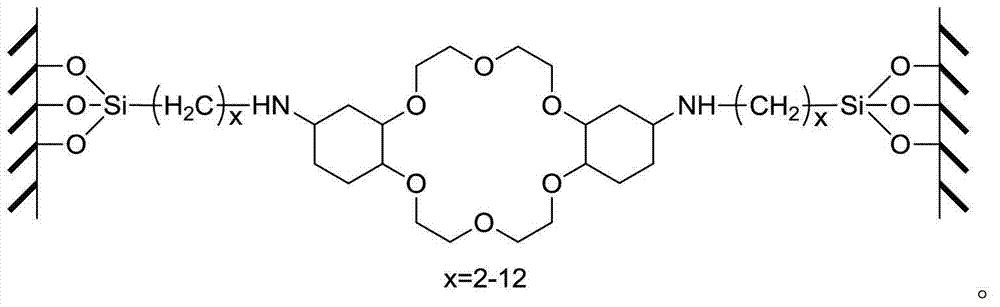

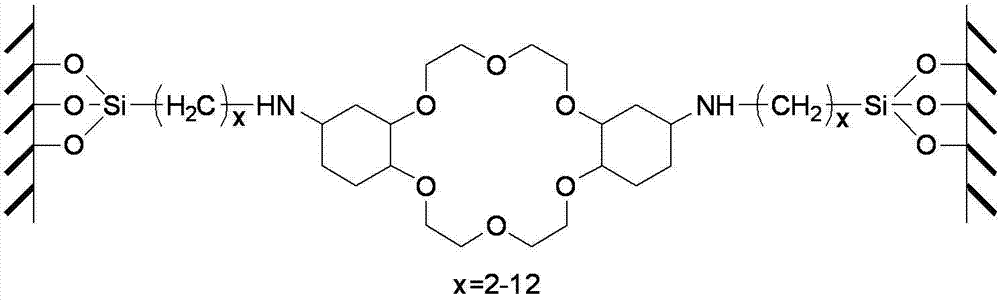

Method for separating palladium from waste water by double-arm bonding-type alicyclic crownether silicon resin

A silicone resin and cycloaliphatic technology, which is applied in the field of selective adsorption and separation of precious metal palladium, can solve the problems of high processing cost, low separation efficiency, and high technical difficulty, and achieve the effect of fast separation speed, high separation efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the enrichment of palladium ion in single palladium-containing solution

[0019] Take 5 mL of a single feed solution containing metal palladium ions (the concentration of palladium ions is 500 ppm, a neutral aqueous solution without nitric acid) in a glass test tube with a stopper, and add 0.6 g; Place the test tube on a constant temperature shaker at 28°C, shake for 50 minutes, and use a microporous membrane to separate the two-arm bonded alicyclic crown ether silicone resin and the feed solution containing metal palladium ions; Spectrometer (ICP-AES) was used to measure the remaining concentration of palladium ions in the water phase, and the calculated removal rate of palladium was 98.6%; the separated double-arm bonded alicyclic crown ether silicone resin was washed with 0.2 mol / L nitric acid solution The adsorbed palladium ions are removed, washed repeatedly with deionized water three times, and dried in an oven to obtain a regenerated double-arm bond...

Embodiment 2

[0020] Embodiment 2: the recovery of palladium in palladium, nickel electroplating rinsing waste water

[0021] Measure 20 mL of electroplating rinsing wastewater into a glass container with a stopper; the wastewater contains 7 ppm of palladium, 10 ppm of nickel, and impurities such as complexing agent ammonia; weigh 0.8 g was added to the above solution; the whole device was placed in a constant temperature shaker at 23°C and shaken for 50 minutes, and filtered through a microporous membrane to separate the double-arm bonded alicyclic crown ether silicone resin and electroplating wastewater; through inductive coupling Plasma emission spectrometer (ICP-AES) measured the remaining concentration of palladium ions in the water phase, and the removal rate of palladium ions was calculated to be 95.9%; the recovered double-arm bonded alicyclic crown ether silicone resin was used with 0.04 mol / L Elution with nitric acid solution to remove the adsorbed palladium ions, then repeated wa...

Embodiment 3

[0022] Example 3: Recovery of palladium in simulated high-level radioactive waste liquid of power pile

[0023] The simulated power pile high-level radioactive waste liquid is prepared according to the theoretical calculation value, containing 14 elements such as Ba, Cd, Fe, Mo, Na, Nd, Ni, Pd, Rb, Ru, Sr, Zr, Cs, Cr; the prepared solution After proper pretreatment, the concentration of palladium ions in it is 50 ppm; measure 10 mL of the above simulated feed solution into a stoppered glass test tube, add 0.1 g of double-arm bonded alicyclic crown ether silicone resin; place the test tube at 25 °C In a constant temperature water bath, after electromagnetic stirring for 40 min, a microporous filter membrane was used to separate the two-arm bonded alicyclic crown ether silicone resin and the metal simulated liquid; the remaining concentration of palladium ions in the liquid phase was measured by ICP-AES, and calculated The removal rate of the obtained palladium ion was 96.4%; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com