Ultrasonic radiation preparation method for chrysanthemum-like nano-palladium aggregate material

A technology of ultrasonic radiation and nano-palladium, which is applied in the field of ultrasonic radiation preparation of chrysanthemum-shaped nano-palladium aggregate materials, can solve the problems of cumbersome product purification process, environmental pollution of additives, unfavorable large-scale production, etc., and achieve easy control of reaction rate and production The effect of short cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Add 50mL of water and 10mL of ethanol to the reactor to obtain a water-ethanol mixed solvent system;

[0026] 2. Put 2.8×10 -5 mol of PdCl 2 , 8.4×10 -6 mol of PVP and 1.96×10 -5 mol of SDS was added to the water-ethanol mixed solvent system, the temperature was controlled at 40-45°C, and N 2 Protection, N 2 The flow rate was 50mL / min, the ultrasonic instrument was turned on, the ultrasonic output power was controlled at 400W, the ultrasonic reaction was 60min, and the ultrasonic was stopped to obtain a black suspension.

[0027] 3. The black precipitate obtained in the reaction solution was separated by centrifugation, washed with ethanol and acetone by centrifugation, and vacuum-dried at 40° C. for 16 hours to obtain a chrysanthemum-shaped nano-palladium aggregate material.

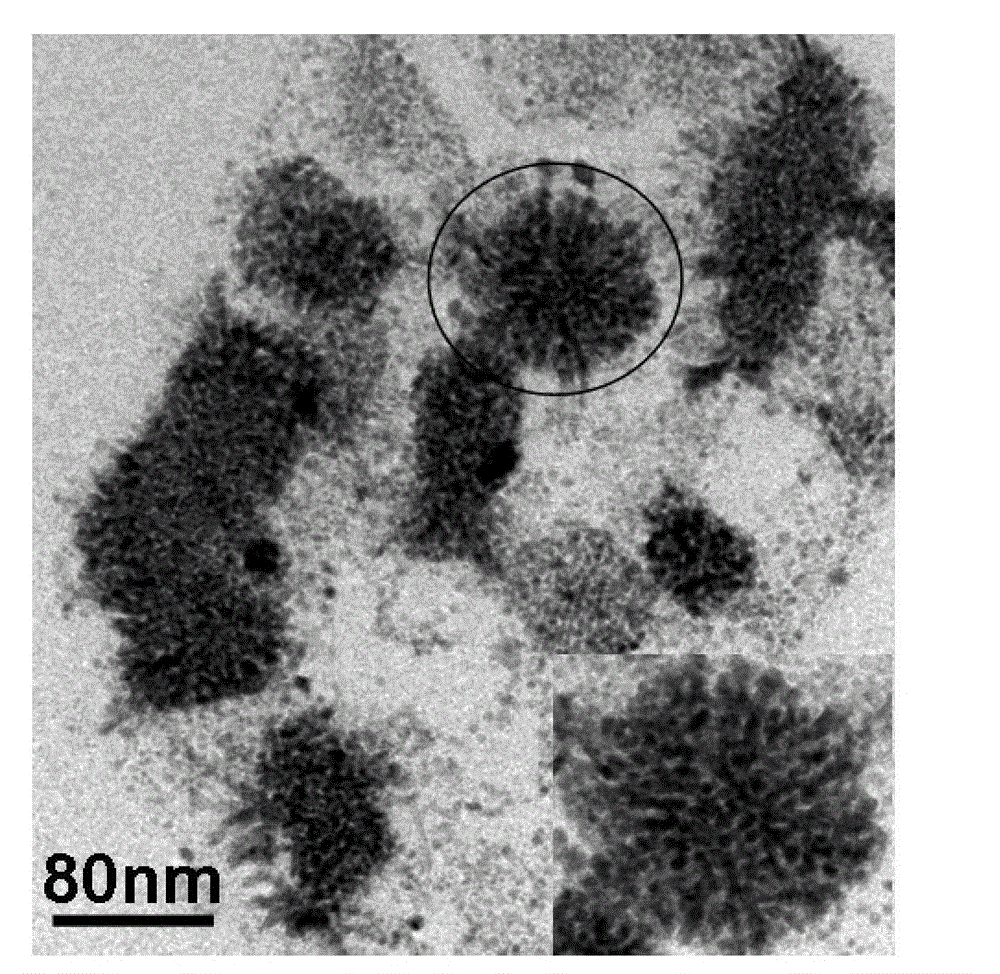

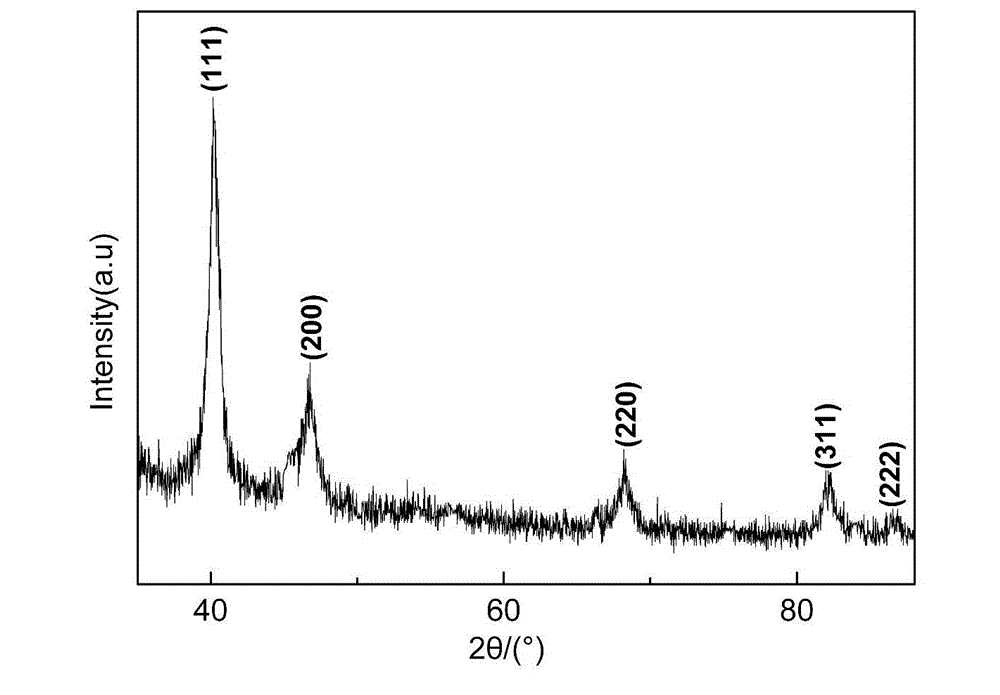

[0028] The microscopic morphology of the chrysanthemum-shaped nano-palladium aggregate material prepared in this example is shown in the attached figure 1 As shown, the aggregates look l...

Embodiment 2

