Lead strontium titanate thin film and production method thereof

A strontium lead titanate thin-film technology, applied in the field of ferroelectric materials, achieves good application prospects, optimized tuning rate, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides thin film preparation at different positions: axial and eccentric sputtering (the axis normal of the target and the center normal of the material do not coincide). Optionally, during the sputtering process, the axis normal of the film deviates from the target center normal by 0-40 degrees.

[0034] The above base layer is Si substrate or single crystal substrate, such as: MgO, LaAlO 3 、Al 2 o 3 and SrTiO 3 Wait.

[0035] Regarding the preparation process of the target material, for example, the following two steps may be included:

[0036] 1) Use strontium carbonate, titanium oxide and dilead trioxide powders according to the required stoichiometric ratio (compared with the required film composition, Pb excess 25wt%, Sr excess 6wt%), and use agate balls for coarse grinding 24 hours, and synthesized at 850°C after drying;

[0037] 2) Finely grind the synthesized powder for 48 hours, add a binder after drying and arrange plastic, and f...

Embodiment 1

[0048] Example 1: a lead strontium titanate (PST) thin film prepared under the condition that the substrate temperature is 300°C.

[0049] The bottom electrode of lanthanum nickelate LNO with (100) orientation (on SiO 2 / Si substrate) introduced into the magnetron sputtering instrument at a position deviated from the target axis (Off axis, the normal line of the target axis is 5cm away from the normal line of the film center), and evacuated until the initial vacuum degree is less than 10 -6 Torr. Raise the substrate temperature to the required temperature to start pre-sputtering, the heating rate is 10°C / min, the sputtering power is 70W, the amount of argon introduced is 16SCCM, and the sputtering pressure is 4Pa. After the pre-sputtering time is 60min, start sputtering. According to the known sputtering rate (0.6nm / min), when the required film thickness (300nm) is reached, stop sputtering, turn off the argon gas, turn on the oxygen gas, and keep The substrate temperature wa...

Embodiment 2

[0052] Example 2: a lead strontium titanate (PST) thin film prepared under the condition that the substrate temperature is 350°C.

[0053] The same settings as in Embodiment 1 will not be described in detail again. In this embodiment, the substrate temperature is set to 350°C, the pre-sputtering is started for 60 minutes, and then the sputtering is started, and the thin film is sputtered according to the known sputtering rate. When the thickness reaches the required thickness, the sputtering is stopped. Keep the substrate temperature at 350°C, turn off the argon, turn on the oxygen, and anneal the film for 1 hour. After the annealing, lower the temperature to room temperature, turn on the magnetron sputtering instrument, and take out the film.

[0054] The upper electrode preparation and post-annealing process are the same as in Example 1.

