Palladium-carbon nanocatalyst and preparation method thereof

A palladium nano-catalyst technology, applied in the field of proton exchange membrane fuel cell anode electrocatalyst and its preparation, can solve the problems of low electrocatalytic activity and stability, and achieve the effects of promoting uniform deposition, optimizing structure and distribution, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

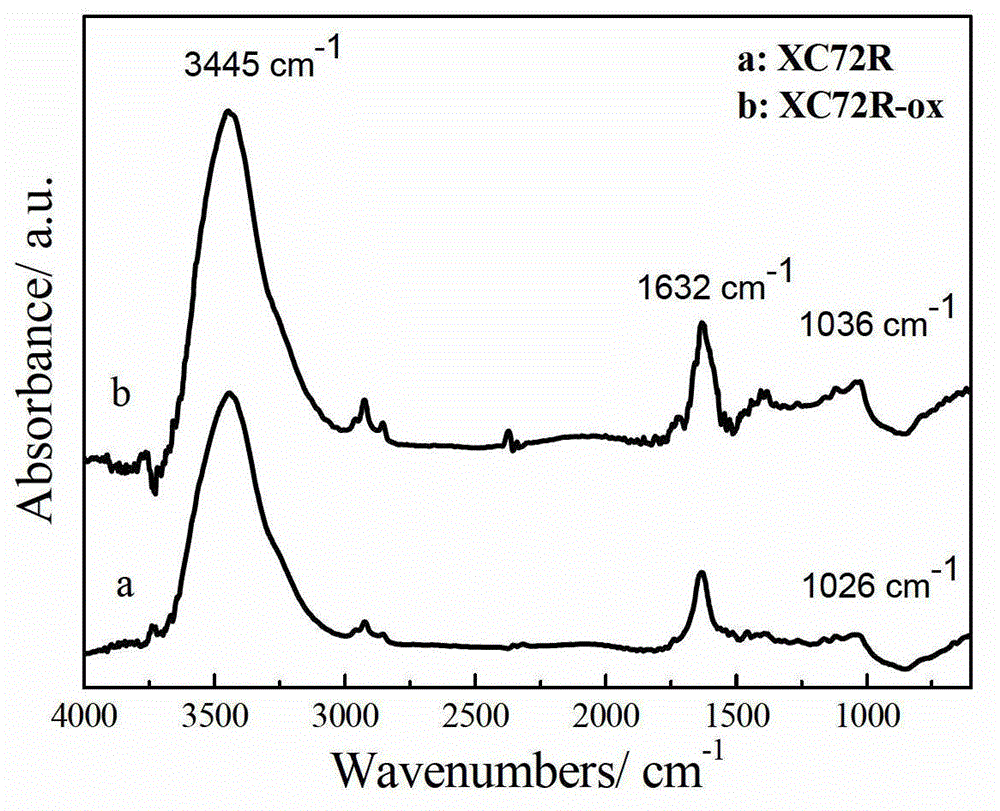

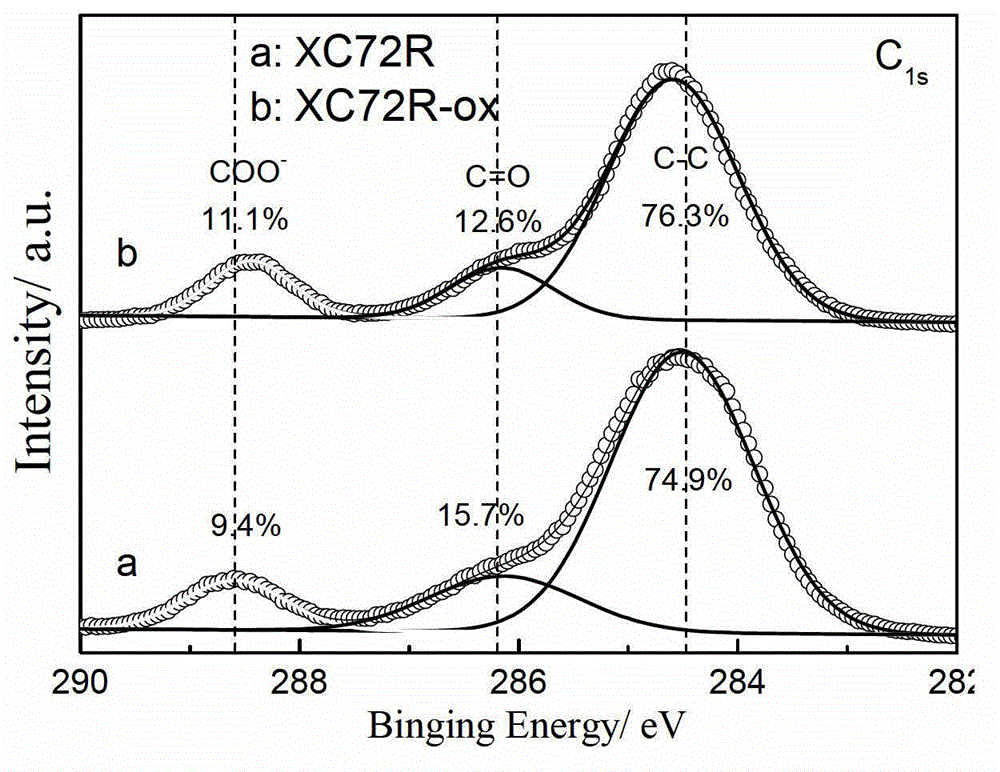

[0039] Example 1: Synthesis of modified carbon carrier by two-step oxidation method

