Titanium-based titanium oxide plate and manufacturing method thereof

A titanium oxide and titanium-based technology, which is applied in the field of titanium-based titanium oxide plates and their manufacture, can solve problems such as no direct growth or coverage, no mention of thin film preparation methods, and increased resistivity, so as to reduce The weight of the battery, the simple manufacturing process, and the effect of improving the energy density of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

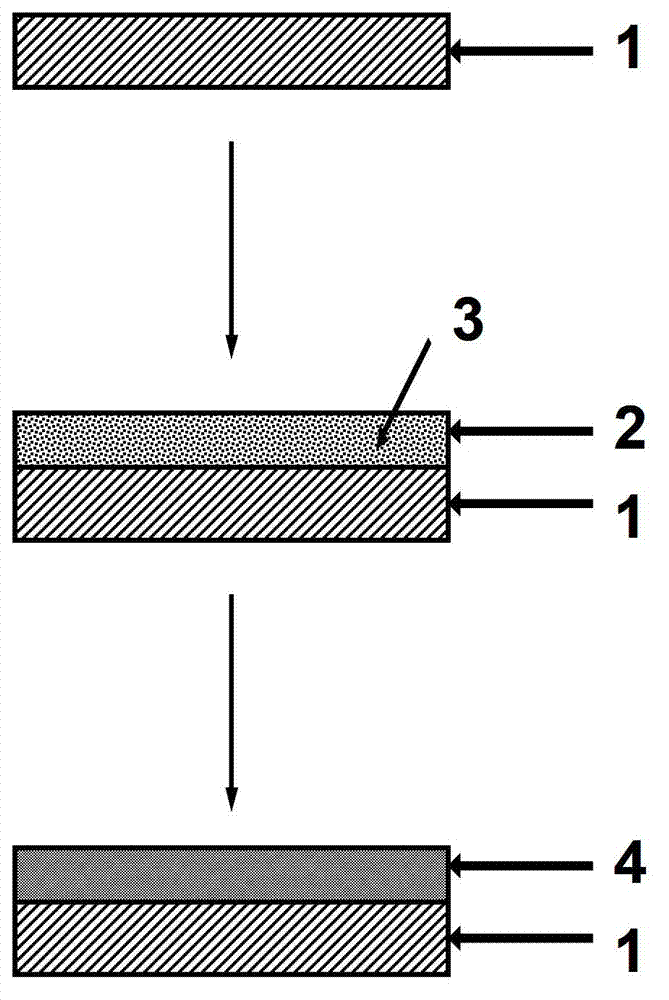

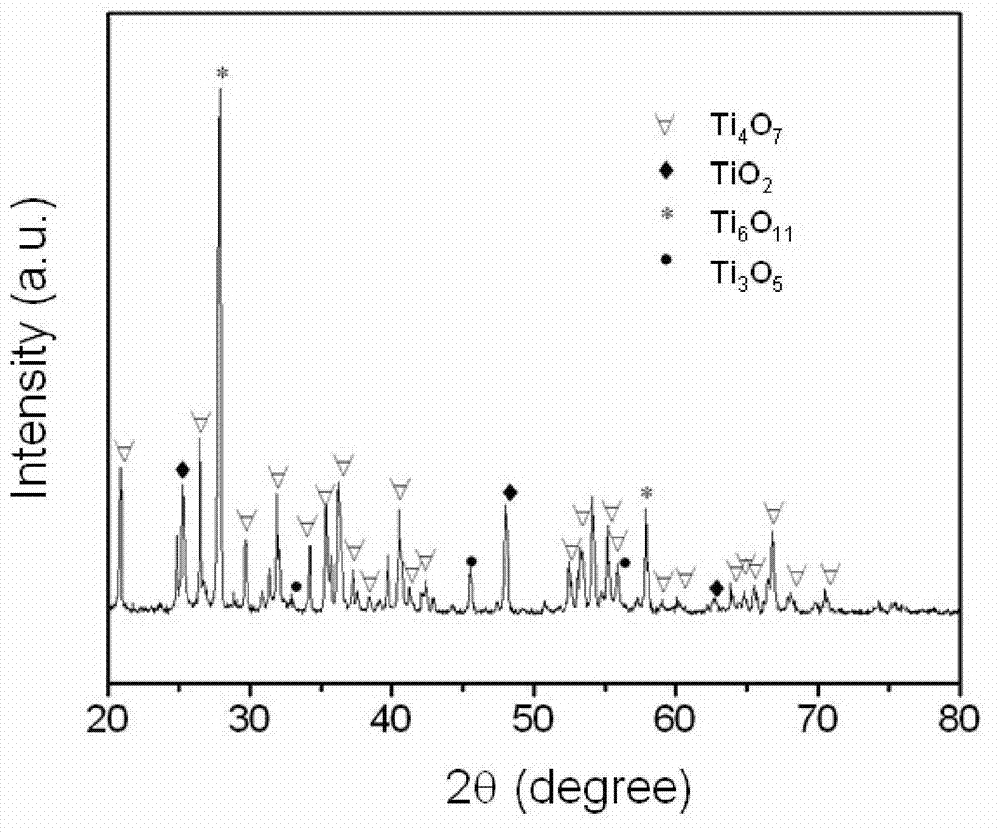

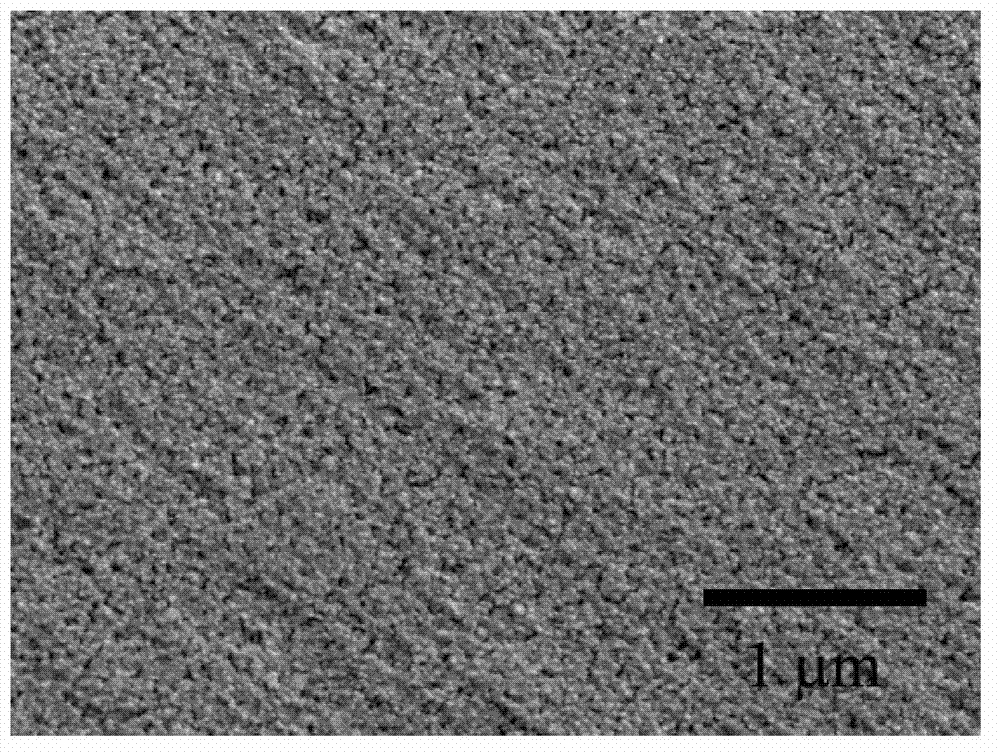

[0022] Embodiment 1: refer to figure 1 , 2 、3

[0023] (1) Degrease the industrially pure titanium plate, in HF and HNO 3 pickling in the mixed solution for 5 minutes to obtain a titanium substrate 1 with a clean surface;

[0024] (2), configure Ti(OH) 4 Sol: 20ml ethanol, 0.5ml deionized water, 0.5ml hydrochloric acid, 0.02g titanium nanopowder (D 50 40nm), 2ml tetrabutyl titanate, 0.2ml sol stabilizer;

[0025] (3) Precursor film 2 was prepared on the cleaned titanium substrate by immersion-pulling method: the titanium substrate was placed on Ti(OH) 4 Stand in the sol for 2 minutes, pull at a constant speed of 100mm / min, and set the temperature of the puller to 40 o C, repeating the above steps 10 times, each coating interval is 3min; reference number 3 is Ti nanoparticles.

[0026] (4), the precursor thin film 2 is carried out segmental heat treatment: 120 o C for 1 hour, and then 5 o C / min heating rate increased to 1300 o C, keep warm for 1 hour, cool with the...

Embodiment 2

[0029] (1) Degrease the industrial pure titanium plate, in HF and HNO 3 Pickling in the mixed solution for 5 minutes to obtain a titanium substrate with a clean surface;