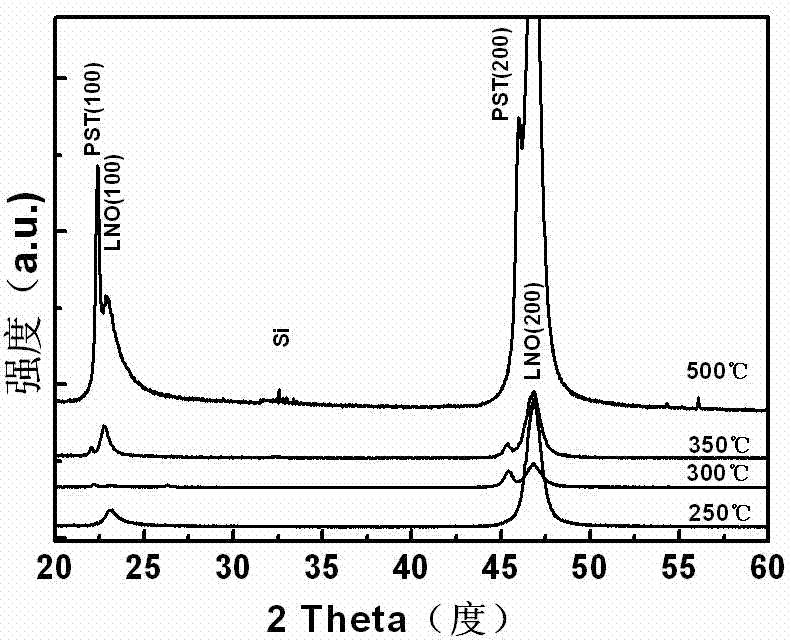

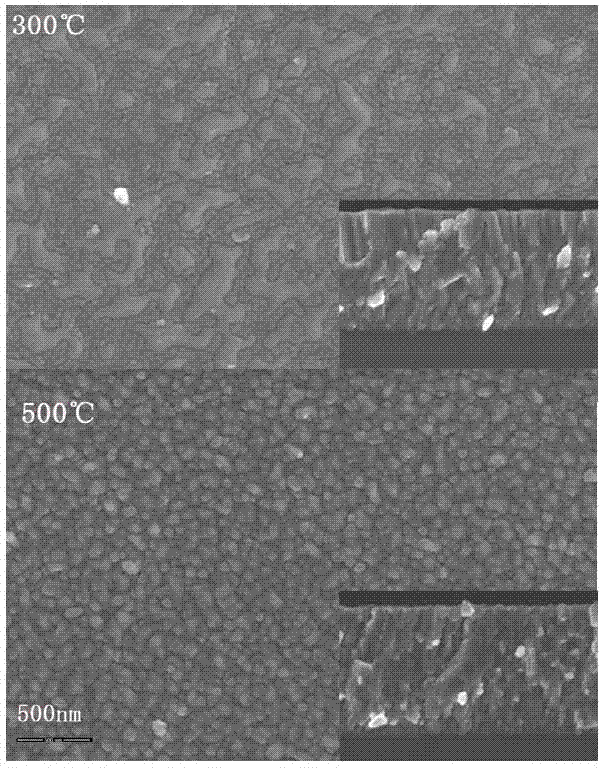

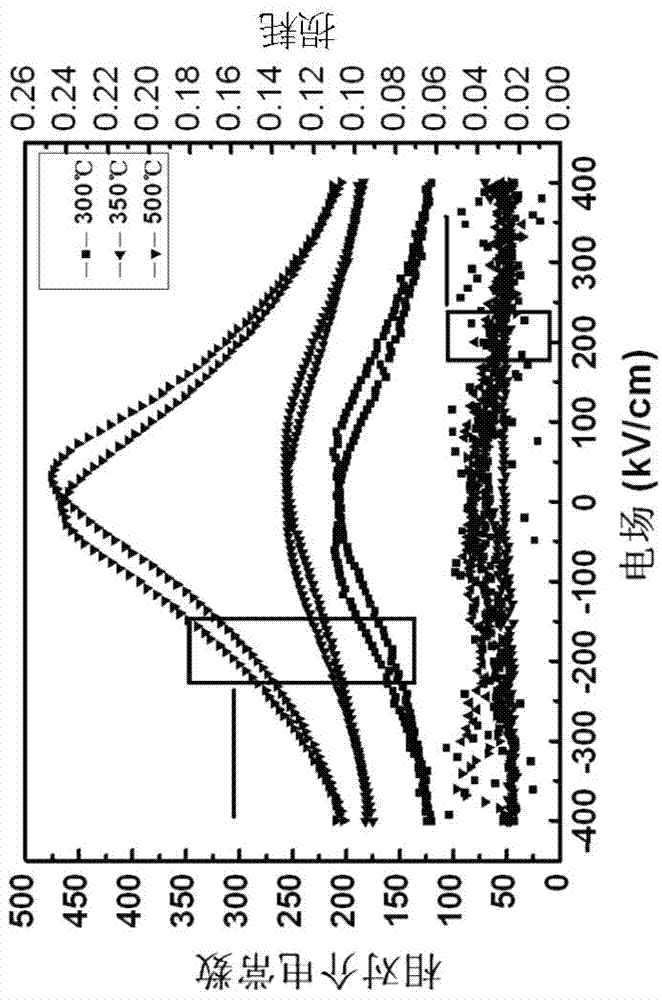

[0055] The structure and performance detection of the thin film prepared in this embodiment found that, from figure 1 It can be seen th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com