Nitrogen silicon carbide as cathode material

A negative electrode material, silicon nitride technology, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve problems such as low theoretical capacity, low potential, and the inability of materials to form large-scale manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

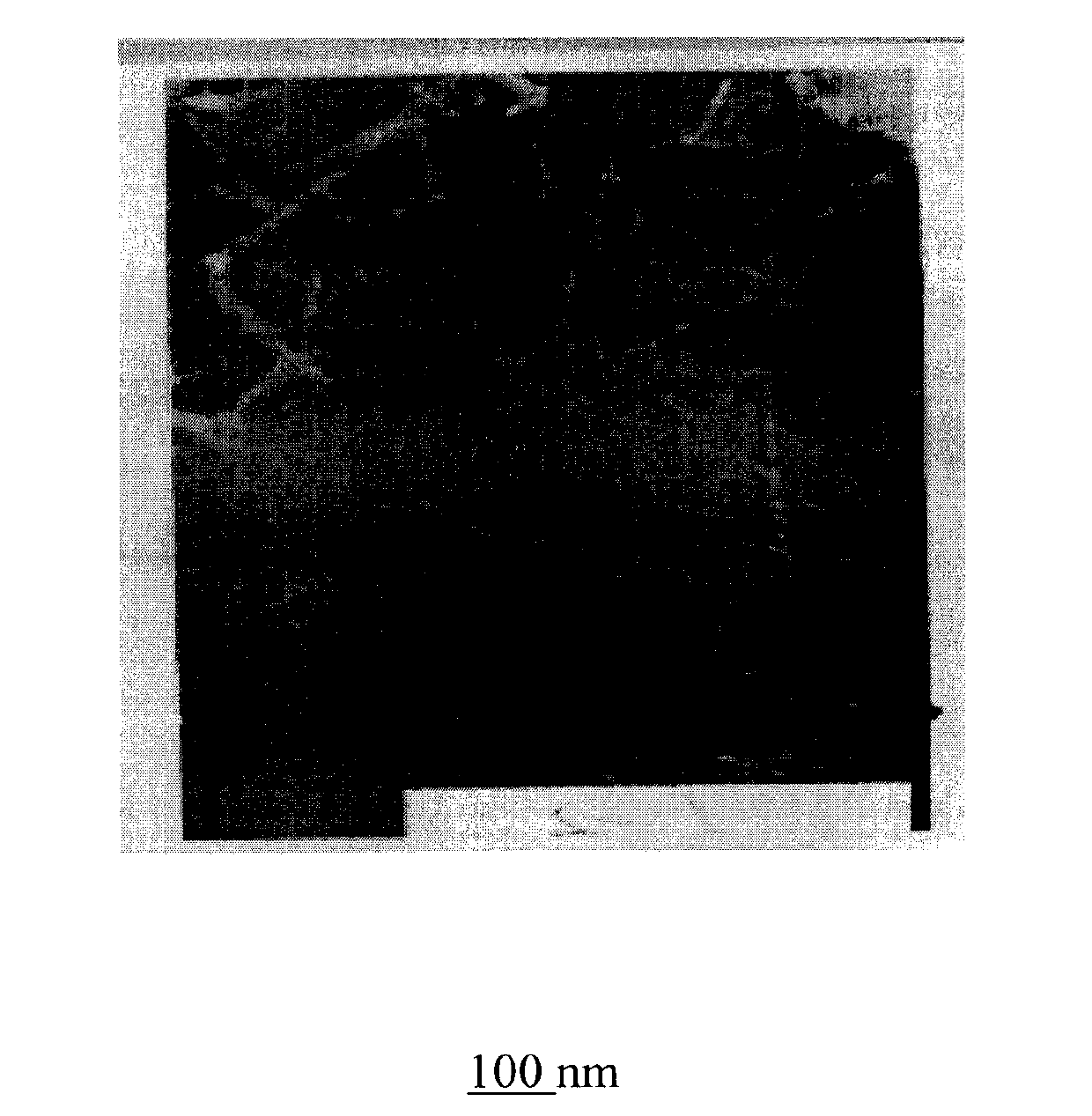

[0015] Both nano-silicon oxide and nano-carbon whiskers are self-made. The article of Frank T. Ferguson and Joseph A. Nuth published in J. Chem. Eng. Data, 2008, 53(12), pp 2824-2832 and the documents therein describe the preparation method of silicon oxide. The preparation method of nano-silicon oxide is roughly as follows: put a silicon oxide boat and silicon oxide powder in the quartz tube, evacuate, heat to 1250°C, pass in hydrogen gas, and the silicon oxide and hydrogen undergo a reduction reaction to form silicon oxide gas. Take it to the outlet condensation place, condense to form silica powder, and its particle diameter distribution is about 40-80nm. The article published by Ishioka M and Okada T et al. in Carbon, 1992, 30(7): 975 describes the preparation method of vapor-phase grown carbon nanofibers. The method is roughly to put the metal nickel particle catalyst inside the quartz tube, pass through methane with hydrogen as the carrier gas at 1100°C, and decompose i...

