Graphite and transitional metallic oxide composite cathode material and preparation method thereof

A transition metal and negative electrode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems that affect the practicality of transition metal oxides, poor conductivity of metal oxides, and severe volume changes, and achieve good electrochemical performance. The effect of low equipment investment and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 prepares iron oxide / graphite composite negative electrode material by iron oxide and graphite

[0031] The preparation method is: use a balance to weigh 0.6g of iron oxide with a particle size of about 20nm, and 2.4g of graphite with a particle size of about 20μm, and grind them evenly in a mortar to obtain an iron oxide / graphite composite negative electrode material, and an aqueous solution prepared with 0.9g of glucose After mixing 10 ml evenly, dry at 105° C., then heat to 500° C. in a nitrogen atmosphere, and keep the temperature for 5 hours to obtain a composite negative electrode material coated with carbon on the surface.

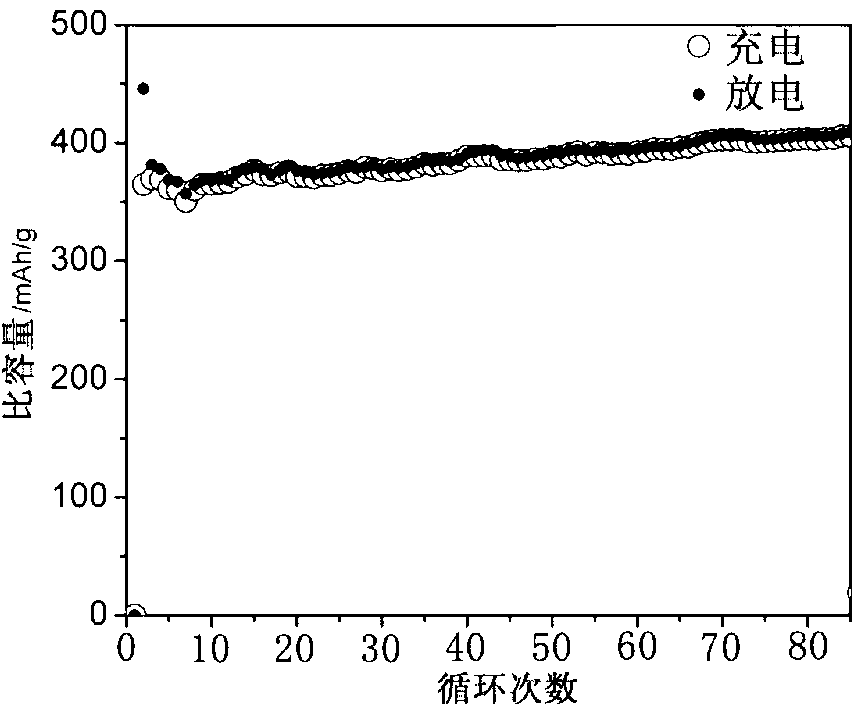

[0032] The cycle performance of the iron oxide / graphite composite negative electrode material obtained in this embodiment is as follows: figure 2 As shown, the capacity of charging and discharging 85 times was measured at 0.1C rate to be 408.7mAh / g.

Embodiment 2

[0033] Example 2 Preparation of Iron Oxide / Graphite Composite Anode Material by Iron Oxide and Graphite

[0034] The preparation method is: use a balance to weigh 0.9g of iron oxide with a particle size of about 20nm, and 2.1g of graphite with a particle size of about 20μm, and grind them evenly in a mortar to obtain an iron oxide / graphite composite negative electrode material, and an aqueous solution prepared with 0.9g of glucose After mixing 10 ml evenly, dry it at 120°C, then heat it to 550°C in a nitrogen atmosphere, and keep it warm for about 5 hours to obtain a carbon-coated composite negative electrode material.

