Optimized alkaline pectinase gene and application thereof

A pectinase and alkaline technology, applied in application, genetic engineering, plant genetic improvement and other directions, can solve the problems of low expression of alkaline pectinase gene, excessive residual toxic substances, consumption of large chemical substances and heat energy, etc. To achieve the effect of simplifying the downstream purification work, simple production process and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

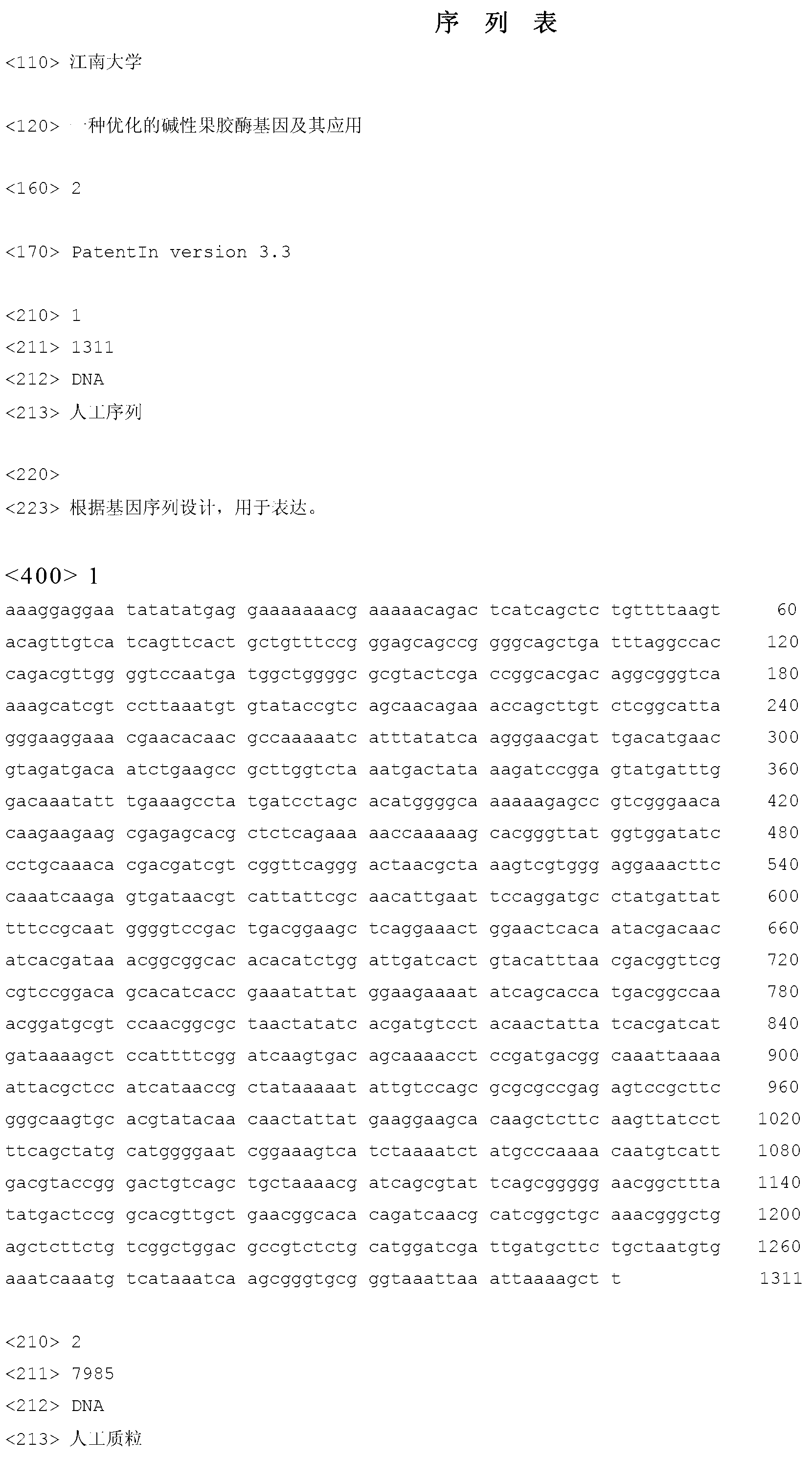

[0015] Embodiment 1: the acquisition of alkaline pectinase gene sequence

[0016] The alkaline pectinase gene (pgl) sequence was derived from Bacillus sp.WSHB04-02, and the sequence of the alkaline pectinase coding region was synthesized by chemical total synthesis.

