Method for determining arsenic, antimony and bismuth content of pure chromium by using atomic fluorescence spectrometry

A technique of atomic fluorescence spectroscopy and pure chromium, which is applied in the field of alloy trace element analysis, can solve the problems of high maintenance cost, expensive equipment, strict requirements on the environment and reagents, etc., to save manpower and material resources, low maintenance cost, and wide range of measurement wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

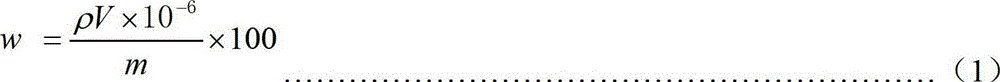

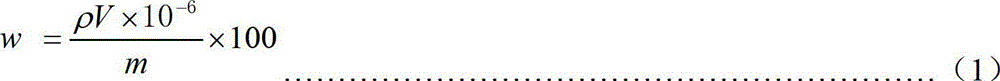

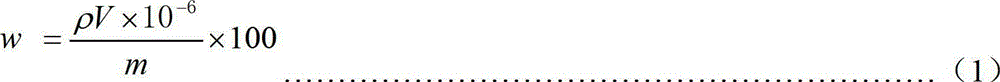

[0055] Determination of arsenic, antimony and bismuth content in pure chromium (mass fraction not less than 99.99%) for refining superalloys, the technical specifications stipulate that As≤0.0005%, Sb≤0.0005%, Bi≤0.0005%. It is characterized in that: the steps of the assay method are:

[0056] (1) The reagents used in the determination process of this method are:

[0057] 1.1 Hydrochloric acid, ρ1.19g / mL; superior grade or MOS grade;

[0058] 1.2 Nitric acid, ρ1.42g / mL; superior grade or MOS grade;

[0059] 1.3 Sulfuric acid 1+1, superior grade;

[0060] 1.4 Sulfuric acid 1+4, superior grade;

[0061] 1.5 Citric acid solution, 400g / L, the preparation method is to weigh 400g of high-grade pure citric acid and place it in a 500mL beaker. After the solution is completely dissolved, transfer it into a 1000mL volumetric flask, dilute with water to the mark, and mix well;

[0062] 1.6 The mixed solution of thiourea-ascorbic acid is prepared by weighing 10g of superior pure thiou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com