Composite silver stannic oxide electric contact material and preparation method thereof

An electrical contact material, silver tin oxide technology, used in contacts, circuits, electrical switches, etc., to shorten the production cycle, improve electrical contact performance, and diversify selection and addition methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

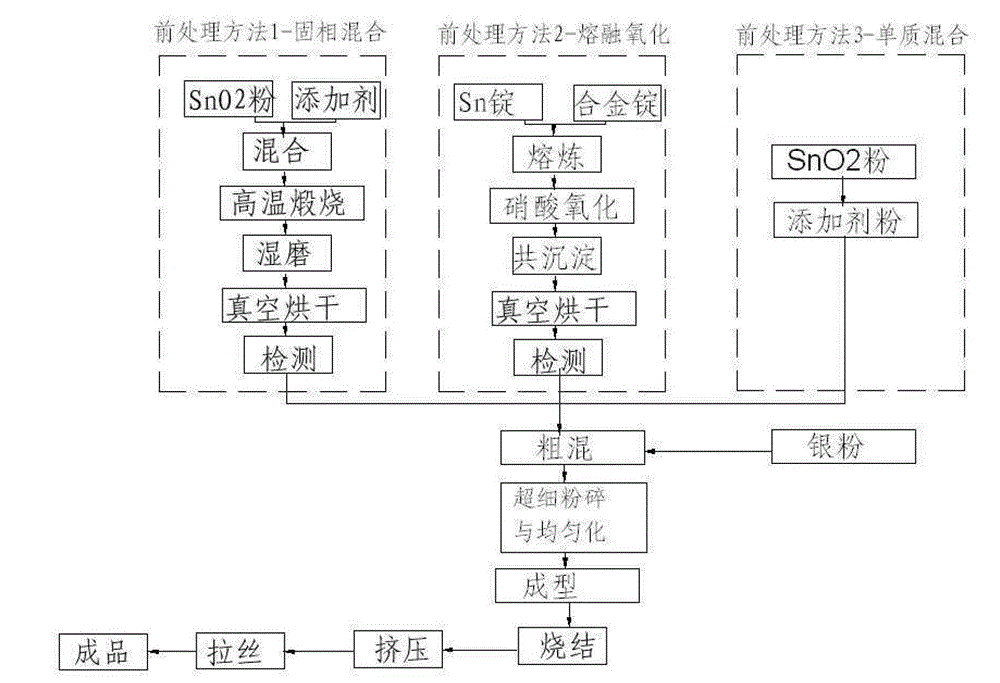

Method used

Image

Examples

Embodiment 1

[0037] Weigh 4.240 kg of SnO 2 Powder, 0.505 kg Bi 2 o 3 powder, 0.255 kg of CuO powder, a total of 5 kg of oxide powder, ball milled in a planetary ball mill and mixed for 60 minutes, the mixed SnO 2 The powder is calcined in a high-temperature calciner. During calcination, it is kept at 100°C for 0.5 hours, at 520°C for 0.5 hours, and at 1100°C for 2 hours. Calcined composite SnO 2 The powder was wet milled in a stirring ball mill for 2 hours, and the grinding medium used in the wet milling was 3 mm ZrO 2 Ball, SnO 2 The ratio of powder to water is 0.5, and the ball powder ratio is 3.0. SnO after wet milling 2 Powder detection of SnO with laser particle size analyzer 2 The particle size of the powder should ensure that D50 is 1.5-2.5 microns, D90 is 2.5-5 microns, and the particles larger than 10 microns should be less than 3%. Dry the wet-milled SnO in a vacuum oven 2 pink.

[0038] Accurately weigh 3 kg of treated SnO 2 Dry powder, add 22 kg of 200-mesh aerosoli...

Embodiment 2

[0045] Weigh 4.49 kg of tin ingot, 0.408 kg of indium ingot, and 0.102 kg of antimony ingot, smelt and cast tin flower at low temperature in an intermediate frequency furnace, put the tin flower into a 50L stainless steel bucket, add 15L of 35% nitric acid, and stir while reacting After 1.5 hours, add 5L of 35% nitric acid, react for another 2 hours, then heat the metastannic acid slurry after the reaction for deacidification treatment, add ammonia water to precipitate after cooling, adjust the pH value to 7.5-9, and then process it The metastannic acid slurry was filtered, cleaned, and vacuum dried.

