Method for improving in-situ activation and modification efficiency of suspended filter material

A suspended filter material, in-situ technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Complex problems such as improving the efficiency of in-situ activation and modification, reducing equipment footprint and investment, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

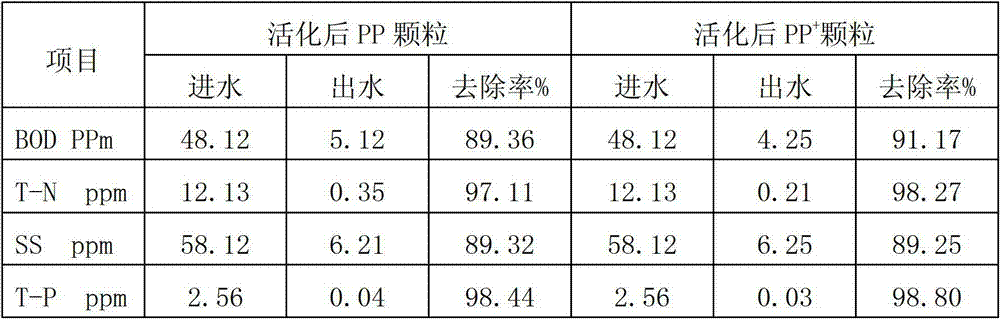

Embodiment 1

[0035] 1. Take 5m wood chips with a moisture content of 10% 3 Placed in a volume of 10m 3 In the inner cylinder of the hydrothermal reaction equipment, the valve is closed, and the saturated steam generated by the hot boiler is continuously introduced for 15 minutes. The temperature of the saturated steam is controlled at 200°C and the pressure is 1.8Mpa, and the hydrothermal reaction is carried out for 15 minutes. After the reaction is over, the pressure relief valve is automatically opened for pressure relief. After the hydrothermal reaction, the sawdust is expanded during the sudden depressurization process of the saturated steam. When the temperature in the hydrothermal reaction device drops to room temperature, the expanded wood chips in the hydrothermal reaction inner cylinder are taken out and mechanically crushed, and the crushing particle size is controlled. At 5-10 microns, the fine powder of active wood material is made. At this time, the fine powder of active wood...

Embodiment 2

[0055] 1. Take 5m wood chips with a moisture content of 5% 3 Placed in a volume of 10m 3 In the inner cylinder of the hydrothermal reaction equipment, the valve is closed, and the saturated steam generated by the hot boiler is continuously introduced for 20 minutes. The temperature of the saturated steam is controlled at 250°C and the pressure is 2.4Mpa, and the hydrothermal reaction is carried out for 20 minutes. After the reaction is over, the pressure relief valve is automatically opened for pressure relief. After the hydrothermal reaction, the sawdust is expanded during the sudden depressurization process of the saturated steam. When the temperature in the hydrothermal reaction device drops to room temperature, the expanded wood chips in the hydrothermal reaction inner cylinder are taken out and mechanically crushed, and the crushing particle size is controlled. At 5-10 microns, the fine powder of active wood material is made. At this time, the fine powder of active wood ...

Embodiment 3

[0075] 1. Take 5m wood chips with a moisture content of 7% 3 Placed in a volume of 10m 3 In the inner cylinder of the hydrothermal reaction equipment, the valve is closed, and the saturated steam generated by the hot boiler is continuously introduced for 20 minutes. The temperature of the saturated steam is controlled at 180°C and the pressure is 1.7Mpa, and the hydrothermal reaction is carried out for 10 minutes. After the reaction is over, the pressure relief valve is automatically opened for pressure relief. After the hydrothermal reaction, the sawdust is expanded during the sudden depressurization process of the saturated steam. When the temperature in the hydrothermal reaction device drops to room temperature, the expanded wood chips in the hydrothermal reaction inner cylinder are taken out and mechanically crushed, and the crushing particle size is controlled. At 5-10 microns, make active wood material micropowder, at this time, the carboxyl acidic activation group cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com