Integrated method for operating temperature controllable multi-chip modules

A technology of multi-chip components and integration methods, applied in electrical components, electrical solid-state devices, semiconductor devices, etc., can solve problems such as heat conduction, achieve stable and reliable work, improve long-term reliability, and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

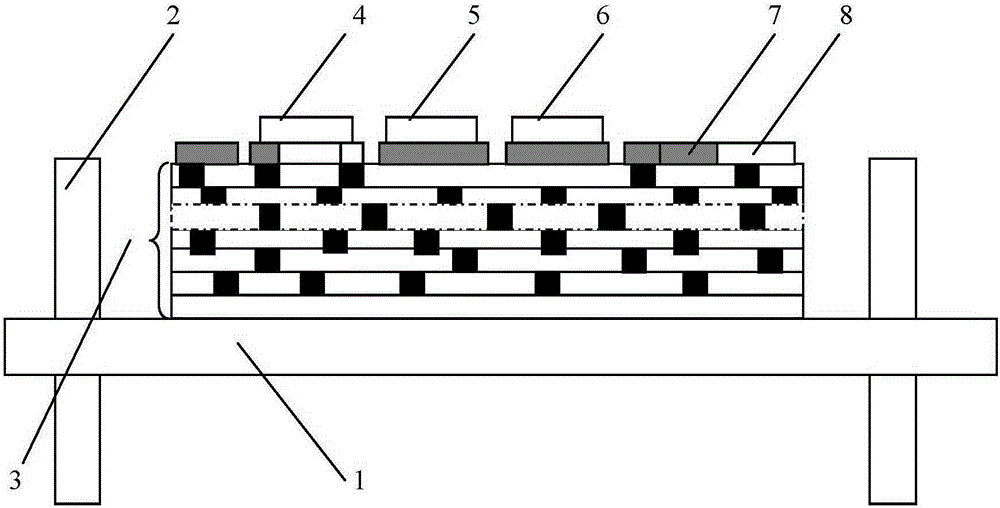

[0017] Embodiment 1: the original integrated process such as Figure 4 As shown, the process is briefly described as follows:

[0018] (1) Casting: By changing the material type and ratio, the substrate with expected design requirements (such as thermal conductivity, dielectric constant, loss factor, insulation resistance, breakdown voltage, etc.) can be obtained. According to the design requirements, the proportioning of the slurry is completed, and the slurry is cast on the tape casting machine along the substrate film into a thin sheet; at this time, it becomes a raw porcelain material, which is rolled into a roll after pre-drying, and is ready for use;

[0019] ⑵Cutting piece: The surface inspection of the rolled green ceramic sheet after casting is carried out and cut into ceramic blocks of specified size, that is, block blocks;

[0020] (3) Punching: In order to make the interconnection structure of each layer of LTCC, it is necessary to punch through holes or positioni...