[0046] The above-mentioned dried powder is calcined in a high-temperature calciner. During the calcining, it is kept at 100° C. for 1 hour, at 500° C. for 0.5 hours, and at 950° C. for 2 hours. Others are with embodiment 1.

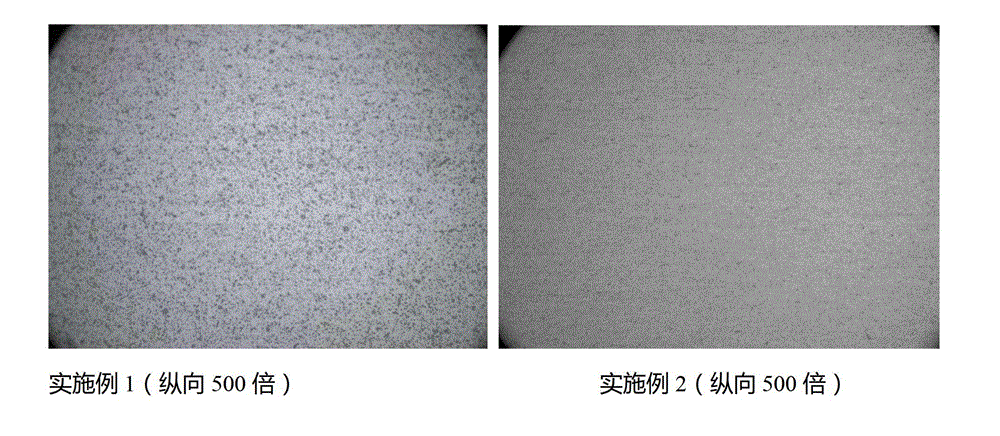

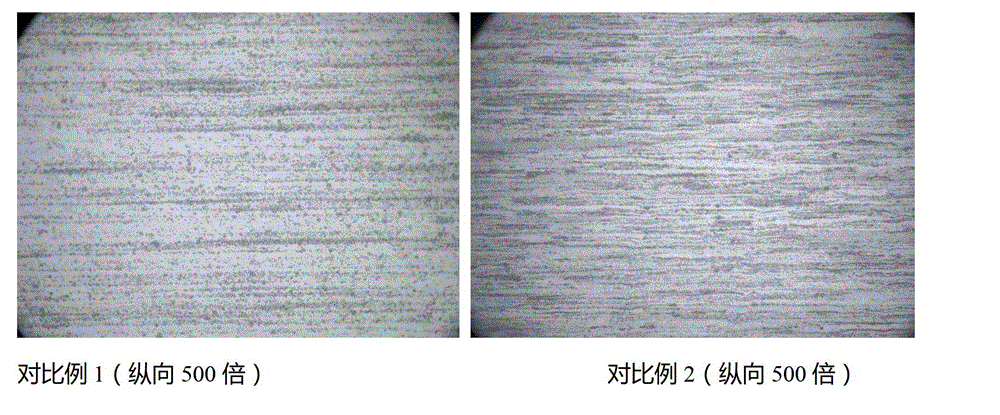

[0047] The results of scanning electron microscope analysis of the cross-section of the wire product show that SnO 2 The particle size is between 0.3-0.8...

Embodiment 3

[0051] Weigh 4.5 kg of SnO 2 powder, added to an aqueous solution composed of 0.35 kg of indium nitrate and 0.15 kg of bismuth nitrate, added ammonia water at a high speed to a pH value between 5.0 and 6.5 to form a precipitate of bismuth and indium ions in the form of hydroxide, and filter and clean the precipitate. Vacuum drying, the obtained powder is calcined in a high-temperature calciner. During calcination, it is kept at 100°C for 1 hour, at 250°C for 1 hour, at 560°C for 1 hour, and at 1050°C for 2 hours. Others are with embodiment 1.

[0052] for diameter 1.9 Wire products are tested for rivet processing performance, rivet specifications The rivet cracking rate is less than 0.1%, and the clamping cracking rate is less than 0.5%, indicating that the rivet processing performance of the wire is better than that of Example 1.

[0053] The scanning electron microscope analysis results of the cross-section of the wire product show that the SnO2 particle size is betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com