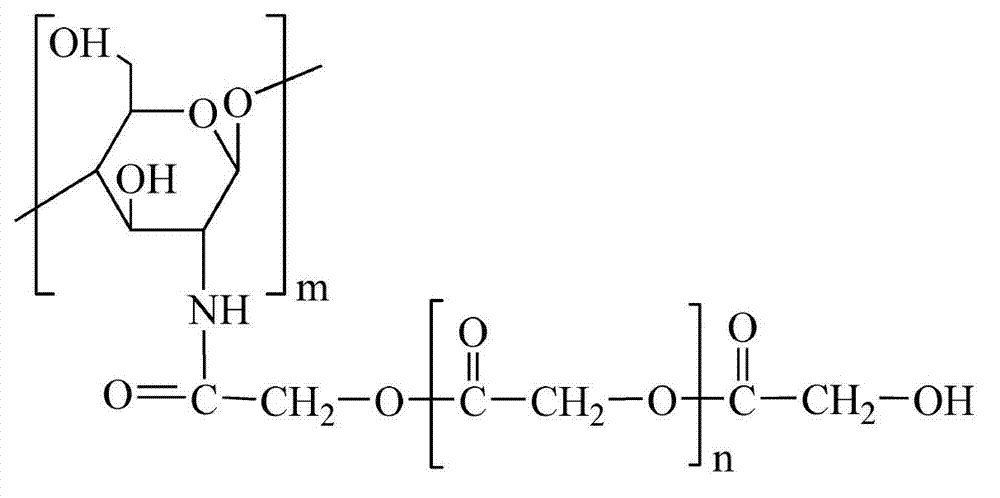

Method for preparing a chitosan / aliphatic polyester amphiphilic graft copolymer

A technology of aliphatic polyester and graft copolymer, which is applied in the field of preparation of chitosan/aliphatic polyester amphiphilic graft copolymer, can solve problems such as poor repeatability and complicated experimental process, and achieve easy separation, The synthesis method is simple and the reaction conditions are mild

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

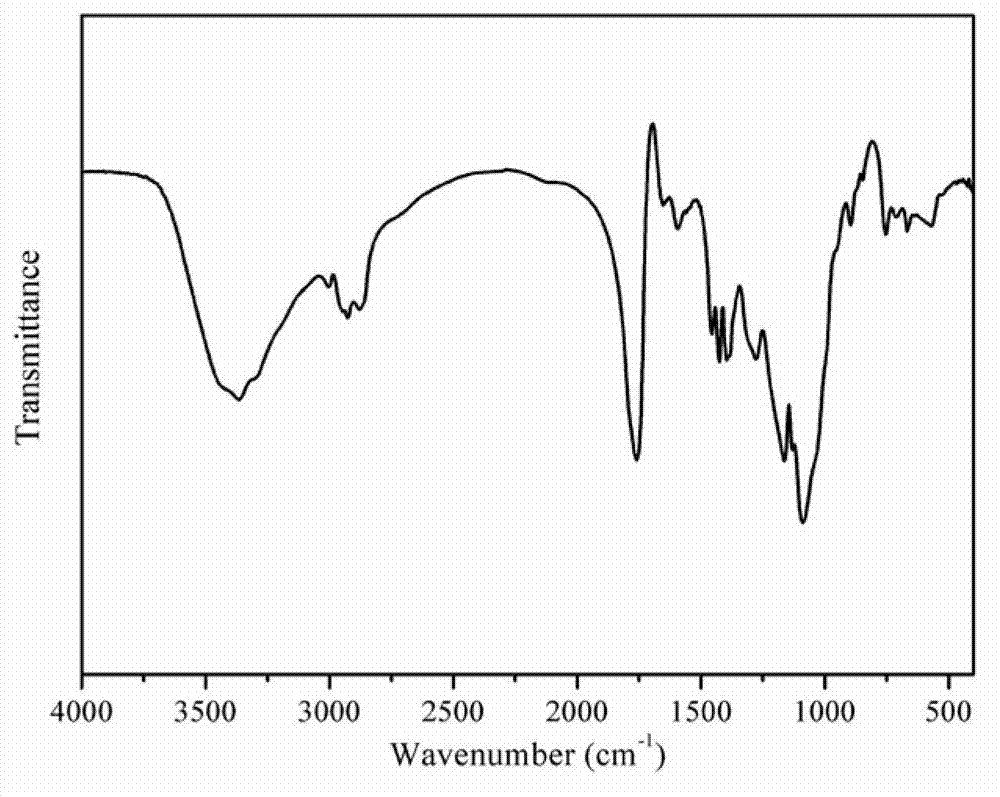

[0029] Embodiment 1: the preparation of chitosan / polylactic acid amphiphilic graft copolymer

[0030] Weigh 0.05g of molecular weight to be 1.0×10 5 , Chitosan with a degree of deacetylation of 70% and 0.04 g of 1-hydroxybenzotriazole were dissolved in 10 mL of deionized water to obtain an aqueous phase. Weigh 3.0 g of polylactic acid with a molecular weight of 10,000 kDa and dissolve it in 30 mL of dichloromethane to prepare a solution with a concentration of 100 g / L to obtain an oil phase. After the polylactic acid is completely dissolved, add 0.6g emulsifier Span 80 and 0.17g condensing agent EDC. In the state of stirring, the chitosan solution of the water phase is added dropwise into the oil phase to obtain the water-in-oil type mixed emulsion. The mixed emulsion was placed in a homogenizer for high-speed emulsification and dispersion at 10,000 rpm for 3 minutes, and then placed on a magnetic stirrer at room temperature to continue the reaction for 12 hours. After the ...