[0030] 1. Add 40mL of water and 8mL of ethanol to the reactor to obtain a water-ethanol mixed solvent system;

[0031] 2. Set 2.24×10 -5 mol of PdCl 2 , 6.72×10 -6 mol of PVP and 1.57×10 -5 mol of SDS was added to the water-ethanol mixed solvent system, the temperature was controlled at 43±2°C, and N 2 Protection, N 2 The flow rate was 80mL / min, the ultrasonic instrument was turned on, the ultrasonic output power was controlled at 200W, the ultrasonic reaction was performed for 90min, and the ultrasonic was stopped to obtain a black suspension.

[0032] 3. The black precipitate obtained in the reaction solution was separated by centrifugation, washed with ethanol and acetone, and vacuum-dried at 40° C. for 12 hours to obtain a chrysanthemum-shaped palladium nano-aggregate material with an average aggregate size of about 60 nm.

Embodiment 3

[0034] 1. Add 60mL of water and 12mL of ethanol to the reactor to obtain a water-ethanol mixed solvent system;

[0035] 2. Set 3.36×10 -5 mol of PdCl 2 , 1.01×10 -5 mol of PVP and 2.35×10 -5 mol of SDS was added to the water-ethanol mixed solvent system, the temperature was controlled at 43±2°C, and N 2 Protection, N 2 The flow rate was 40mL / min, the ultrasonic instrument was turned on, the ultrasonic output power was controlled at 600W, the ultrasonic reaction was performed for 45min, and the ultrasonic was stopped to obtain a black suspension.

[0036] 3. The black precipitate obtained in the reaction solution was separated by centrifugation, washed with ethanol and acetone, and vacuum-dried at 40° C. for 24 hours to obtain a chrysanthemum-shaped palladium nano-aggregate material with an average size of about 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com