Embodiment 2

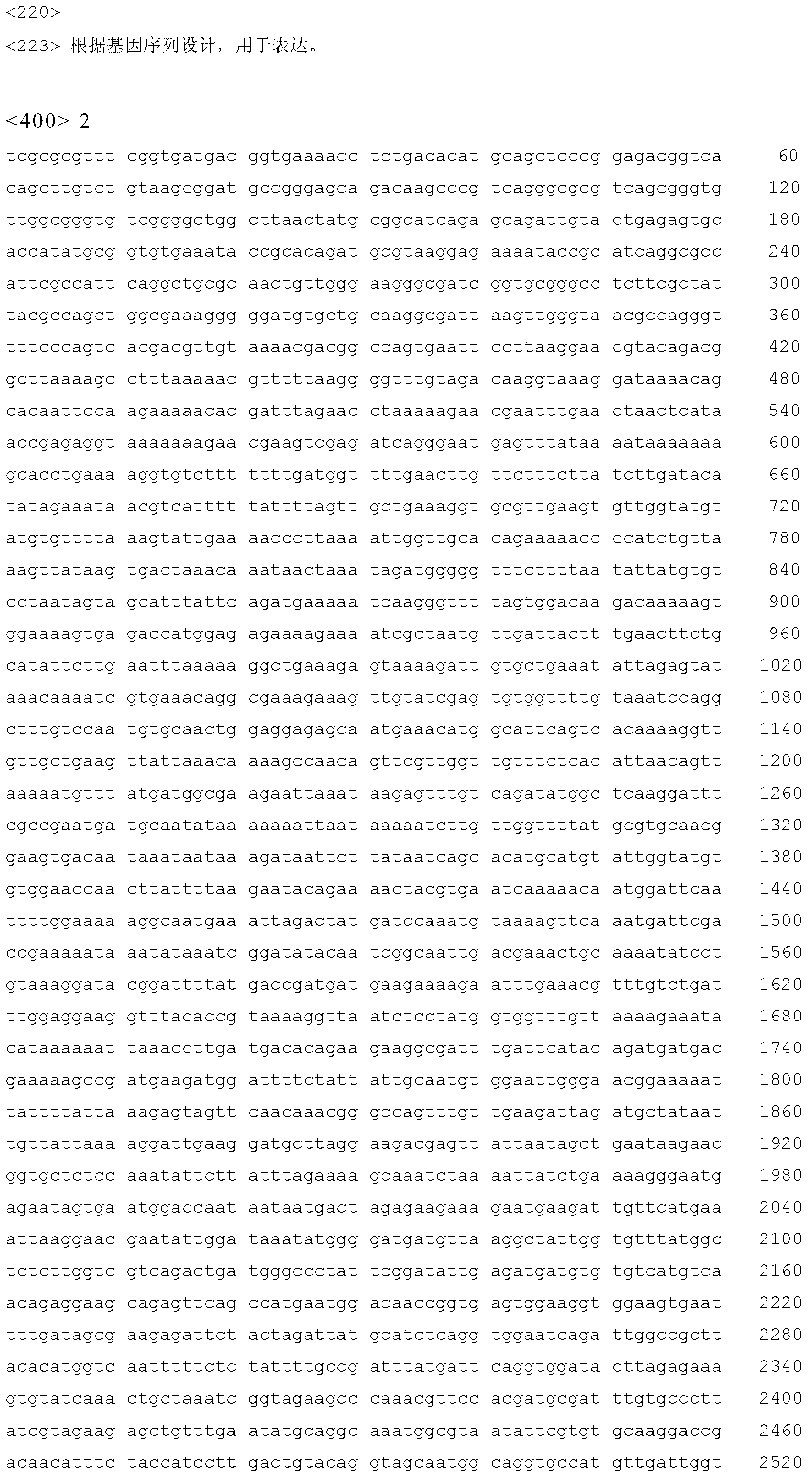

[0017] Example 2: Construction of recombinant plasmid vector pP43NMK1217

[0018] The alkaline pectinase gene obtained in Example 1 and the cloning vector pET-20 (+) were subjected to double digestion with SalI and NcoI respectively. The enzyme digestion system was as follows: 40 μL of plasmid, 5 μL of 10×buffer, 2.5 μL of SalI, 2.5 μL of NcoI . Gently mix the above components, and digest at 37°C for 20min. Then 0.8% agarose gel electrophoresis was used to verify and recover the PCR amplification products. Afterwards, the cloning vector obtained by digestion was ligated with the target gene, and the ligation reaction system (10 μL): 4 μL of the target gene pgl, 1 μL of the cloning vector pET-20b (+), 5 μL of ligase SolutionI, 16°C, ligated overnight. Then the ligation product was transformed into competent Escherichia coli JM109, and the transformation method was as follows:

[0019] (1) Take 100 μL of frozen-preserved competent cells and melt them in an ice bath;

[0020]...

