Electrode for secondary cell, method for producing the same, and secondary cell

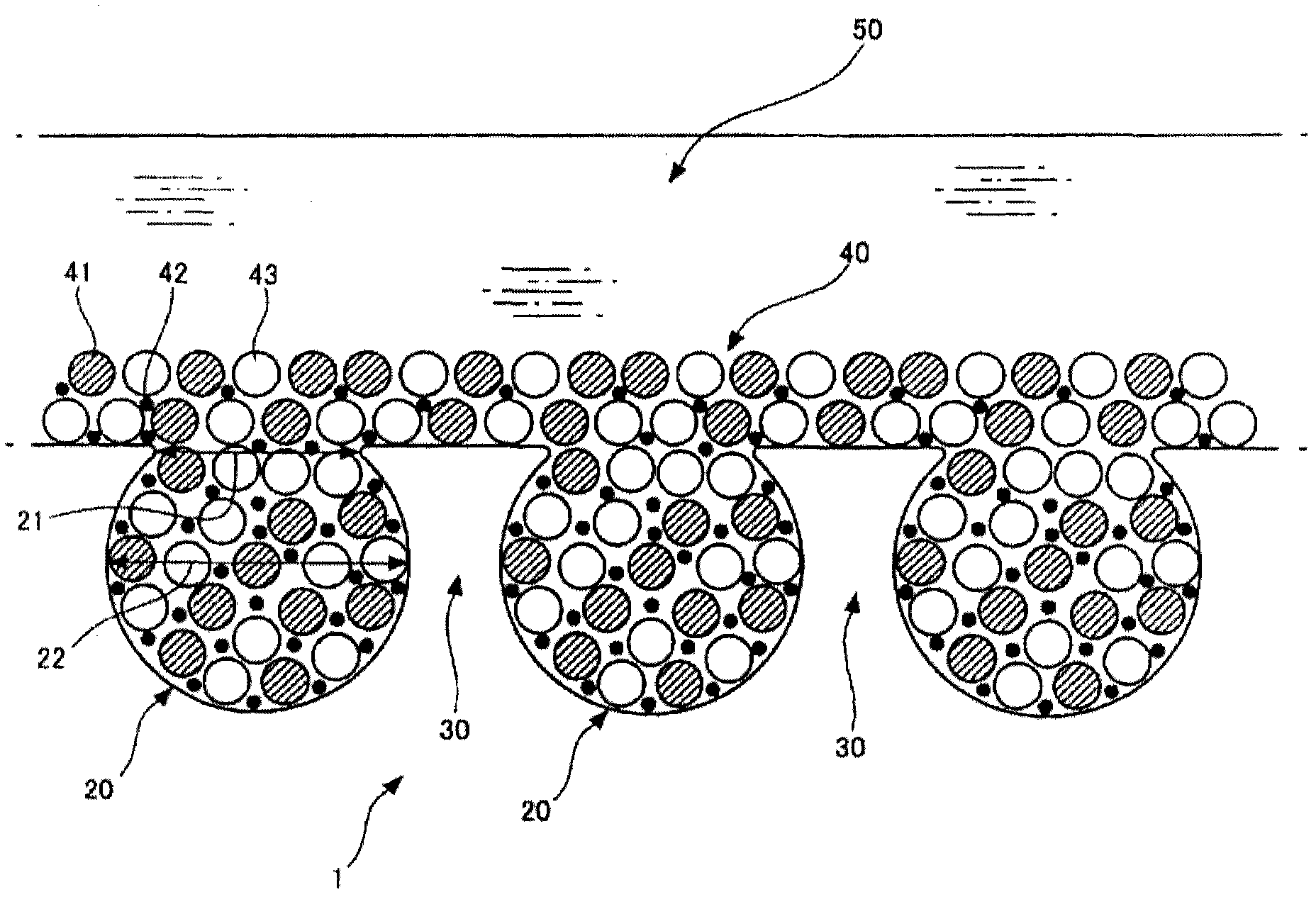

A secondary battery and electrode technology, which is applied in the direction of electrode manufacturing, battery electrodes, electrode collector coating, etc., can solve the problems of battery internal resistance increase, achieve the effects of suppressing internal resistance, expanding contact area, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

