Carbon-nano-tube-reinforced polyethylene tube

A technology of carbon nanotubes and polyethylene tubes, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of poor dispersion, difficult stability, and poor bonding of carbon nanotubes, and achieve good durability and mechanical strength Improved strength and heat aging properties, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

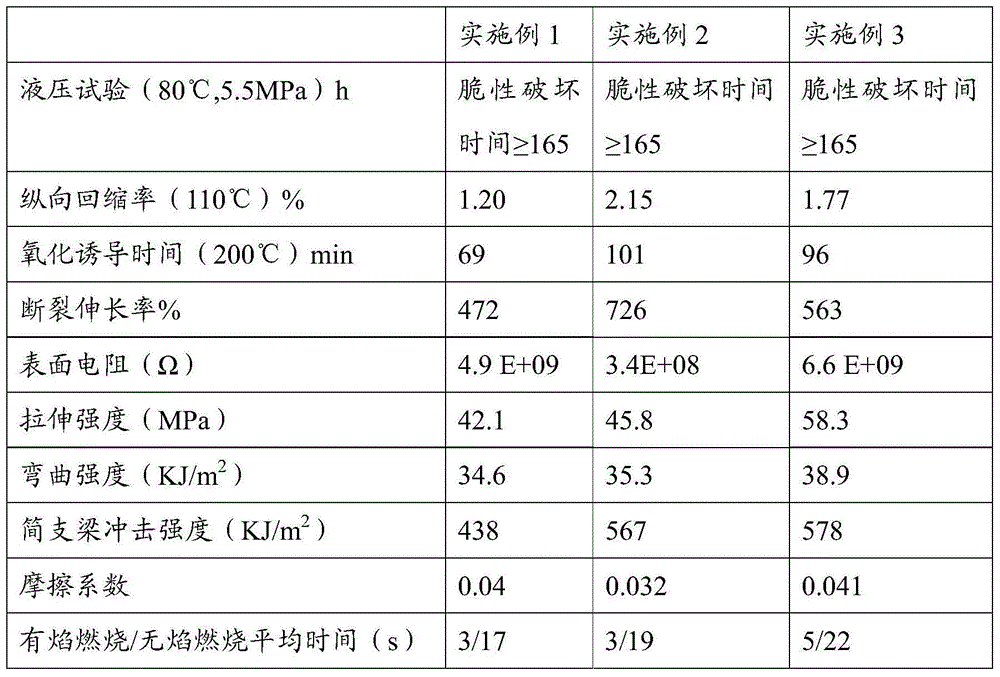

Examples

Embodiment 1

[0030] Raw materials are prepared according to the following parts by weight: 80 parts of high-density polyethylene; 2 parts of carbon nanotubes; 3 parts of lubricant, 2 parts of antistatic agent, and 5 parts of flame retardant; wherein, the lubricant is stearic acid, paraffin or polystyrene Ethylene wax; the flame retardant is a mixture of magnesium hydroxide and aluminum hydroxide with a mass ratio of 2:1; the antistatic agent is conductive acetylene carbon black. The melt index of described high-density polyethylene resin is 5g / 10min, and density is 0.960g / cm 3 HDPE resin.

[0031] Then, prepare described carbon nanotube reinforced polyethylene pipe as follows:

[0032] 1) Pretreatment of carbon nanotubes: reflux aluminum-titanium composite coupling agent OL-AT1618 and carbon nanotubes in ethanol for 120 minutes, the mass concentration of carbon nanotubes is 2g / ml; then remove ethanol, dry, and measure the moisture content 176ppm; Among them, the mass ratio of aluminum-ti...

Embodiment 2

[0037]Raw materials are prepared according to the following parts by weight: 100 parts of high-density polyethylene; 3 parts of carbon nanotubes; 8 parts of lubricant, 4 parts of antistatic agent, and 10 parts of flame retardant; wherein, lubricant is polyethylene wax; flame retardant It is a mixture of magnesium hydroxide and aluminum hydroxide with a mass ratio of 2:1; the antistatic agent is conductive acetylene carbon black. The melt index of described high-density polyethylene resin is 5g / 10min, and density is 0.960g / cm 3 HDPE resin.

[0038] Then, prepare described carbon nanotube reinforced polyethylene pipe as follows:

[0039] 1) Pretreatment of carbon nanotubes: reflux aluminum-titanium composite coupling agent HY-133 and carbon nanotubes in isopropanol for 90 minutes, the mass concentration of carbon nanotubes is 1g / ml, then remove ethanol, dry, and water content The measured value is 207ppm; among them, the mass ratio of aluminum-titanium composite coupling agent...

Embodiment 3

[0044] Raw materials are prepared according to the following parts by weight: 90 parts of high-density polyethylene; 1 part of carbon nanotube; 5 parts of lubricant, 6 parts of antistatic agent, and 8 parts of flame retardant; wherein, lubricant is magnesium stearate; flame retardant The agent is a mixture of magnesium hydroxide and aluminum hydroxide at 2:1.1; the antistatic agent is conductive acetylene carbon black. The melt index of described high-density polyethylene resin is 10g / 10min, and density is 0.958g / cm 3 HDPE resin.

[0045] Then, prepare described carbon nanotube reinforced polyethylene pipe as follows:

[0046] 1) Pretreatment of carbon nanotubes: reflux the aluminum-titanium composite coupling agent OL-AT1618 and carbon nanotubes in ethanol for 30 minutes, the mass concentration of carbon nanotubes can be 0.5g / ml, then remove ethanol, dry, and measure the moisture content 135ppm was obtained; among them, the mass ratio of aluminum-titanium composite coupling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com