Mesoporous hexaaluminate nickel supported methanation catalyst and preparation method thereof

A methanation catalyst, mesoporous hexaaluminate technology, applied in the field of methanation catalysis, can solve the problems of narrow catalyst activity temperature range, complex catalyst preparation process, catalyst carbon deposition and deactivation, etc., to achieve high activity and catalytic efficiency, The effect of low loading and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

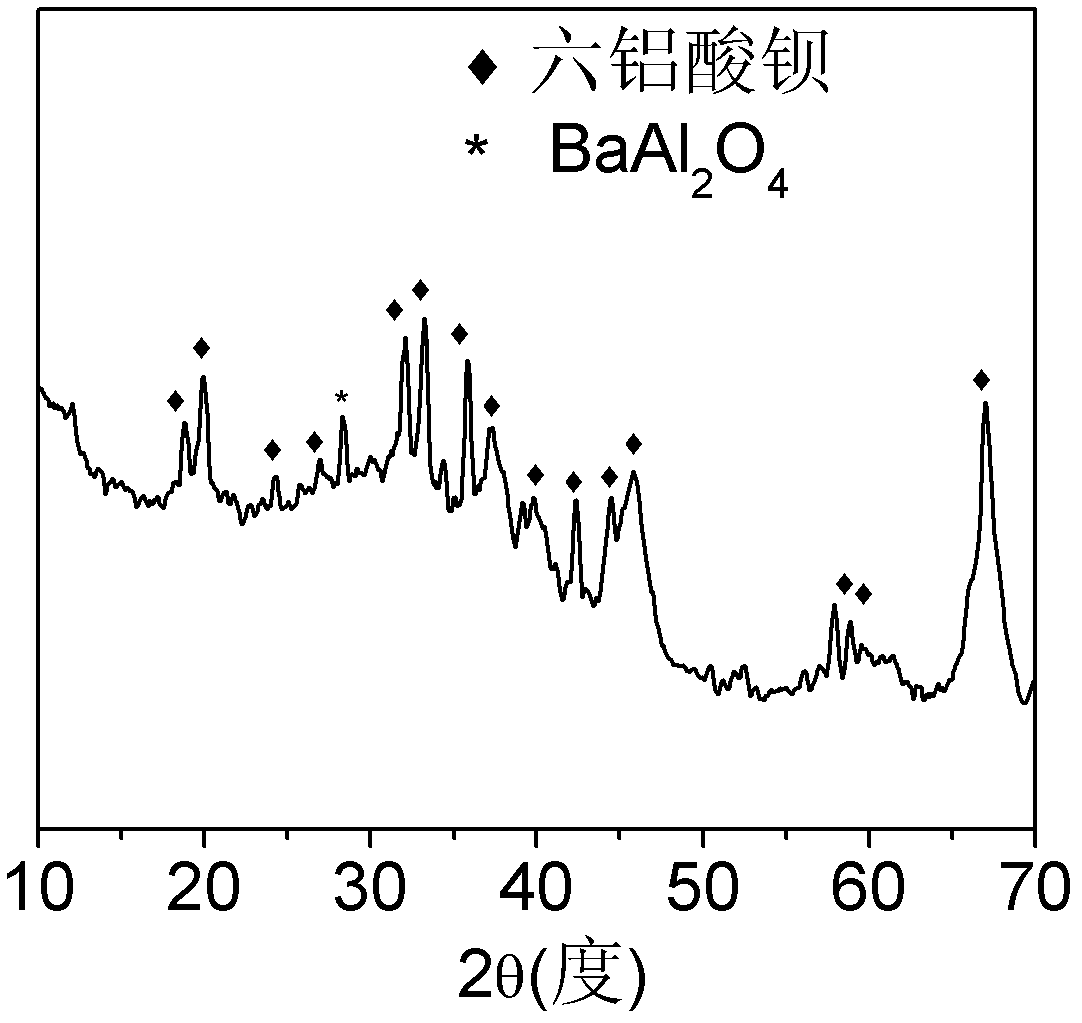

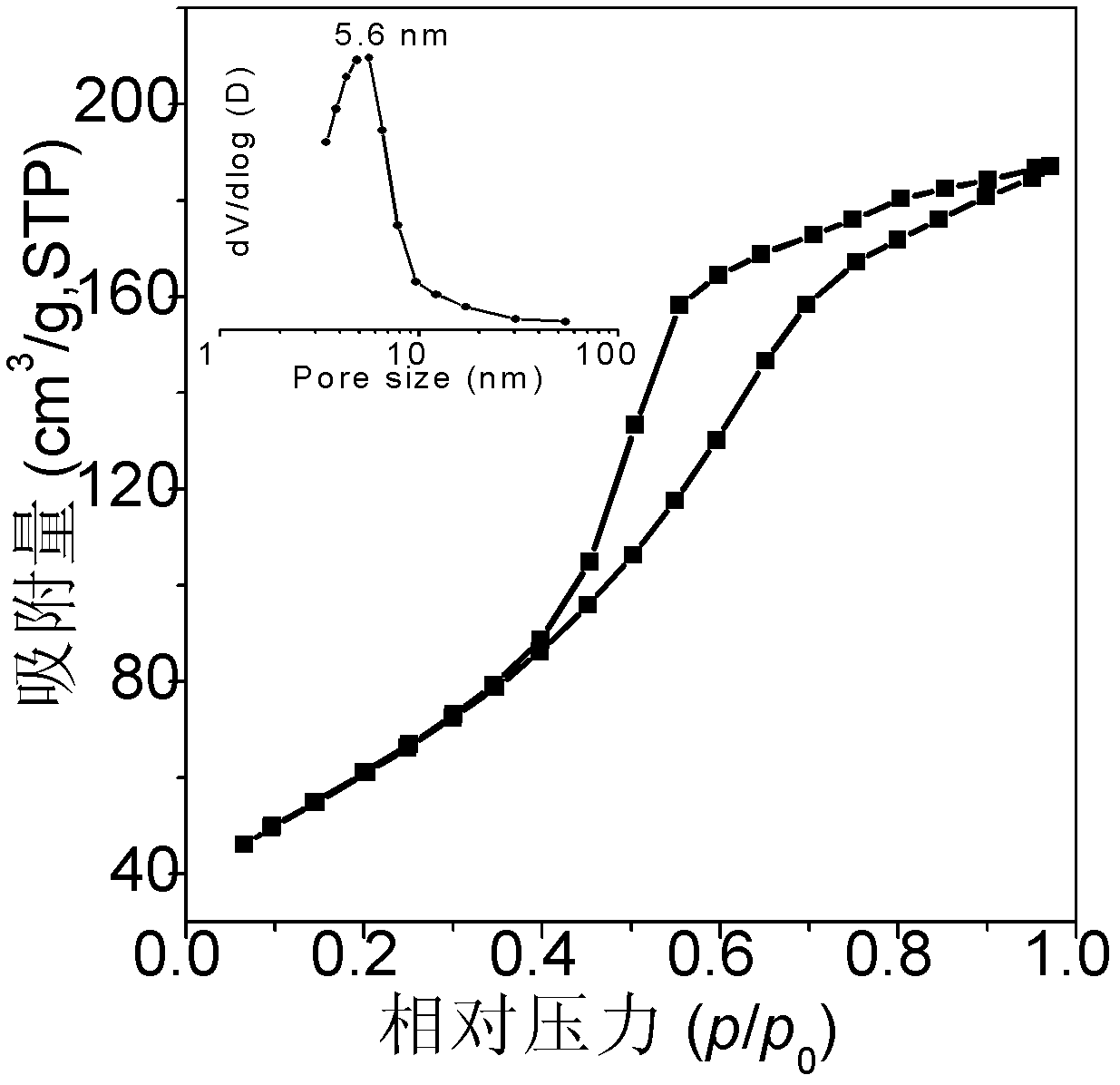

[0054] 1. Preparation of mesoporous barium hexaaluminate:

[0055] 1.0g of the prepared mesoporous carbon (the mesoporous carbon is prepared by the method in the document J.Am.Chem.Soc.2006, 128, 11652. The obtained mesoporous carbon has a pore wall thickness of 6.0nm and a mesoporous size of 6.2nm) Immerse in 15 mL of nitric acid with a concentration of 5.0 mol / L, wherein the mass ratio of carbon material to solvent is 1:15, treat at 40 ° C for 3 h, filter, wash and dry to obtain functionalized mesoporous carbon, and then highly disperse it in In 10mL ethanol, obtain suspension A; Take by weighing 4.5g aluminum nitrate, 0.26g barium nitrate and be dissolved in the mixed solution of 20mL water and ethanol (water / ethanol volume ratio is 1: 3), the salt precursor and solvent The mass ratio is 1:4.2, and the salt precursor solution B is prepared; then solution B is added to A, and the resulting mixture is stirred at 20°C and evaporated to dryness to obtain a salt / carbon composite...

