Waterborne polyurethane resin emulsion and preparation method thereof, two-component waterborne silver powder coating composition and preparation method thereof

A technology of water-based polyurethane and resin emulsion, which is applied in the direction of coating, etc., can solve the problems of easy aggregation of aluminum powder, poor chemical corrosion resistance and hardness of coating, poor arrangement of silver powder, etc., to prevent aggregation and settlement, and good chemical corrosion resistance , the effect of good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

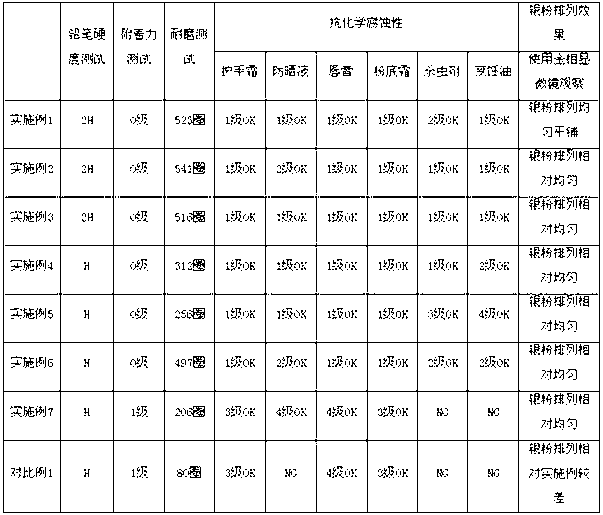

Examples

preparation example Construction

[0021] The preparation method of the water-based polyurethane resin emulsion of the present invention comprises the steps of: 1) drying and dehydrating the polymer diol and the catalyst, and then adding diisocyanate to react to obtain a prepolymer; Resin and the prepolymer obtained in step 1) are mixed to obtain resin I, and resin I is mixed with a hydrophilic chain extender to obtain resin II, and neutralizing agent and chain terminator are sequentially added to resin II to obtain resin III; 3) To the resin III obtained in step 2), add the solvent deionized water, initiator and organic fluorine resin in sequence to obtain a water-based polyurethane resin emulsion.

[0022] The preparation method of the water-based polyurethane resin emulsion provided by the present invention can specifically be described as: 1) Mix the vinyl acetate resin with methanol, modify the vinyl acetate resin under the action of alkali catalysis, and obtain the hydroxyl modified polyvinyl alcohol conta...

Embodiment 1

[0041]Step 1. Preparation of water-based polyurethane resin emulsion: Step 1.1. Add 210 g of methanol and 5 g of NaOH into a four-necked flask, and heat in a water bath at 45° C. for 15 min. Add 70g of vinyl chloride resin (cp-710 from Sunshine Chemical Co.), react for 9 hours, and discharge to obtain hydroxyl-modified binary vinyl vinyl resin for later use; step 1.2, add polymerization Diol (Shanghai BYU Technology Development Co., Ltd., polyether polyol 330N) and catalyst (10wt% solution of dibutyltin diacetate) were dried and dehydrated under nitrogen at 150°C for 1 h, and then diisocyanate (IPDI from Bayer, Germany) was added. ), reacted at 85°C for 1.5h. Then add acetone to reduce the viscosity of the system, and add 10g of the hydroxyl-modified divinyl chloride resin obtained in step 1.1, and copolymerize at 85°C for 2 hours, then add a hydrophilic chain extender (DMPA (dimethylol propionic acid)) and stir After reacting for 1.5h, the temperature was lowered to 45°C, an...

Embodiment 2

[0044] Change each component content by each component content shown in embodiment 2 column in table 1, other are all the same with embodiment 1, by the solid content of the aqueous polyurethane resin emulsion that step 1) obtains is 36%, finally obtains two-component Waterborne polyurethane silver powder coating S2.

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com