Preparation method of carbasalate calcium

A technology of carbasalate calcium and aspirin, which is applied in the field of veterinary drug preparation, can solve problems such as poor product quality controllability, high production cost, and insufficient reaction, and achieve the effects of facilitating industrial production, reducing equipment requirements, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of carbasalate calcium, the steps are as follows:

[0031] (1) Add 100g of aspirin, 46g of calcium nitrate and 20g of urea in sequence to 300ml of methanol, and stir at room temperature for 30min; then cool down, and add 35mL of ammonia water at a rate of 1-2ml per minute at 0-2°C while stirring, Then the temperature was raised to 32-35°C and reacted for 2 hours to obtain the reaction solution;

[0032] (2) Cool the reaction solution prepared in step (1) to 2-4°C, grow the crystal for 1 hour, then filter it with suction, and dry it in vacuum at 45-50°C for 3.5 hours to obtain 118 g of carbasalate calcium. The rate is 93%.

[0033] The test results of sample content and related substances are shown in Table 1, and the test results of sample stability are shown in Table 2.

Embodiment 2

[0035] A preparation method of carbasalate calcium, the steps are as follows:

[0036] (1) Add 100g of aspirin, 46g of calcium nitrate, and 20g of urea to 250mL of ethanol in sequence, stir and dissolve at room temperature for 30min; then cool down, and add 34mL of ammonia water at a rate of 1-2ml per minute at 2-4°C while stirring , and then heated up to 30-33°C, and reacted for 2 hours to obtain a reaction solution;

[0037] (2) Cool the reaction solution prepared in step (1) to 3-5°C, grow the crystal for 1 hour, then filter it with suction, and dry it in vacuum at 45-50°C for 4 hours to prepare 120 g of carbasalate calcium. The rate is 95%.