Embodiment 2

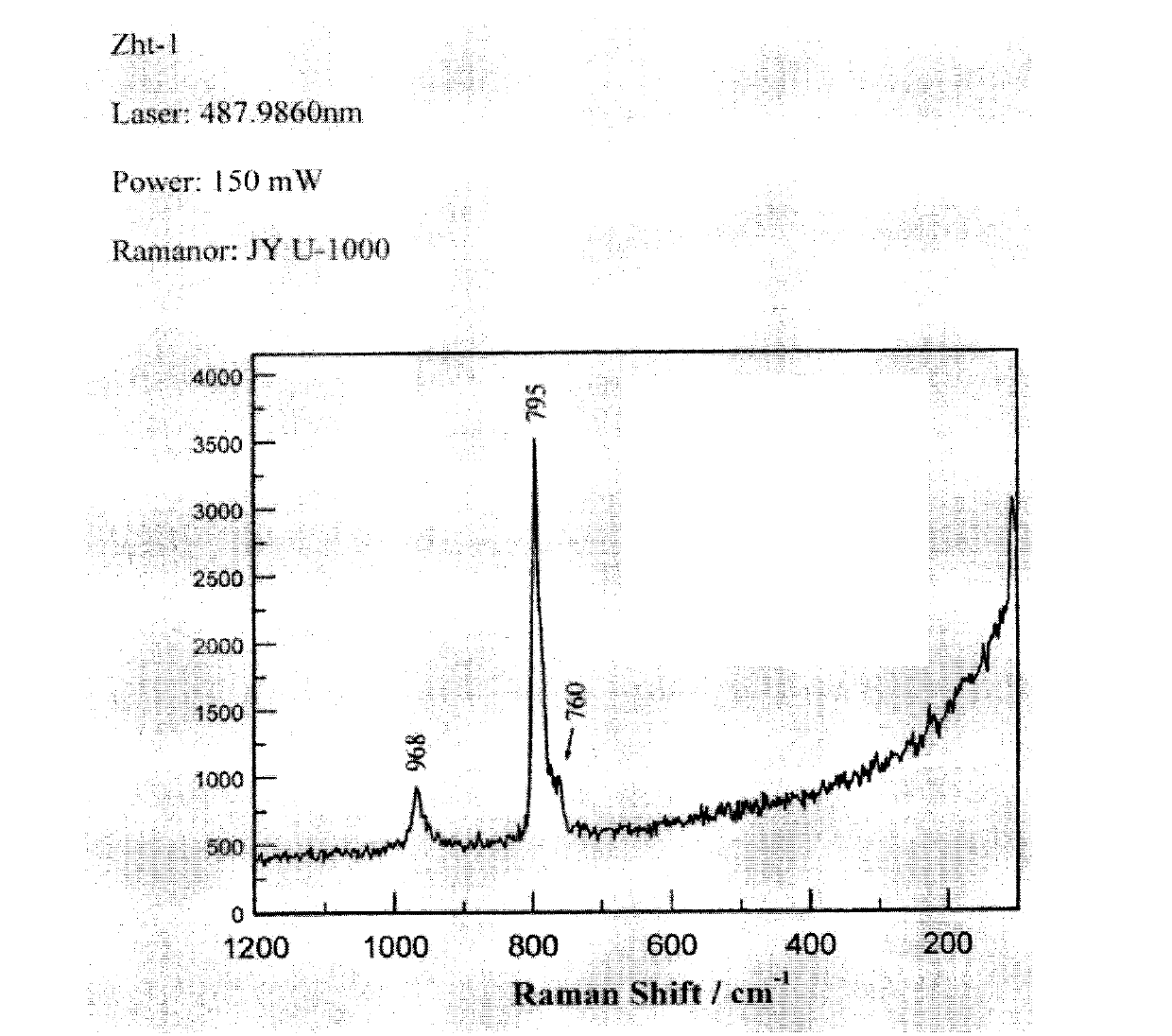

[0023]Weigh 7.14g of nano-silicon oxide powder and 9.25g of carbon fiber (all of which are 99.9% or higher in purity), and weigh another 1mg of nickel chloride powder. After mixing, put it into a graphite bowl and seal it with a lid , put it into a VSF-75 vacuum high-temperature sintering furnace, heat the mixture in an inert gas + nitrogen mixed atmosphere, raise the temperature at a rate of 25°C / min until 1700°C, maintain the heating time for 1 hour, and then naturally cool to room temperature. Open the lid of the bowl, and the product is silicon nitride, with a weight of 5.17g. In this process, the flow of nitrogen gas is adjusted to control the content of nitrogen atoms entering the growth of silicon-carbon crystals. As a doping element, it enters the silicon-carbon crystals to replace silicon or carbon atoms in the lattice, or enters the gaps, and the resulting nano-silicon-carbon crystals The cell parameters become larger. produces Si having the compound form 55 C 42 ...

Embodiment 3