Embodiment 2

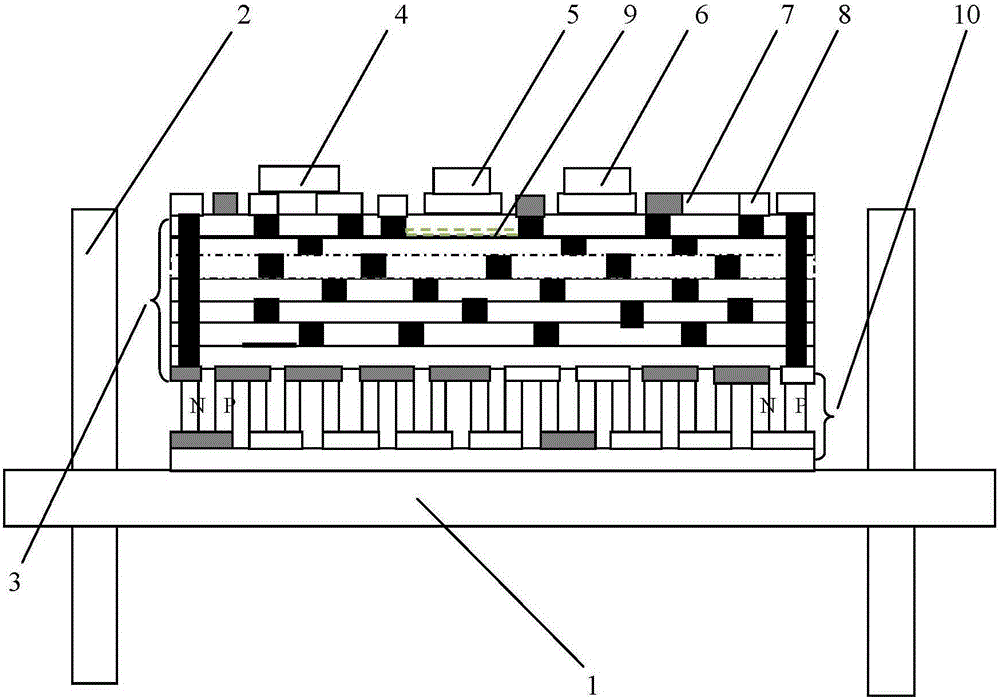

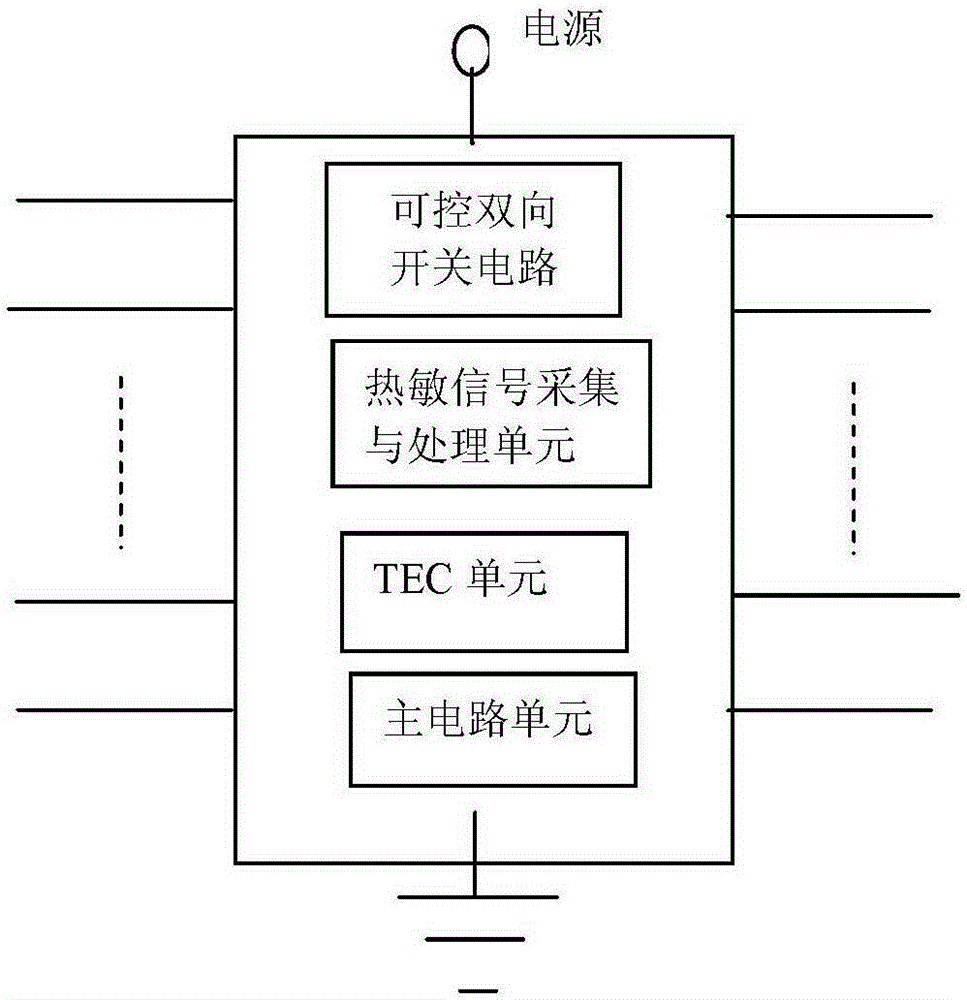

[0035] Embodiment 2 The technological process of the present invention is as Figure 5 Shown; The present invention, on the basis of original flow process, increases thick-film thermistor slurry screen printing and sintering, LTCC substrate back side thick-film conductor slurry screen printing and solidification, the preparation and processing of TEC substrate ceramic substrate The printing and sintering of thick film conduction tape, the preparation of N-type and P-type semiconductor grains required by TEC, the integration of PTCC and TEC, etc. The overall process flow is briefly described as follows:

[0036] (1) Casting: By changing the material type and ratio, the substrate with design requirements (such as thermal conductivity, dielectric constant, loss factor, insulation resistance, breakdown voltage, etc.) can be obtained. According to the design requirements, the proportioning of the slurry is completed, and the slurry is cast on the tape casting machine along the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com