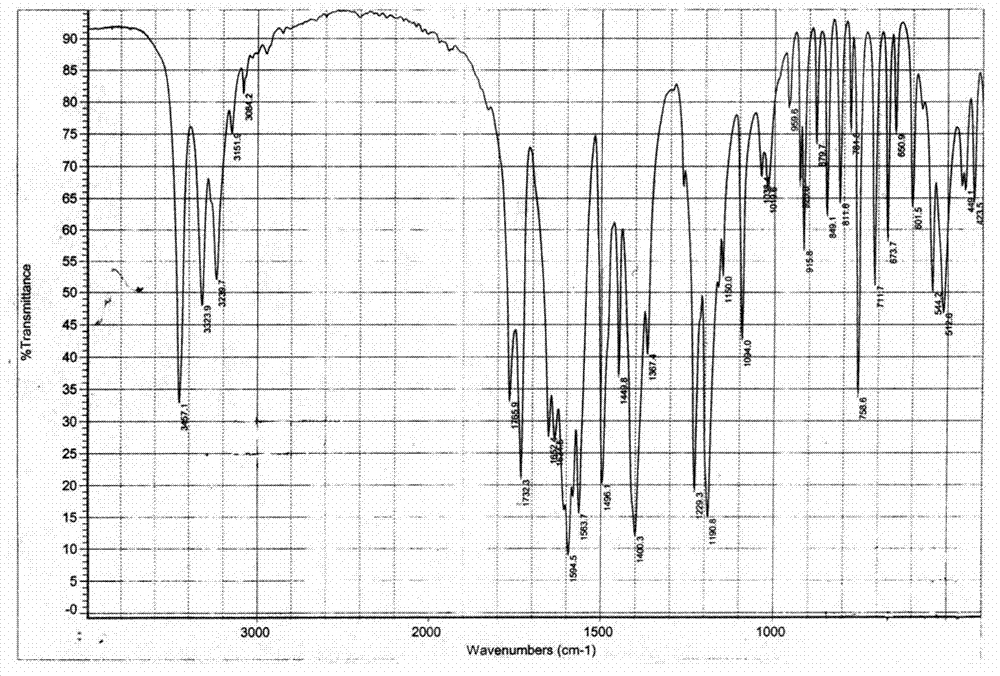

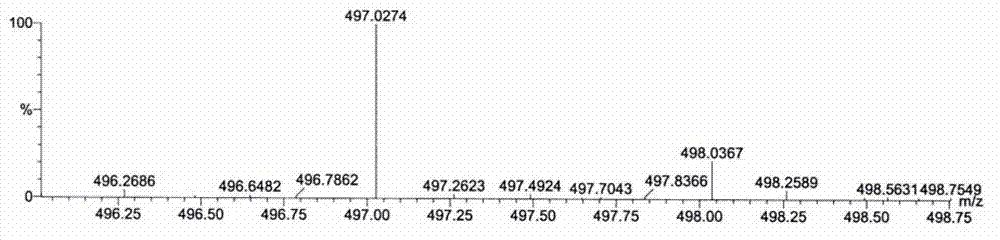

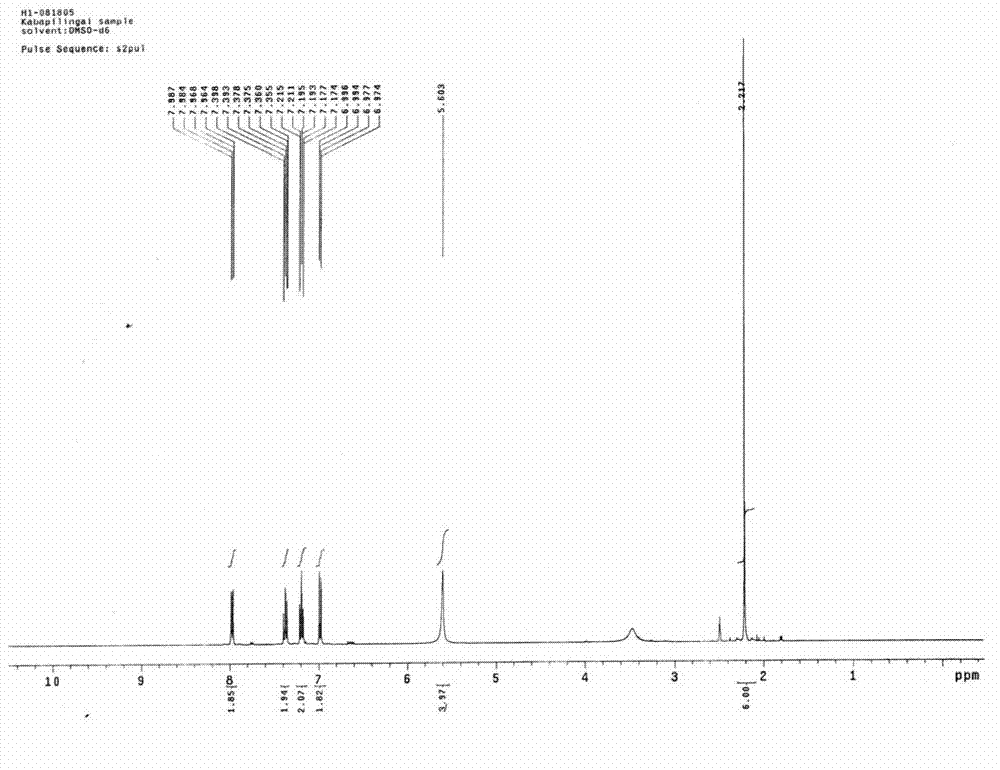

[0038] The obtained carbasalate calcium was confirmed by infrared spectrum, mass spectrum and nuclear magnetic resonance structure, and the results were as follows: Figure 1~3 shown.

[0039] The test results of sample content and related substances are shown in Table 1, and the test results of sample stability are shown in Table ...

Embodiment 3

[0041] A preparation method of carbasalate calcium, the steps are as follows:

[0042] (1) Add 100g of aspirin, 46g of calcium nitrate, and 20g of urea to 200mL of ethanol in sequence, stir and disperse at room temperature for 30min; then cool down, add 38mL of ammonia water at a rate of 1-2ml per minute under stirring at 3-5°C , and then heated up to 25-28°C, and reacted for 2 hours to obtain a reaction solution;

[0043] (2) Cool the reaction solution prepared in step (1) to 0-2°C, grow the crystal for 1 hour, then filter it with suction, and dry it in vacuum at 45-50°C for 3 hours to obtain 118 g of carbasalate calcium, which was harvested The rate is 93%.

[0044] The test results of sample content and related substances are shown in Table 1, and the test results of sample stability are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com