[0027] The samples of Examples 8-10 listed in Table 2 were followed by the same general procedure as Examples 1-7, with the following differences. Use commercially available nano-silicon oxide (Suzhou Kai'an Coating Material Co., Ltd.), commercially available carbon nanofibers (300-600nm, aspect ratio greater than 30, ICHEL INC, Japan) to prepare silicon nitride carbide by sintering, and the cut-off temperature is 1750 ° C. The reaction time was maintained for 2 hours.

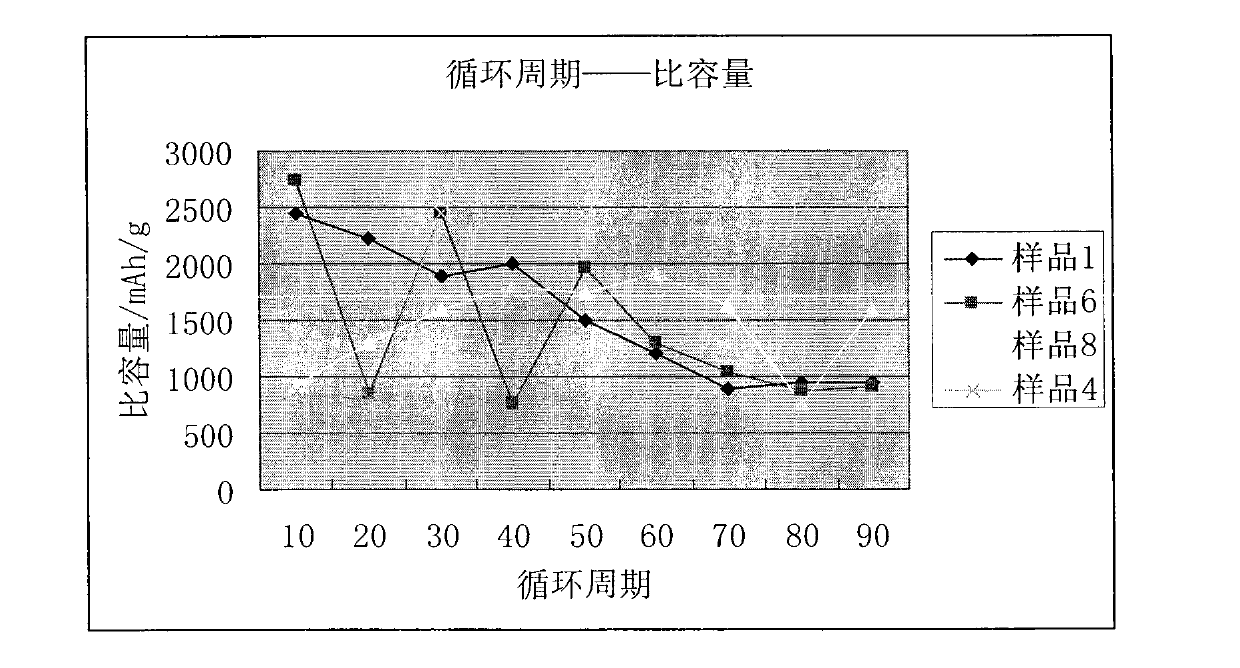

[0028] Each of the samples of Examples 1-10 listed in Table 1 was fabricated into an electrode. Cycling characterization was performed in an electrochemical cell with a lithium metal counter electrode. Electrodes were prepared as follows. Using a magnetic stirrer in a 45 ml stainless steel container, 2.9 g of silicon carbide powder, 0.22 g of conductive carbon (Shenzhen Weifeng Technology Co., Ltd.) and 1.2 g of polyvinylidene fluoride (dissolved in N-methyl- 20 weight percent solution in 2-pyrrolidone) mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com