities in the extract, high production cost, and high loss rate of active ingredients, so as to improve the quality of the extract, save the cost of recycling, and shorten the heating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 100 kg of red sage medicinal material, put it in a multifunctional extraction tank, add 1000 kg of water, and extract with reflux for 3 hours to remove the medicinal residue to obtain a water extract. The commercially available pectinase consisting of propectinase, pectin esterase, pectin hydrolase and pectin lyase was added to the water extract at a temperature of 15°C at an amount of 1000 enzyme activity units per kilogram of water extract. Stir and mix well, enzymatically hydrolyze for 120 minutes, and then settle for 3 hours to remove insoluble impurities at the bottom of the container to obtain an enzymatic hydrolysis extract. The enzymatic hydrolysis extract was subjected to the first ultrafiltration under the conditions of membrane molecular retention of 150,000 Daltons, ultrafiltration temperature of 15°C, ultrafiltration pressure of 0.5MPa, and cross-flow velocity of the material liquid on the membrane surface of 5 m / s. Obtain the first filtrate and the fir...

Embodiment 2

[0037] Take 100kg of Red Qi medicinal material, put it in a multifunctional extraction tank, add 400kg of water each time, heat and reflux for extraction 2 times, each extraction time is 2 hours, remove the medicinal residue, combine the 2 extractions to obtain the water extract; The commercially available pectinase consisting of enzyme, pectin esterase, pectin hydrolase and pectin lyase is added to the water extract at a temperature of 30°C at an amount of 80,000 units of enzyme activity per kilogram of water extract, and stir and mix well. Enzymatic hydrolysis for 80 minutes, and then settling for 4 hours to remove insoluble impurities at the bottom of the container to obtain an enzymatic hydrolysis extract. The enzymatic hydrolysis extract was subjected to the first ultrafiltration under the conditions of membrane molecular retention of 50,000 Daltons, ultrafiltration temperature of 80°C, ultrafiltration pressure of 1.0MPa, and cross-flow velocity of the material liquid on th...

Embodiment 3

[0039] Take 100kg of Hedysarum medicinal material, put it in a multifunctional extraction tank, add 600kg of water each time, heat and reflux for extraction 3 times, each extraction time is 2 hours, remove the medicinal residue, combine the 3 extractions to obtain the water extract; The commercially available pectinase consisting of enzyme, pectin esterase, pectin hydrolase and pectin lyase is added to the water extract at a temperature of 50°C at an amount of 40,500 enzyme activity units per kilogram of water extract, and stir and mix well. Enzymatic hydrolysis for 20 minutes and then settling for 3.5 hours to remove insoluble impurities at the bottom of the container to obtain an enzymatic hydrolysis extract. The enzymatic hydrolysis extract was subjected to ultrafiltration under the conditions of membrane molecular retention of 500,000 Daltons, ultrafiltration temperature of 40°C, ultrafiltration pressure of 0.1 MPa, and cross-flow velocity of the material liquid on the membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com