Embodiment 3

[0028] Embodiment 3: the cultivation of recombinant bacterial strain

[0029] Glycerol tube: the concentration of glycerol is 20%; the composition of the seed medium is (g / L): sucrose 20, peptone 10, corn steep liquor 30, dipotassium hydrogen phosphate 18.4, potassium dihydrogen phosphate 6, pH 7.0, 50 μg / mL card Namycin; fermentation medium composition (g / L): corn starch 15, peptone 8, yeast extract 10, dipotassium hydrogen phosphate 9.2, potassium dihydrogen phosphate 3, pH 7.0, 50 μg / mL kanamycin;

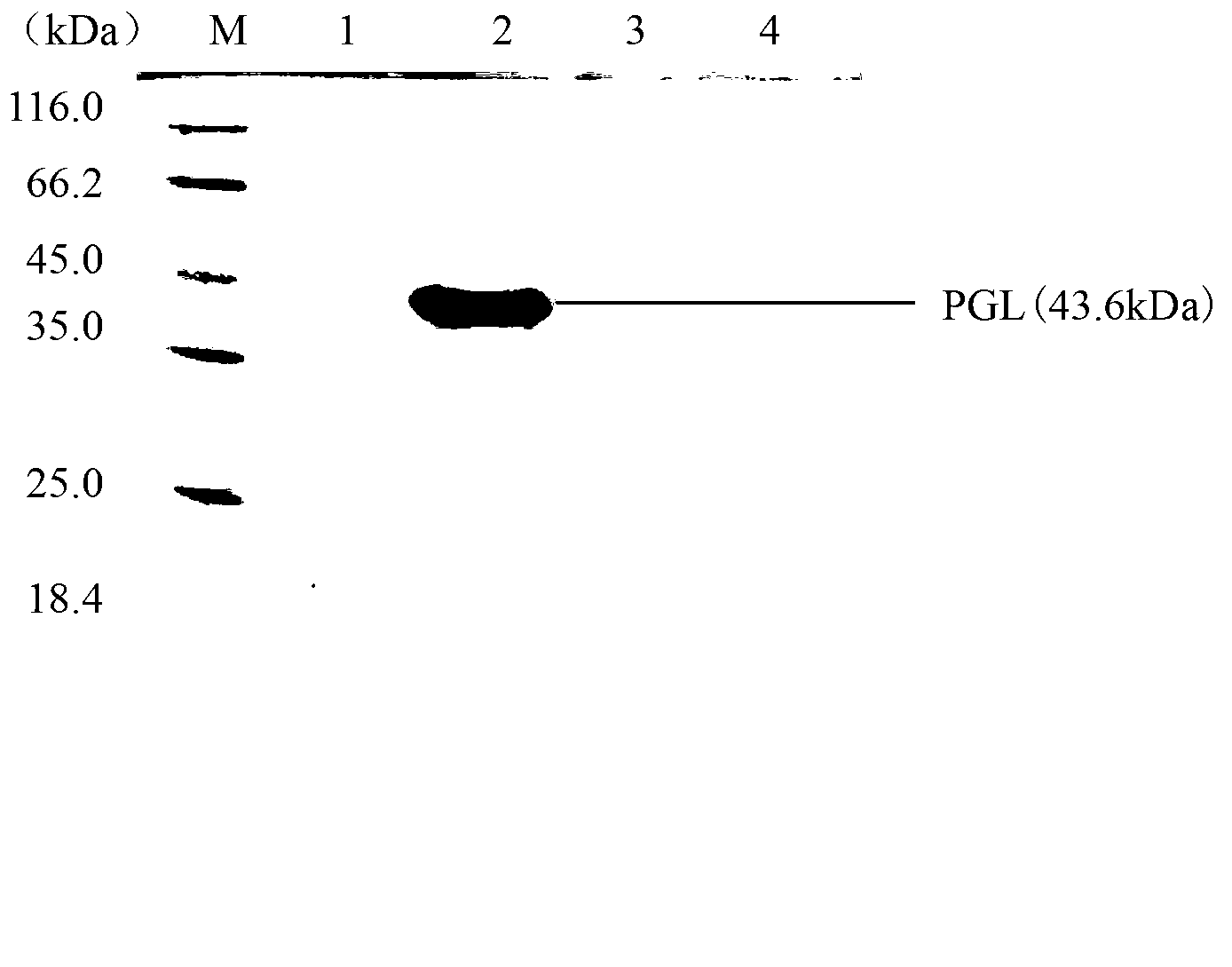

[0030] Seed culture: Inoculate 0.4% of the inoculum from the glycerol tube into a 25mL / 250mL Erlenmeyer flask, rotate the rotary shaker at 200rpm, cultivate at a temperature of 37°C, and cultivate for 14 hours; The inoculum amount of (v / v) was inoculated into a 25mL / 250mL Erlenmeyer flask for cultivation, the cultivation temperature was 37°C, the shaker speed was 200rpm, and after cultivation for 2-3 days, the production of alkaline protease could reach 460U / ml, as shown in SDS-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com