Solvent-free nanometer modified epoxy weather-resistant type anticorrosive paint and preparation method thereof

A nano-modified, anti-corrosion coating technology, applied in the field of coatings, can solve problems such as reduction and loss of gloss, and achieve the effects of simple process, large film thickness, good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

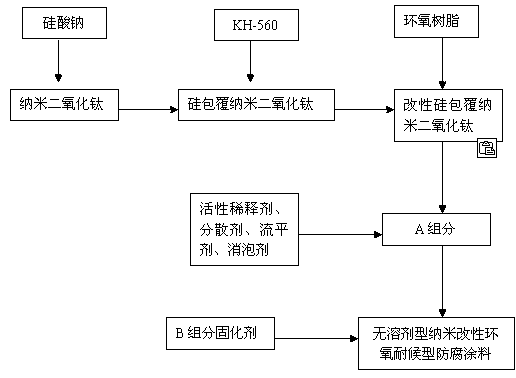

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of silicon-coated nano-titanium dioxide in component A

[0038] a Disperse 5 g of nano-titanium dioxide in 100 g of deionized water, add 0.05 g of dispersant NaOH, adjust the pH value of the solution to 10, add 0.12 g of PVP to the solution, and ultrasonically oscillate for 30 minutes to fully disperse the nano-titanium dioxide in the aqueous solution;

[0039] b In the slurry obtained in step a, slowly add a mass fraction of 1% sodium silicate aqueous solution to SiO 2 The content is 3% of the mass of nano-titanium dioxide, adjust the pH value of the solution to 9, keep the temperature at 80°C, and stir at a low speed for 2 hours;

[0040] c The solution obtained in step b was aged at 60°C for 2h, then dried, and calcined at 800°C for 2h to obtain silicon-coated nano-titanium dioxide.

[0041] (2) Preparation of solvent-free nano-modified epoxy weather-resistant anti-corrosion coating

[0042] A weighs 3g of silicon-coated nano-titanium dioxide disper...

example 2

[0050] (1) Preparation of silicon-coated nano-titanium dioxide in component A

[0051] a Weigh 5g of nano-titanium dioxide and disperse it in 100ml of deionized water, add 0.1g of dispersant sodium silicate, adjust the pH value of the solution to 10, add 0.12g of PVP to the solution, and oscillate ultrasonically for 30min to fully disperse;

[0052] b In the slurry obtained in step a, slowly add a mass fraction of 1% sodium silicate aqueous solution to SiO 2 The content is 1% of the mass of nano-titanium dioxide, adjust the pH value of the solution to 9, keep the temperature at 80°C, and stir at a low speed for 2 hours;

[0053] c. Aging the solution obtained in step b at 60° C. for 2 hours, then drying, and calcining at 800° C. for 2 hours to obtain silicon-coated nano-titanium dioxide.

[0054] (2) Preparation of solvent-free nano-modified epoxy weather-resistant anti-corrosion coating

[0055] A weighs 3g of silicon-coated nano-titanium dioxide dispersed in 100ml ethanol ...

example 3

[0063] (1) Preparation of silicon-coated nano-titanium dioxide in component A

[0064] a Weigh 5g of nano-titanium dioxide and disperse it in 100ml of deionized water, add 0.1g of dispersant metasodium hexaphosphate, adjust the pH value of the solution to 10, add 0.12g of PVP to the solution, and ultrasonically oscillate for 30 minutes to make it fully dispersed;

[0065] b In the slurry obtained in step a, slowly add a mass fraction of 1% sodium silicate aqueous solution to SiO 2 The content is 1% of the mass of nano-titanium dioxide, adjust the pH value of the solution to 9, keep the temperature at 80°C, and stir at a low speed for 2 hours;

[0066] c. Aging the solution obtained in step b at 60° C. for 2 hours, then drying, and calcining at 800° C. for 2 hours to obtain silicon-coated nano-titanium dioxide.

[0067] (2) Preparation of solvent-free nano-modified epoxy weather-resistant anti-corrosion coating

[0068] A weighs 3g of silicon-coated nano-titanium dioxide disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

| Hard work time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com