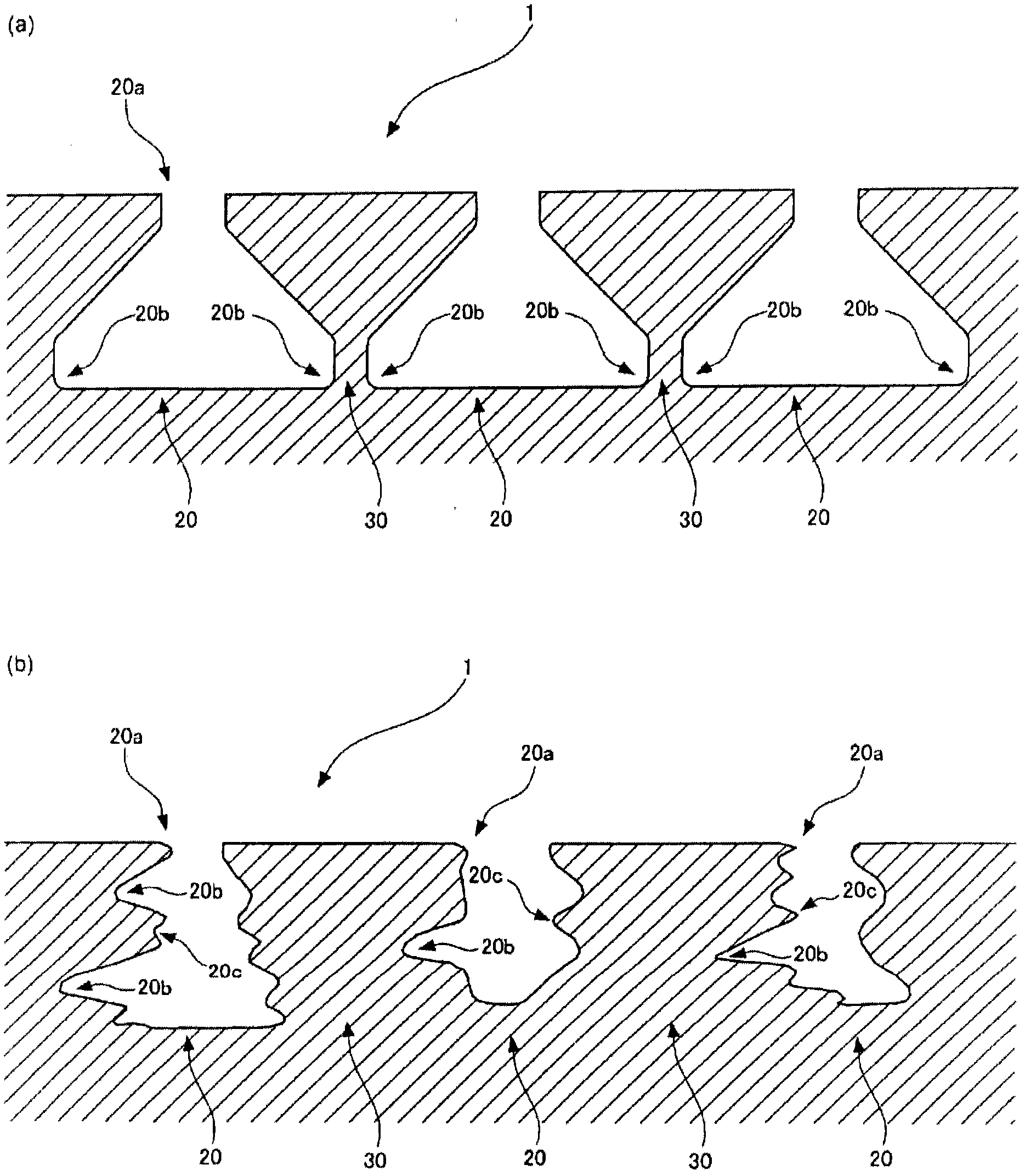

[0033] (Manufacture of electrodes for secondary batteries by chemical etching method (1))

[0034] In the case of using aluminum foil to form the current collector, it contains 5 to 30% by weight of inorganic acid (the same below), 1.5 to 9% of iron ions as a source of ferric ion, and 0.02 to 1.5% of manganese ions as a source of manganese ions. And aluminum or aluminum alloy surface roughening agent of 0.05-1% aqueous solution of copper ion as divalent copper ion.

[0035] In this case, examples of the inorganic acid include hydrochloric acid, sulfuric acid, nitric acid, phosphoric acid, perchloric acid, sulfamic acid and the like. The concentration of the inorganic acid is 5-30%, preferably 7-25%, more preferably 12-18%. If the concentration is less than 5%, the roughening speed of aluminum is slow, and if it exceeds 30%, the crystallization of aluminum salt is likely to occur when the liquid temperature is lowered, and there is a risk of poor operability such as clogging o...

no. 2 approach

[0049] (Manufacture of electrodes for secondary batteries using chemical etching method (2))

[0050] A surface treatment agent containing divalent copper complexes containing azoles, an organic acid, and an aqueous solution to which halogen ions are added is used. The copper complex of azoles functions as an oxidizing agent for oxidizing metal copper and the like. By using a divalent copper complex of azoles among various divalent copper complexes having an oxidation function, a moderate etching rate can be exhibited as a surface treatment agent. Examples of the azoles include diazoles, triazoles, tetrazoles, derivatives thereof, and the like.

[0051] The content of the divalent copper complex of the azoles can be appropriately set according to the target oxidizing power, etc., and is preferably 1 to 15% (% by weight, the same below) in terms of solubility and stability of the complex. . The divalent copper complex of azoles may be added as a copper complex, or a divalent...

no. 3 approach

[0058] (Manufacture of electrodes for secondary batteries by electrolytic etching)

[0059] When the current collector is formed of aluminum foil, in order to perform direct current etching on the current collector, it is preferable to contain 3 to 10% of hydrochloric acid and 0.05 to 1% of oxalic acid at a liquid temperature of 50 to 80°C. In the aqueous solution, the applied current density is 100~500mA / cm 2 , The power is 30~60C / cm 2 of direct current.

[0060] In addition, in order to perform AC etching on a current collector formed of aluminum foil, preferably, in an aqueous solution containing 5 to 10% of hydrochloric acid, 0.5 to 2% of phosphoric acid, and 0.1 to 1% of sulfuric acid and having a liquid temperature of 30 to 50°C, The applied current density is 200~600mA / cm 2 , the frequency is 20~70Hz, the power is 50~100C / cm 2 of alternating current.

[0061] In addition, when the current collector is aluminum foil, lithium manganese composite oxide (Li x mn 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Average primary particle size | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com