[0040] The preparation method of the modified carbon support is a liquid-phase two-step oxidation method. The first step of oxidation is: take 0.3g of commercial carbon black XC72R, 0.5g of phosphorus pentoxide and 0.5g of potassium persulfate into a 50mL three-necked flask in turn, then slowly add 2.4mL of sulfuric acid ( 98%) into the above mixture, heated in an oil bath to 80°C, and reacted for 4.5 hours; cooled the reactant to room temperature, then slowly added 10 mL of deionized water dropwise, and then added 20 mL of deionized water after the dilution was complete; The obtained product was suction-filtered, washed repeatedly with water until the filtrate was neutral, and the filter cake was dried in a drying oven at 70°C for 12 hours. The second step of oxidation is: put the carbon carrier obtained in the first step oxidation into a three-necked flask, add 1.5g of potassium permangana...

Embodiment 2

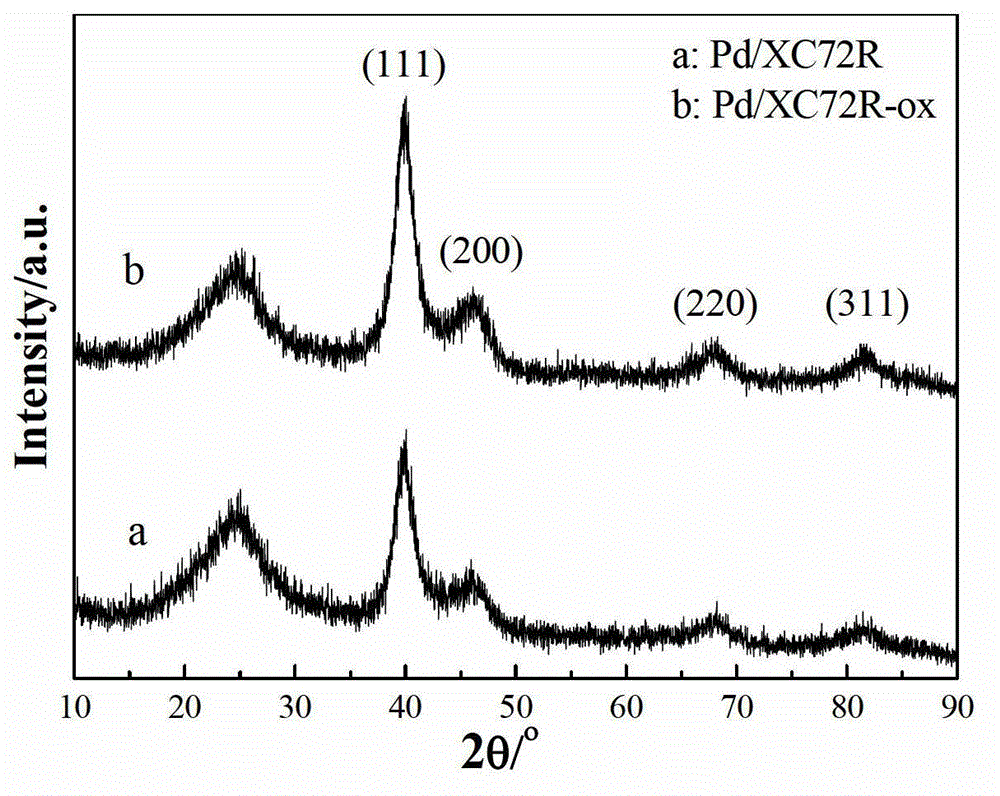

[0046] Embodiment 2: the preparation of carbon-supported palladium nano-catalyst

[0047] The preparation steps of carbon-supported palladium nano-catalyst are as follows: Weigh 37.5 mg of palladium chloride (PdCl 2 ) into a three-necked flask, add 8mL of deionized water, and then dropwise add 2.1mL of 0.1mol·L -1 EDTA disodium solution, then heated in a water bath to 60°C, and magnetically stirred for 30min to form a Pd complex. Next, 90 mg of modified carbon support (XC72R-ox) was dispersed in the aqueous solution of palladium complex, and ultrasonically dispersed for 30 min. Then 126 mg of sodium borohydride was pre-dissolved in 8 mL of deionized water, slowly added dropwise to the above mixture, and stirred for 30 min under ice bath. Then it was filtered with suction, washed with water repeatedly, checked with silver nitrate solution until there was no chloride ion in the filtrate, and the obtained solid product was vacuum-dried at 70°C for 24 hours to obtain a Pd / XC72R-...

Embodiment 3

[0048] Embodiment 3: the electrochemical performance of carbon-supported palladium nano-catalyst

[0049] The electrochemical test steps of carbon-supported palladium nano-catalysts are as follows: weigh 5-10 mg of catalyst, pipette a certain amount of deionized water and Nafion solution, prepare ink, and disperse evenly by ultrasonic. Pipette 3 μL of ink onto the surface of the pre-exposed polished glassy carbon electrode, and let it dry naturally in the air. Electrochemical tests were performed on a CHI 660D electrochemical workstation of Shanghai Chenhua Company. A three-electrode system is adopted, the reference electrode is a saturated calomel electrode, the counter electrode is a platinum sheet electrode, and the working electrode is a glassy carbon electrode. The electrolyte is 0.5mol L -1 sulfuric acid solution or 0.5mol L -1 Sulfuric acid and 0.5mol·L -1 A mixed solution of formic acid. Before the test, pass high-purity nitrogen gas into the electrolyte for 15-20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com