Antibacterial and antireflection glass plating solution composition, making method thereof and purpose thereof

An anti-reflection glass and composition technology, which is applied in the field of antibacterial anti-reflection glass plating solution composition, achieves the effects of simple preparation, excellent anti-reflection effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

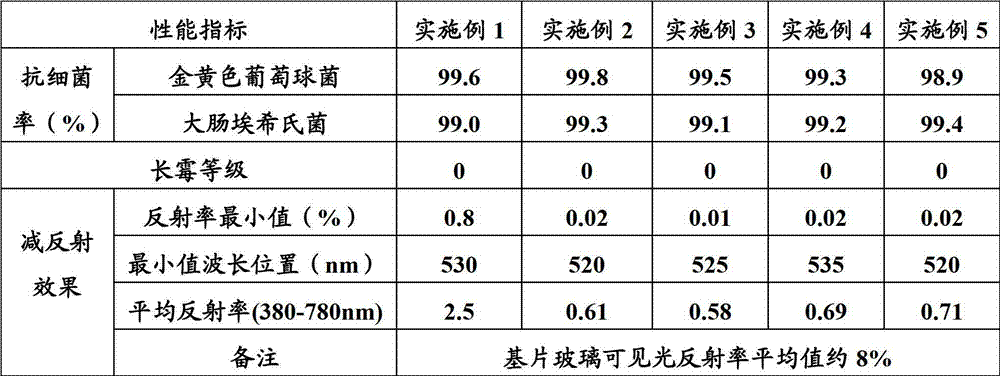

Examples

Embodiment 1

[0050] Mix 20 grams of isopropyl titanate, 2 grams of acetic acid, and 25 grams of isopropanol to form dispersion system A; mix 10 grams of silver nitrate, 8 grams of acetonitrile, and 20 grams of isopropanol to form dispersion system B; Mix 10 grams of isopropanol, 3 grams of water, and 2 grams of diethylamine uniformly to form dispersion system C; after combining dispersion system A and dispersion system B, slowly add dispersion system C to it, mix uniformly to form a high refractive index sol-gel Rubber base.

[0051] Mix 31 grams of methyl orthosilicate, 3 grams of hydrochloric acid, and 26 grams of isopropanol to form dispersion system D; mix 8 grams of silver nitrate, 10 grams of isopropanol, and 6 grams of diethylene glycol ether to form dispersion system D. System E; Mix 2 grams of ammonia water, 10 grams of isopropanol, and 4 grams of water to form dispersion system F; after combining dispersion system D and dispersion system E, slowly add dispersion system F to it an...

Embodiment 2

[0054] Mix 20 grams of isopropyl titanate, 2 grams of acetic acid, and 25 grams of isopropanol to form dispersion system A; mix 10 grams of silver nitrate, 8 grams of acetonitrile, and 20 grams of isopropanol to form dispersion system B; Mix 10 grams of isopropanol, 3 grams of water, and 2 grams of diethylamine uniformly to form dispersion system C; after combining dispersion system A and dispersion system B, slowly add dispersion system C to it, mix uniformly to form a high refractive index sol-gel Rubber base.

[0055] Mix 28 grams of methyl orthosilicate, 3 grams of hydrochloric acid, and 26 grams of isopropanol to form a dispersion system D; mix 8 grams of silver nitrate, 10 grams of isopropanol, and 6 grams of diethylene glycol ether to form a dispersion System E; mix 2 grams of ammonia water, 10 grams of isopropanol, and 4 grams of water to form dispersion system F; after combining dispersion system D and dispersion system E, slowly add dispersion system F to it, and fin...

Embodiment 3

[0058] Mix 18 grams of titanium tetrachloride, 2 grams of nitric acid, and 23 grams of isopropanol / methanol mixed solvent (the volume ratio of isopropanol to methanol is 2:1) to form dispersion system A; mix 5 grams of silver nitrate and 7 grams of Zinc chloride, 6 grams of acetonitrile and 5 grams of thiourea, 20 grams of isopropanol / methanol mixed solvent (the volume ratio of isopropanol and methanol is 2:1) are mixed uniformly to form dispersion system B; 8 grams of isopropanol / methanol Methanol mixed solvent (the volume ratio of isopropanol to methanol is 2:1), 3 grams of water, and 3 grams of diethanolamine are mixed evenly to form dispersion system C; after combining dispersion system A and dispersion system B, slowly add dispersion System C, forming a high refractive index sol-gel primer.

[0059] Mix 30 grams of tetraethyl orthosilicate, 2 grams of hydrochloric acid, and 25 grams of isopropanol / methanol mixed solvent (the volume ratio of isopropanol to methanol is 2:1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com