Embodiment 2

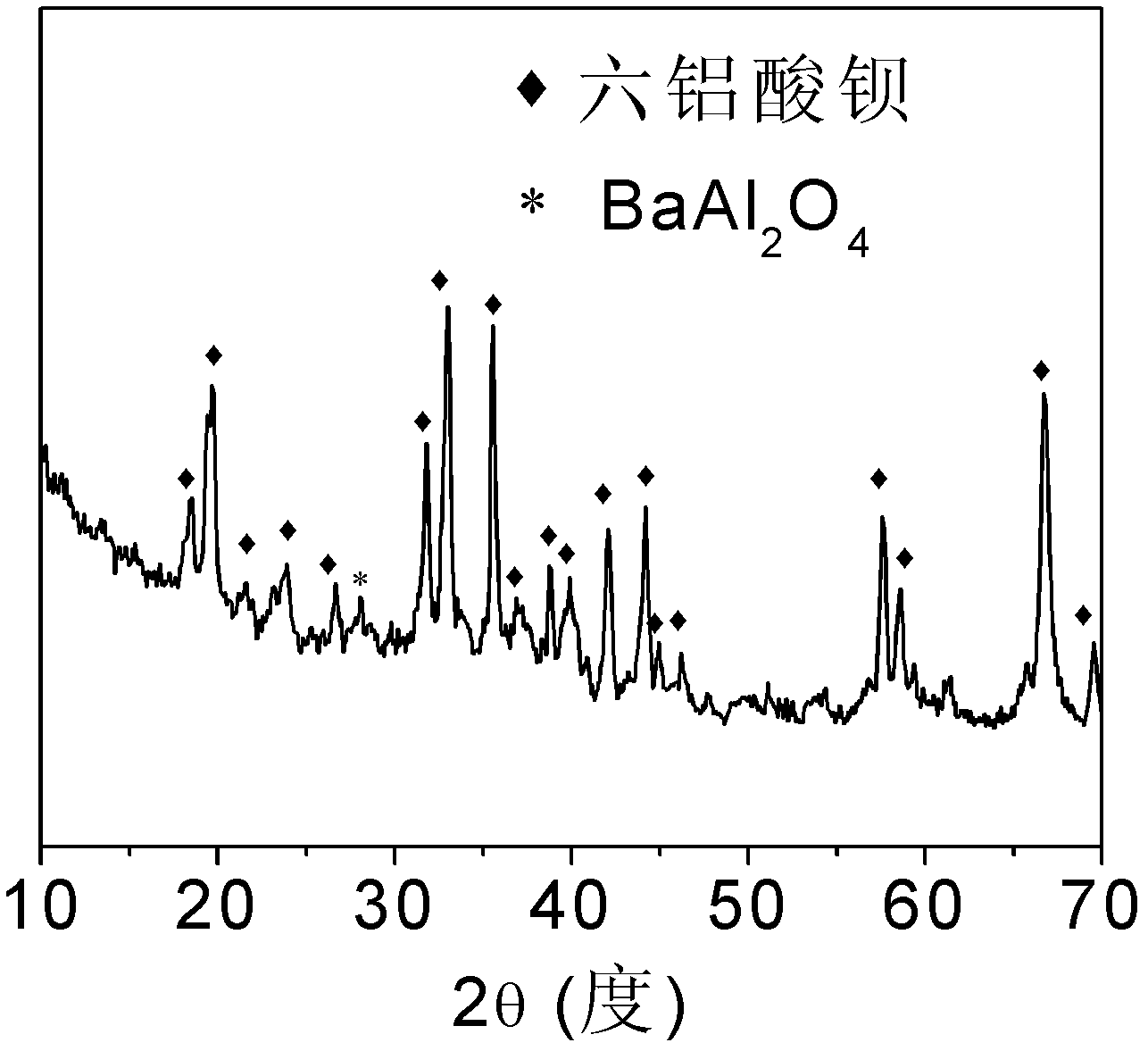

[0067] 1. Preparation of mesoporous barium hexaaluminate:

[0068] Preparation of mesoporous barium hexaaluminate: immerse 1.0 g of prepared mesoporous carbon (pore wall thickness 9.4 nm, mesopore size 7.0 nm) in 10 mL of hypochlorous acid solution with a concentration of 2.0 mol / L, wherein the carbon material and The mass ratio of the solvent is 1:10, treated at 40°C for 8 hours, filtered, washed and dried to obtain functionalized mesoporous carbon, and then highly dispersed in 10mL of ethanol to obtain suspension A; weigh 4.5g of aluminum nitrate , 0.25g barium acetate is dissolved in the mixed solution of 38mL water and acetone (water / acetone volume ratio is 3: 1), the mass ratio of salt precursor and solvent is 1: 8, makes salt precursor solution B; Then Add solution B to A, stir the resulting mixture at 40°C, and evaporate to dryness to obtain a salt / charcoal compound; put the salt / charcoal compound into a sand core funnel, place it in a 20mL container with a concentratio...

Embodiment 3

[0075] 1. Preparation of mesoporous barium hexaaluminate:

[0076] Immerse 1.0 g of the prepared mesoporous carbon (pore wall thickness 8.0 nm, mesopore size 6.5 nm) in 5 mL of 8.0 mol / L sulfuric acid, wherein the mass ratio of carbon material to solvent is 1:5, and treat at 90 ° C After 5h, filter, wash and dry to obtain functionalized mesoporous carbon, then highly disperse it in 10mL ethanol to obtain suspension A; weigh 13.5g aluminum nitrate, 0.75g barium acetate and dissolve in 28.5mL water and propanol In the mixed solution (water / propanol volume ratio is 1:1), the mass ratio of the salt precursor to the solvent is 1:2, and the salt precursor solution B is obtained; then solution B is added to A, and the resulting mixed solution Stir at 50°C and evaporate to dryness to obtain the salt / charcoal composite; put the salt / carbon composite into a sand core funnel, place it in a hydrothermal kettle with 20mL of 2.0mol / L urea aqueous solution, and place it at 110 After standin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com