Polyaniline/attapulgite nano-material antirust primer and preparation method thereof

A nano-material and anti-rust primer technology, applied in the field of coatings, can solve the problems of low price, heavy odor, environmental protection and personnel hazards, and achieve the effect of improving anti-rust effect, low odor and improving anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

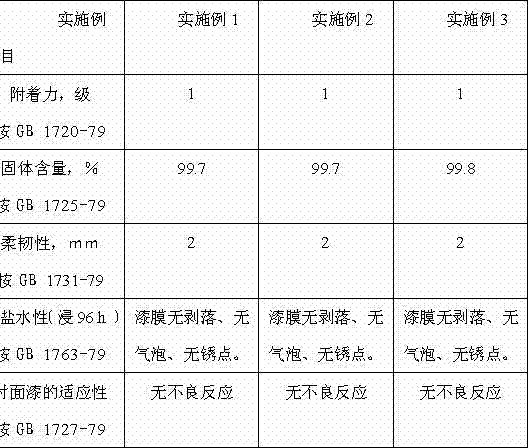

Examples

Embodiment 1

[0040] (1) Preparation of component A:

[0041] ①. Weigh each component according to parts by weight;

[0042] ②. Add 47 parts of NC-541 cardanol-modified amine epoxy curing agent from Cardolite Company of the United States into the paint mixing tank, and stir at a speed of 1800 r / min at room temperature. Add 3 parts of R-1541 modified epoxy resin from Kunshan) Co., Ltd. into the paint mixing tank. After the addition is complete, continue to stir at 900 r / min at room temperature for 1 hour, then store for 15 hours and wait for use;

[0043] ③. On the basis of step ②, continue to add 3 parts of polyaniline / attapulgite nanomaterials, 9 parts of pigments (the weight ratio of 800 mesh zinc phosphate to 1000 mesh mica iron oxide is 1:1), and 7 parts of 1250 mesh precipitated barium sulfate and 0.3 parts of TYZOR GBA titanate chelate from DuPont Company of the United States were added to the paint mixing tank in turn. At room temperature, the materials in the paint mixing tank were...

Embodiment 2

[0047] (1) Preparation of component A:

[0048] ①. Weigh each component according to parts by weight;

[0049] ② Add 62 parts of D9340 epoxy curing agent from Shanghai Junjiang Technology Co., Ltd. Add 8 parts of 1348 modified epoxy resin into the paint mixing tank. After the addition is completed, continue to stir at a speed of 1000 r / min at room temperature for 1.5 hours, then store for 13 hours and wait for use;

[0050] ③. On the basis of step ②, continue to add 10 parts of polyaniline / attapulgite nanomaterials, 18 parts of pigments (the weight ratio of 1250 mesh aluminum tripolyphosphate to 1000 mesh mica iron oxide is 1:1.5), 1250 mesh silica powder 10 1 part and 0.6 parts of TYZOR AA-75 titanate chelate from DuPont Company of the United States were successively added to the paint mixing tank. 16 parts of LITE-2023 multifunctional resin modifier to adjust the viscosity of the slurry, continue to stir for 10 minutes, use a paint knife to stir up the slurry to fall freel...

Embodiment 3

[0054] (1) Preparation of component A:

[0055] ①. Weigh each component according to parts by weight;

[0056] ②. Put 47 parts of NC-541 cardanol-modified amine epoxy curing agent from American Cardolite company into the paint mixing tank, stir at 2000 r / min at room temperature, and slowly mix Xuya Electronic Chemicals ( Add 8 parts of R-1348 isocyanate-modified epoxy resin from Kunshan) Co., Ltd. into the paint mixing tank. After the addition is completed, continue to stir at 800 r / min at room temperature for 1.2 hours, then store for 11 hours and wait for use;

[0057] ③. On the basis of step ②, continue to add 5 parts of polyaniline / attapulgite nanomaterials, 13 parts of pigments (the weight ratio of 800 mesh zinc phosphate to 1250 mesh aluminum tripolyphosphate is 0.5:1), 1250 mesh precipitated barium sulfate 5 0.8 parts, 0.8 parts of TYZOR GBA titanate chelate compound of DuPont Company of the United States were added to the paint mixing tank in sequence. Adjust the vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com