[0030] (2) Configure Ti(OH) 4 Sol: 20ml ethanol, 0.5ml deionized water, 0.5ml hydrochloric acid, 0.01g titanium nanopowder (D 50 20nm), 2ml tetrabutyl titanate, 0.2ml sol stabilizer;

[0031] (3) Precursor films were prepared on the cleaned titanium substrates by immersion-lifting method: the titanium substrates were placed on Ti(OH) 4 Stand in the sol for 2 minutes, pull at a constant speed of 100mm / min, and set the temperature of the puller to 40 oC, repeat the above steps 10 times, each coating interval is 3min;

[0032] (4) Subsection heat treatment of the precursor film: 120 o C for 1 hour; then 5 o C / min heating rate up to 1000 o C, keep warm for 1 hour, cool with the furnace, heat treatment atmosphere is argon-hydrogen mixture, and the hydrogen content is 5%.

Embodiment 3

[0034] (1) Degrease the industrial pure titanium plate, in HF and HNO 3 Pickling in the mixed solution for 5 minutes to obtain a titanium substrate with a clean surface;

[0035] (2) Configure Ti(OH) 4 Sol: 20ml ethanol, 0.5ml deionized water, 0.5ml hydrochloric acid, 0.02g titanium nanopowder (D 50 40nm), 2ml tetrabutyl titanate, 0.2ml sol stabilizer;

[0036] (3) Precursor films were prepared on the cleaned titanium substrate by spin coating: the spin speed was 2500r / min, the spin coating time was 30 s, and at 40 o After C drying, repeat the above steps 10 times;

[0037] (4) Subsection heat treatment of the precursor film: 120 o C for 1 hour, and then 5 o C / min heating rate increased to 1300 o C, keep warm for 1 hour, cool with the furnace, and the heat treatment atmosphere is argon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com