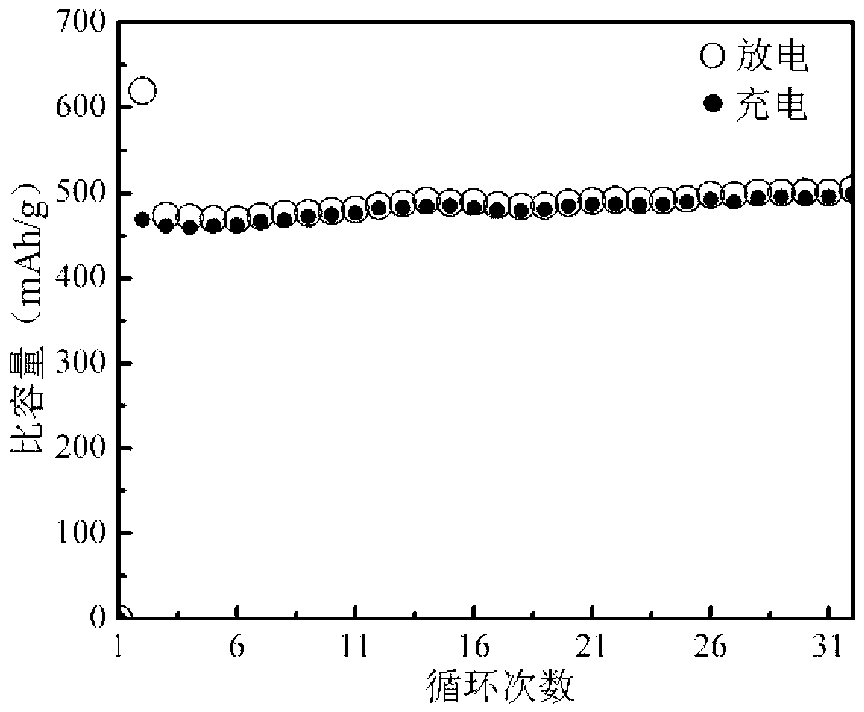

[0035] The battery assembled by the carbon-coated iron oxide / graphite composite negative electrode material obtained in this example has a cycle performance at a rate of 0.1C as follows: image 3 As shown, the capacity of charging and discharging 30 times is 497mAh / g.

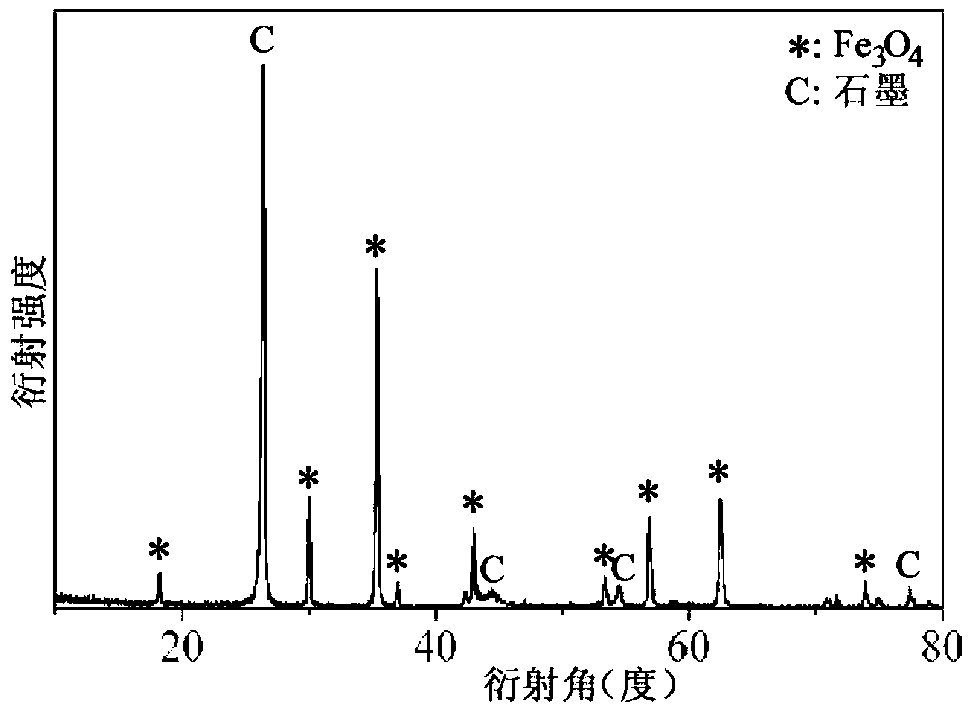

[0036] The X-ray diffraction pattern of the carbon-coated iron oxide / graphite composite ne...

Embodiment 3

[0037] Example 3 Preparation of Iron Oxide / Graphite Composite Anode Material by Iron Oxide and Graphite

[0038] The preparation method is: use a balance to weigh 1.2g of iron oxide with a particle size of about 20nm, and 1.8g of graphite with a particle size of about 6μm, and grind them evenly in a mortar to obtain an iron oxide / graphite composite negative electrode material, and an aqueous solution prepared with 0.9g of glucose After mixing 10 ml evenly, dry at 105° C., then heat to 550° C. in a nitrogen atmosphere, and keep the temperature for 5 hours to obtain a carbon-coated composite negative electrode material. The battery assembled from this carbon-coated iron oxide / graphite composite negative electrode material has a capacity of 483mAh / g measured at 0.1C rate for 30 times of charge and discharge. Each charge and discharge cycle is carried out 10 times, and the capacity can reach 481.5, 463.4, 357.7, 287.4mAh g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com