Embodiment 2

[0031] Embodiment 2: the preparation of chitosan / polylactic acid amphiphilic graft copolymer

[0032] Weigh 0.05g of molecular weight to be 1.0×10 5 1. Chitosan with a degree of deacetylation of 85% and 0.04 g of 1-hydroxybenzotriazole were dissolved in 10 mL of deionized water to obtain an aqueous phase. Weigh 3.0 g of polylactic acid with a molecular weight of 5,000 kDa and dissolve it in 30 mL of chloroform to prepare a solution with a concentration of 100 g / L to obtain an oil phase. After the polylactic acid is completely dissolved, add 0.6g emulsifier Span 80 and 0.17g condensing agent EDC. In the state of stirring, the chitosan solution of the water phase is added dropwise into the oil phase to obtain the water-in-oil type mixed emulsion. The mixed emulsion was placed in a homogenizer for high-speed emulsification and dispersion at 10,000 rpm for 5 minutes, and then placed on a magnetic stirrer at room temperature for 24 hours. After the reaction was completed, the em...

Embodiment 3

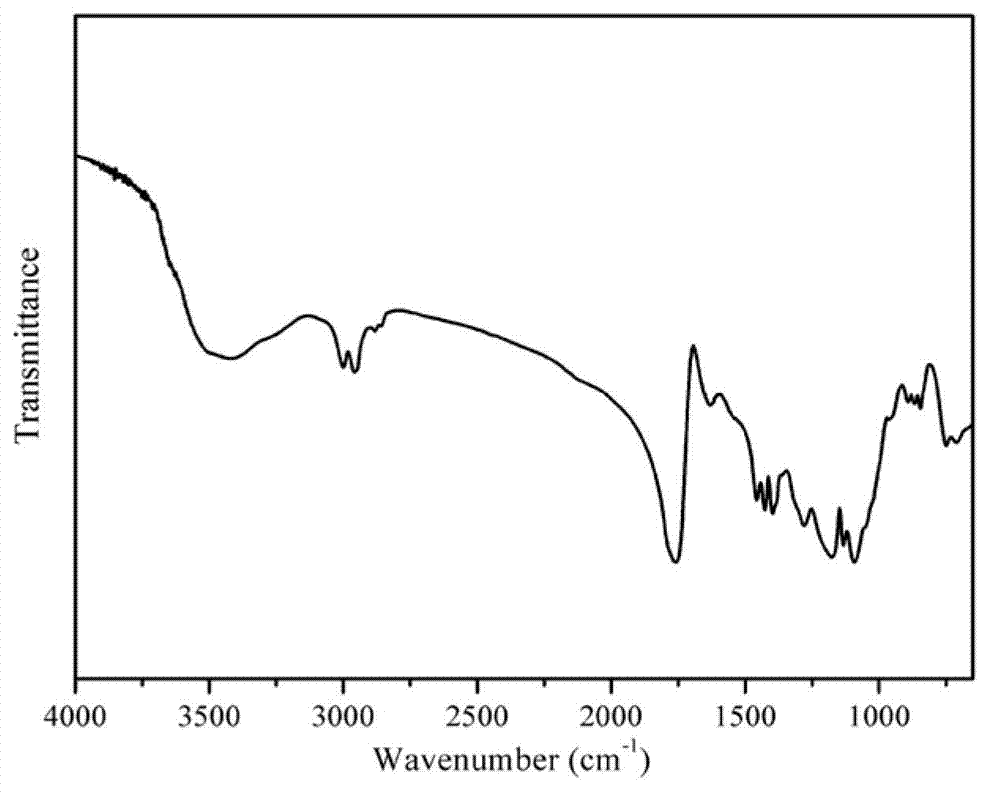

[0033]Embodiment 3: the preparation of chitosan / polyglycolic acid amphiphilic graft copolymer

[0034] Weigh 0.05g of molecular weight to be 1.0×10 5 , Chitosan with a degree of deacetylation of 70% and 0.04 g of 1-hydroxybenzotriazole were dissolved in 10 mL of deionized water to obtain an aqueous phase. Weigh 3.0 g of polyglycolic acid with a molecular weight of 10,000 kDa and dissolve it in 30 mL of dichloromethane to prepare a solution with a concentration of 100 g L to obtain an oil phase. After the polyglycolic acid is completely dissolved, add 0.6g emulsifier Span 80 and 0.17g condensing agent EDC. In the state of stirring, the chitosan solution of the water phase is added dropwise into the oil phase to obtain the water-in-oil type mixed emulsion. The mixed emulsion was placed in a homogenizer for high-speed emulsification and dispersion at 10,000 rpm for 3 minutes, and then placed on a magnetic stirrer at room temperature to continue the reaction for 12 hours. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com