Method for extracting and separating proteins from cake by using ionic liquid and enzyme process

An ionic liquid and enzymatic extraction technology, applied in the field of protein separation and purification, can solve the problems of complex operation, high cost and low extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

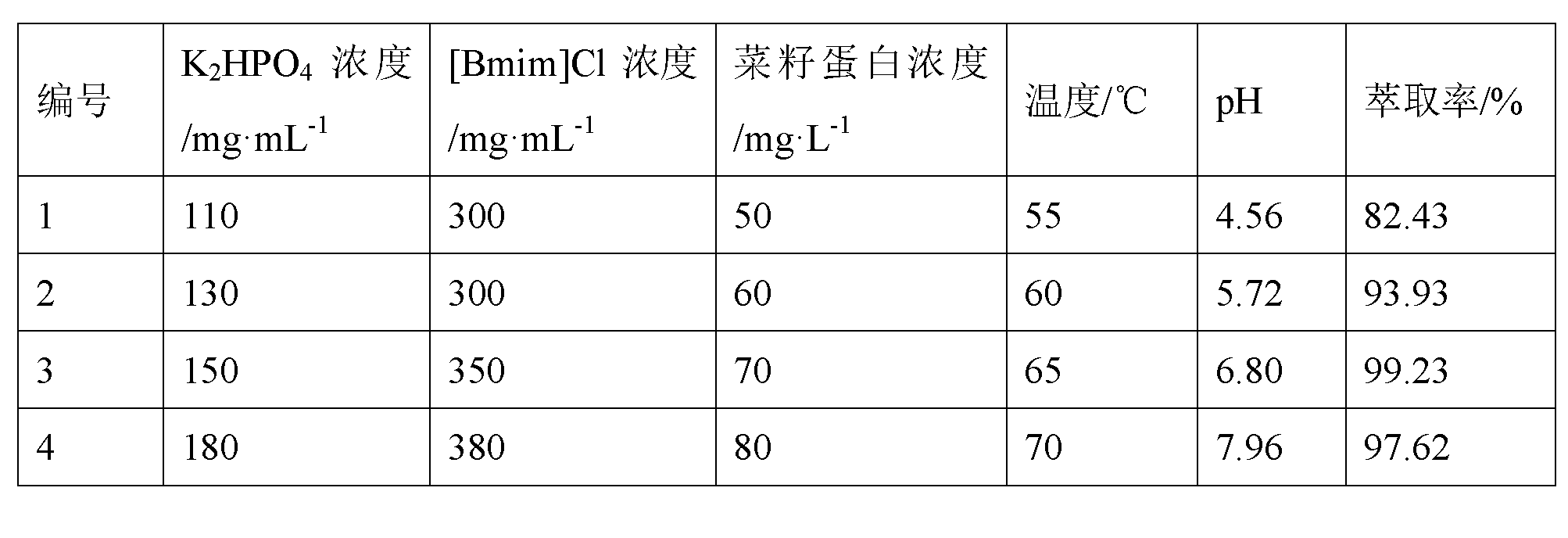

Examples

Embodiment 1

[0041] (1) Crush and sieve high-temperature rapeseed meal, degrease petroleum ether to obtain defatted rapeseed meal powder;

[0042] (2) Mix defatted rapeseed meal powder with phosphate buffer solution with pH=8.0, add α-amylase and cellulase to make a mixture, enzymatically hydrolyze the mixture at 60 °C for 4 hours, and then 4000 r min -1 Centrifuge for 20 minutes to obtain enzymatic hydrolysis solution and precipitate.

[0043] The solid-liquid mass ratio of the defatted rapeseed meal powder and the phosphate buffer is 1:15;

[0044] The enzyme activities of α-amylase and cellulase in the mixed solution were 110 U·g -1 and 60 U·g -1 , with a total enzyme activity of 170 U·g -1 .

[0045] (3) Add the precipitate from step (2) to 10 times the amount of water, and use 0.5 mol L -1 NaOH was adjusted to pH=10 for alkali dissolution reaction, after 2h, 4000 r·min -1 Centrifuge for 20min, combine the separated supernatant with the enzymolysis solution in step (2), add 0...

Embodiment 2

[0050] (1) crushing and sieving high-temperature rapeseed meal, degreasing with cyclohexane to obtain defatted rapeseed meal powder;

[0051] (2) Mix defatted rapeseed meal powder with phosphate buffer solution at pH = 8.0, add α-amylase and cellulase to make a mixture, enzymatically hydrolyze the mixture at 55 °C for 3 h, and 4000 r· min -1 Centrifuge for 20 minutes to obtain enzymatic hydrolysis solution and precipitate.

[0052] The solid-to-liquid mass ratio of the defatted rapeseed meal powder to the phosphate buffer is 1:10;

[0053] The enzyme activities of α-amylase and cellulase in the mixed solution were 90 U·g -1 and 50 U·g -1 , with a total enzyme activity of 140 U·g -1 .

[0054] (3) Add the precipitate from step (2) to 10 times the amount of water, and use 0.5 mol L -1 NaOH was adjusted to pH=10 for alkali dissolution reaction, after 2h, 4000 r·min -1 Centrifuge for 20 min, combine the separated supernatant with the enzymatic hydrolysis solution in step ...

Embodiment 3

[0059] (1) crushing and sieving low-temperature rapeseed meal, degreasing with n-hexane to obtain defatted rapeseed meal powder;

[0060] (2) Mix defatted rapeseed meal powder with boric acid buffer solution at pH=9.0, add α-amylase, cellulase and pectinase to make a mixture, and enzymolyze the mixture at 60 °C for 5 h , 4000 rpm -1 Centrifuge for 20 minutes to obtain enzymatic hydrolysis solution and precipitate.

[0061] The solid-liquid mass ratio of the defatted rapeseed meal powder and boric acid buffer solution is 1:15;

[0062] The enzyme activities of α-amylase, cellulase and pectinase in the mixed solution were 70 U·g -1 , 40 U·g -1 and 50 U·g -1 , with a total enzyme activity of 160 U·g -1 .

[0063] (3) Add the precipitate from step (2) to 10 times the amount of water, and use 0.5 mol L -1 NaOH was adjusted to pH=10 for alkali dissolution reaction, after 2h, 4000 r·min -1 Centrifuge for 20min, combine the separated supernatant with the enzymolysis solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com