Magnetic stabilization catalytic reforming device and method

A catalytic reforming and reforming device technology, applied in chemical instruments and methods, separation methods, catalytic conversion gas purification of impurities, etc., can solve problems such as difficult maintenance, difficult catalyst loading, uneven loading, etc., to prolong life, Environmentally friendly and controllable distribution density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

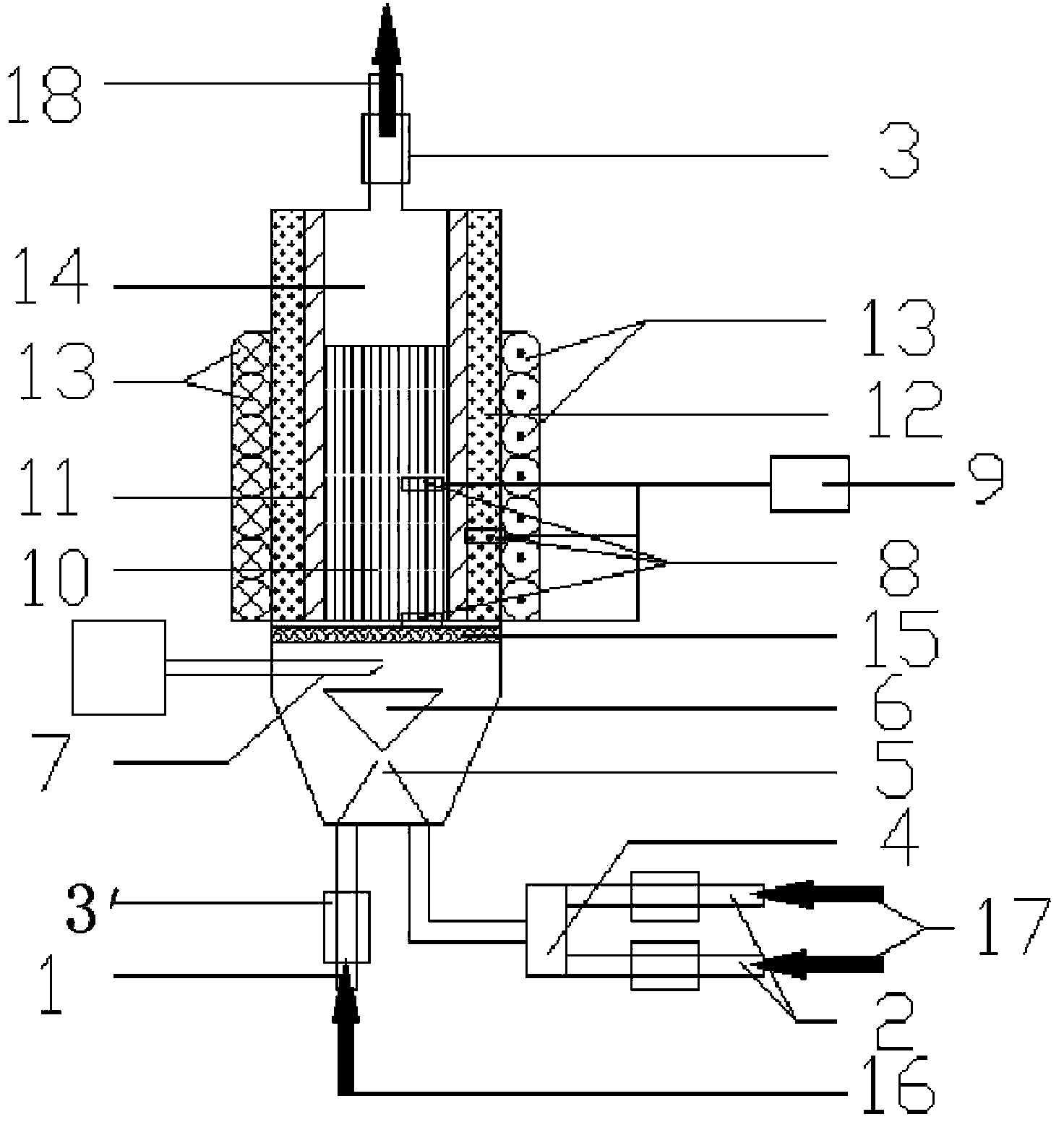

[0029] The reforming device is placed vertically, and the end of the device is connected to the gas detection equipment; the outermost layer is the coil 13, the middle layer of the reforming device is the insulation layer 12, and the inner layer is the heating resistance wire 11 wrapped by insulating ceramic; The coils of the layer are not completely wrapped, and a section of the upper part without coil wrapping forms a buffer cavity;

[0030] The material medium mixing unit is mainly composed of the feed port, the pressure flow meter 3 of the feed port, the reforming medium inlet, the pressure flow meter 3'of the medium inlet, the gas mixer 4 and the nozzle 5; the feed port 1 passes through the feed port The pressure flow meter 3 is connected to one of the air inlets of the nozzle 5; the gas mixer 4 is set at one end of the reforming medium inlet. After the reforming medium inlet 2 passes through the pressure flow meter 3'of the medium inlet, the gas mixer 4 will The different m...

Embodiment 2

[0034] The flow rate that can balance the gravity and magnetic force of the magnetic medium catalyst is defined as the critical flow rate, and the intake flow rate should be slightly greater than the critical flow rate, so that the magnetic medium generates a slight disturbance when the fuel gas passes through, leaving a section without coils on the upper part of the device The part occupies about 1 / 4 of the total length, so that the magnetic medium with a certain speed can be buffered and accelerated by gravity in this area and return to the magnetic field area. Such reciprocation achieves sufficient contact between the catalyst and the gas to be reformed, and the reaction is more complete. So as to achieve the purpose of the conversion of the gas to be reformed and the gas containing tar, the removal of tar coke, and the increase of the heating value of the fuel gas.

Embodiment 3

[0036] The preparation steps of the magnetic medium catalyst in this embodiment are:

[0037] On the surface of irregular iron, cobalt, nickel, iron oxide, iron-silicon alloy, ferrite, neodymium-iron-boron, and alnico magnetic medium with a particle size of about 0.01-0.5mm in the shape of gravel, press by impregnation, calcination, etc. A certain proportion of load such as TiO 2 , NiO, CaO, CeO, Pt and other active materials.

[0038] Specific steps: immerse the magnetic medium particles in a 10-30% concentration of metal salt solution of different components by the dipping method, mainly including: Ni(NO 3 ) 2 , Fe(NO 3 ) 3 , Mg(NO 3 ) 2 , Cu(NO 3 ) 2 . Dry at 105-120℃, then calcinate in a muffle furnace at 300-1000℃ for 1-2 hours, and then reduce with 99% hydrogen at 300℃ to prepare different feed materials The specific magnetic medium catalyst realizes the modification of the catalytic performance of the magnetic medium without affecting its magnetic properties, making a parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com