Environment coordination type preparation method of nano titanium dioxide powder

A nano-titanium dioxide, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of difficult preparation of sol, high pollution, complex equipment, etc., to achieve environmental coordination, high product quality, The effect of uniform hole distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

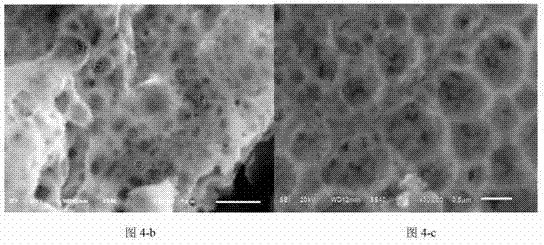

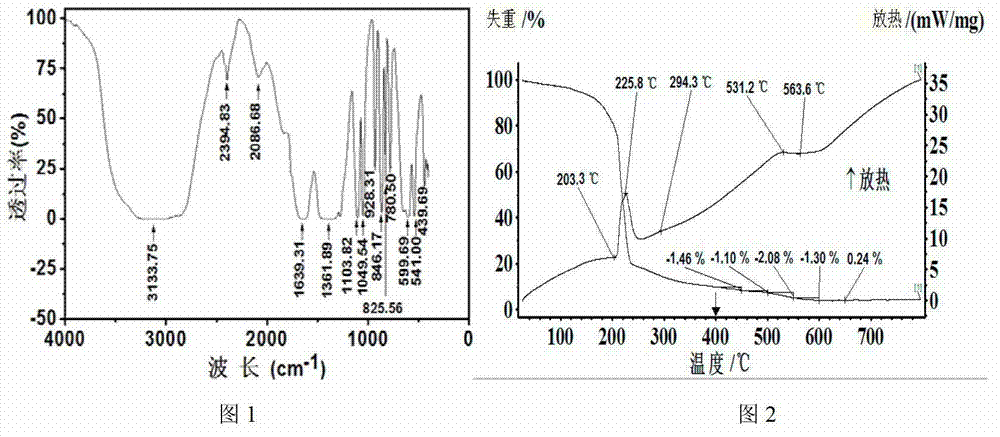

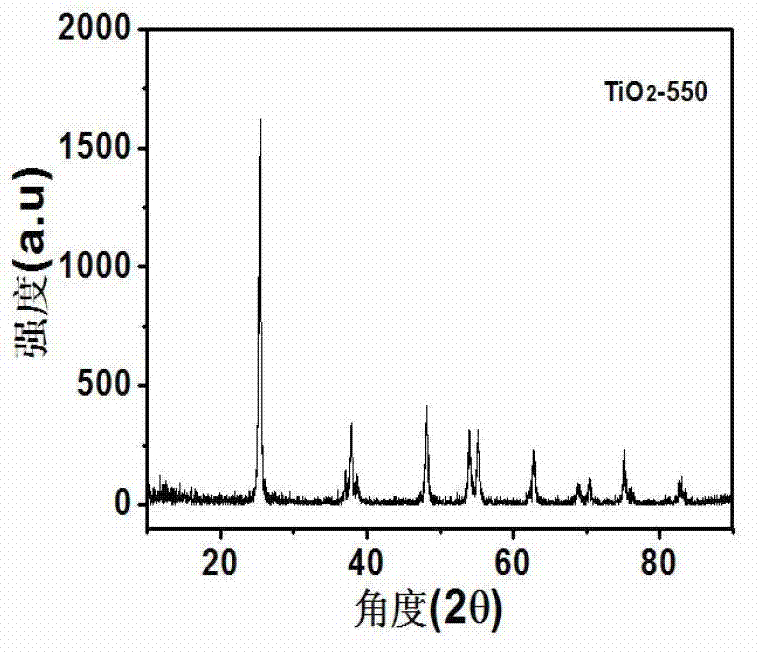

[0046] Specific embodiment 1 of the present invention, adopts novel powder preparation technology of the present invention, prepares TiO 2 (Anatase) nanopowder steps are as follows:

[0047] (1) The sol concentration is C sol-gel-Ti 4+ =0.5mol / L, 500ml, 20 grams of sample (in the final product TiO 2 mass meter);

[0048] (2) According to the material ratio of lactic acid and tetrabutyl titanate is 2.0~6.0:1.0, take 80ml of lactic acid and add it to 86.5g of tetrabutyl titanate, exothermic reaction, after fully stirring, add 100ml of water and 40ml of concentrated nitric acid, stir evenly until the yellow color is clear and transparent, and A liquid is obtained;

[0049] (3) At room temperature, use ammonia water to adjust the pH of A solution to 3.0~5.0, and then add water until the total volume of the sol is 500ml;

[0050] (4) After continuous stirring, the mixed liquid will be yellow, clear and transparent, and after aging, a water-based stable sol will be obtained, an...

specific Embodiment 2

[0058] Specific embodiment 2 of the present invention adopts the novel powder preparation technology of the present invention to prepare TiO 2 (coexistence structure of anatase and rutile) the steps of nanopowder are as follows:

[0059] (1) The sol concentration is C sol-gel-Ti 4+ =0.5mol / L, 500ml, 20 grams of sample (in the final product TiO 2 mass meter);

[0060] (2) According to the material ratio of lactic acid and tetrabutyl titanate is 2.0~6.0:1.0, take 100ml of lactic acid and add it to 86.5 grams of tetrabutyl titanate, exothermic reaction, after fully stirring, then add 100ml of water and 40ml of concentrated nitric acid, stir evenly until the yellow color is clear and transparent, and A liquid is obtained;

[0061] (3) At room temperature, use ammonia water to adjust the pH of A solution to 3.0~5.0, and then add water until the total volume of the sol is 500ml;

[0062] (4) Stir continuously until the yellow color is clear and transparent, and the sol is obtai...

specific Embodiment 3

[0069] Specific embodiment 3 of the present invention adopts the novel powder preparation technology of the present invention to prepare TiO 2 (Rutile) nano powder steps are as follows:

[0070] (1) The sol concentration is C sol-gel-Ti 4+ =0.5mol / L, 500ml, 20 grams of sample (in the final product TiO 2 mass meter);

[0071] (2) According to the material ratio of lactic acid and tetrabutyl titanate is 2.0~6.0:1.0, take 130ml lactic acid and add it to 86.5g tetrabutyl titanate, exothermic reaction, after fully stirring, then add 100ml water and 40ml of concentrated nitric acid, stir evenly until the yellow color is clear and transparent, and A liquid is obtained;

[0072] (3) At room temperature, use ammonia water to adjust the pH of A solution to 3.0~5.0, and then add water until the total volume of the sol is 500ml;

[0073] (4) Stir continuously until the yellow color is clear and transparent, and the sol is obtained after aging;

[0074] (5) At 140°C, after removing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com