Radio frequency device and manufacturing method thereof

A technology of a radio frequency device and a manufacturing method, applied in the field of microelectronics, can solve the problems of reducing the control ability of the gate to the channel, reducing the concentration of two-dimensional electron gas, and reducing the radio frequency performance of the device, so as to reduce the stress release and improve the radio frequency performance. , the effect of reducing the surface density of states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

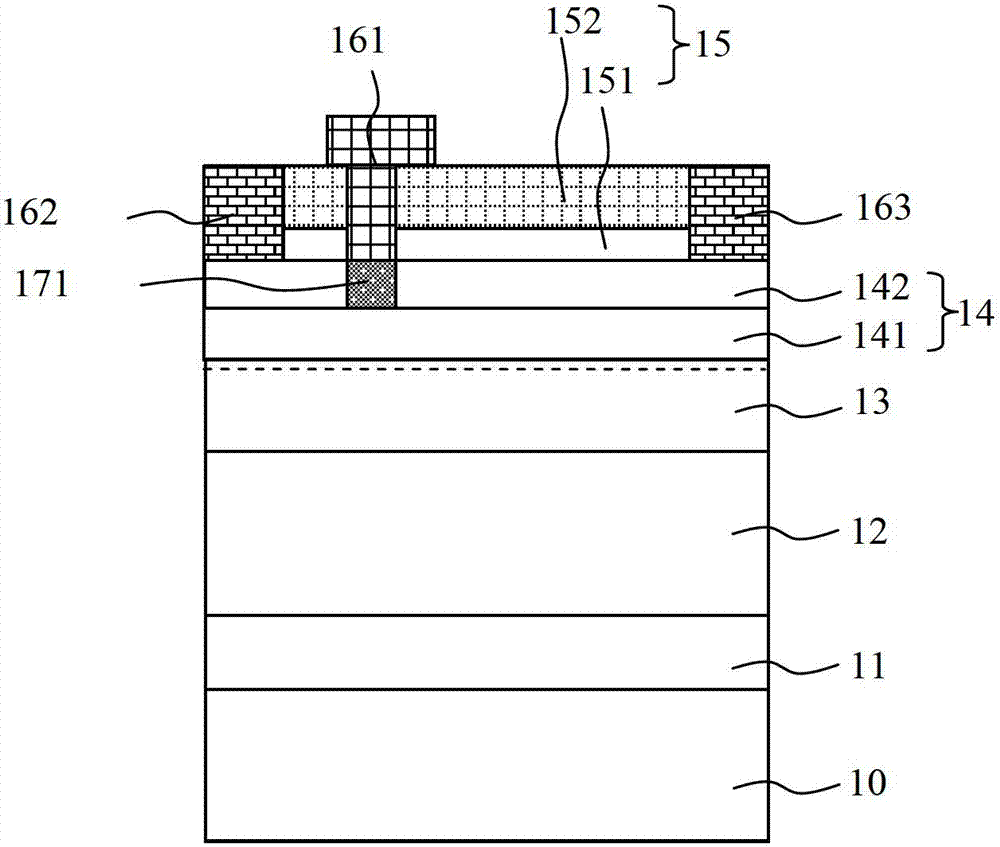

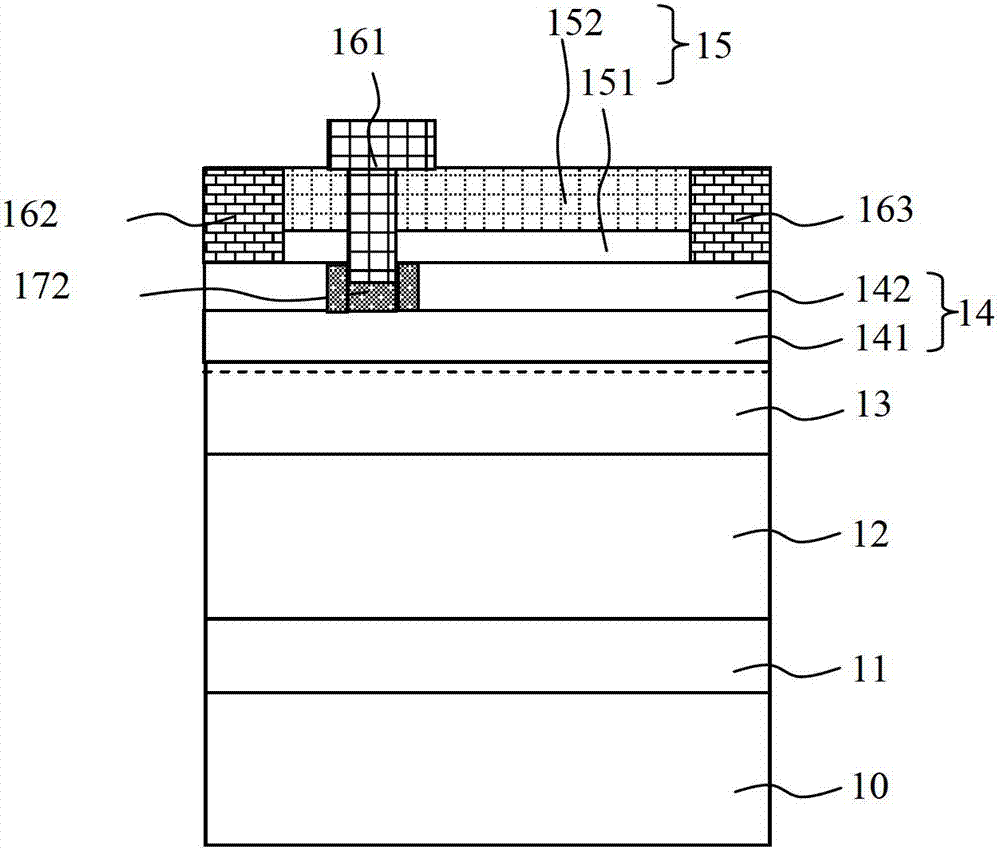

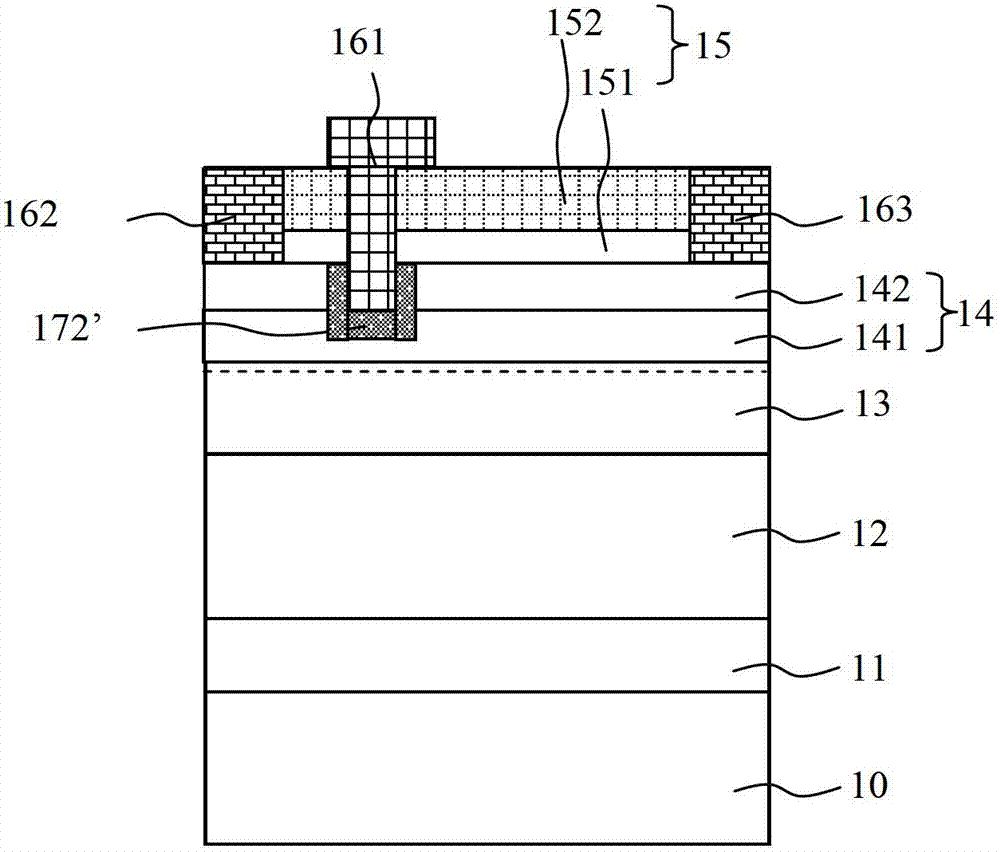

[0050] As mentioned in the background art, the application of aluminum nitride in gallium nitride-based high electron mobility transistors greatly improves the radio frequency performance of the device. However, the wide energy band width makes the aluminum nitride material produce a high Schottky barrier when it is in contact with the metal material, which greatly improves the contact resistance of the drain and source. At the same time, in order to adjust the lattice mismatch between aluminum nitride and gallium nitride, the existing technology often introduces a gallium nitride capping layer on the surface of aluminum nitride, and the gallium nitride capping layer increases the gate to the two-dimensional electron Air distance, thereby degrading the RF performance of the device.

[0051] In order to improve the above two disadvantages and improve the radio frequency performance of GaN-based high electron mobility transistors, the present invention proposes a radio frequency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com