Ternary electric memory material of azo chromophore of imide framework, as well as preparation and application of ternary electric memory material

An imide and skeleton technology, applied in the field of azo molecular ternary electrical storage materials, can solve the problems of unclear storage mechanism and lack of functional materials, and achieve mature device fabrication process, great value, and stable device performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of a novel azo molecular ternary electrical storage material based on imide skeleton of general formula I

[0044]

[0045] Where Ar is R is N, N-two C 1 ~C 6 Alkylphenyl, N,N-diphenylaminophenyl or p-hydroxyphenyl.

[0046] When Ar is When R is N,N-dimethylphenyl, the synthesis steps are as follows:

[0047] (1) Dissolve 4-nitroaniline (2.76g, 20.0mmol) in deionized water (8mL) and concentrated hydrochloric acid solution (8mL), heat to dissolve in a water bath, and slowly add sodium nitrite dropwise after cooling in ice water (1.38g, 20.0mmol) water (8mL) solution, the system gradually becomes homogeneous, after stirring for 1h, add cold N,N-dimethylaniline (2.42g, 20.0mmol) within 30min at 0~5℃ ) Mixed solution of concentrated hydrochloric acid (4mL) and water (20mL), stirred in an ice water bath for 2h, neutralized with 1M KOH solution, allowed to stand for a while, filtered with suction, and washed with deionized water several times.

[0048] The ob...

Embodiment 2

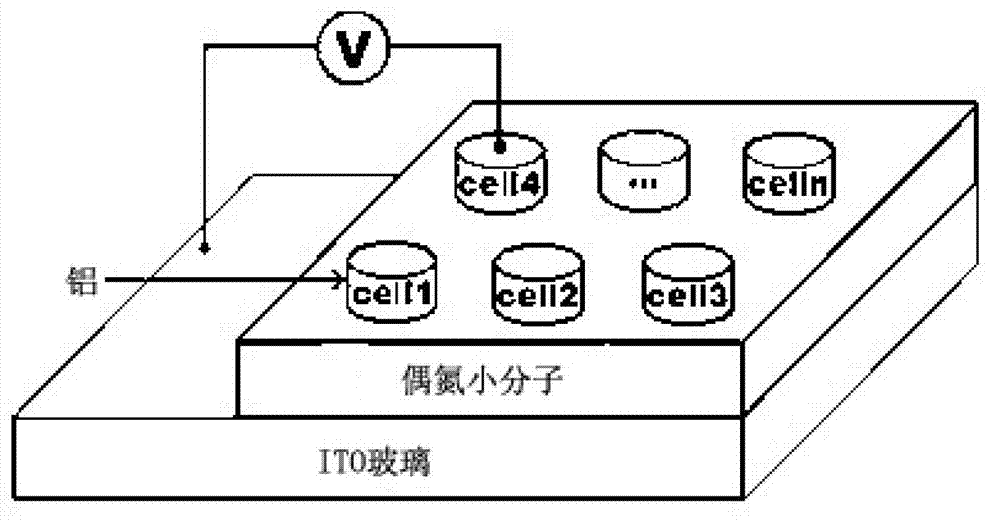

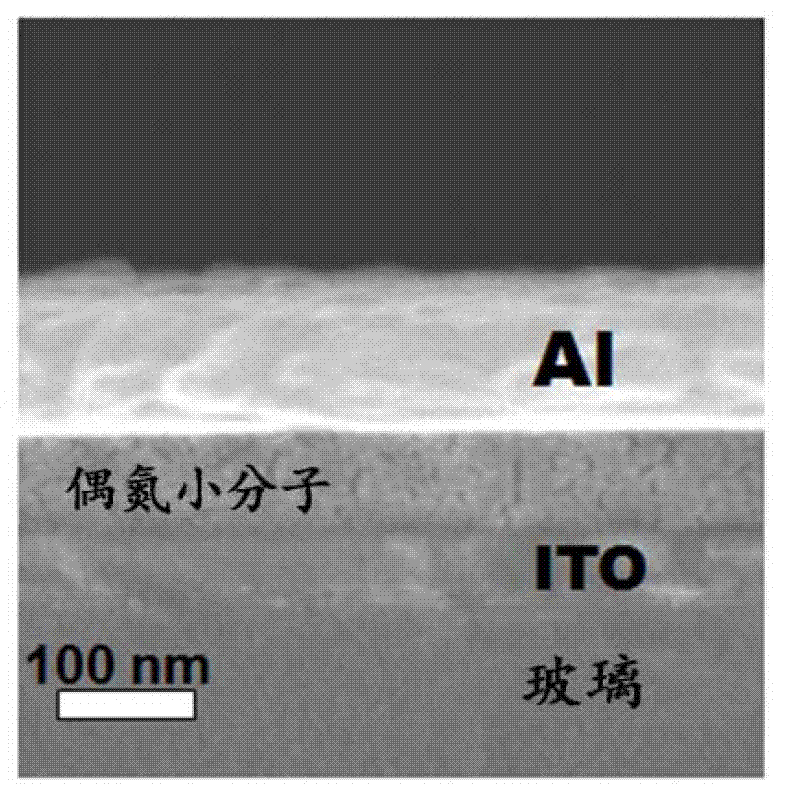

[0180] Taking the compound A1 obtained in Example 1 as an electrical storage active material as an example, an electrical storage device with a sandwich structure is prepared. The manufacturing process is as follows: ITO conductive glass is washed with water, acetone, and isopropanol in ultrasonic waves for 10-30 minutes, respectively. Placed in a vacuum coating machine as an organic material deposition substrate; take 10-30 mg of compound A1 in a quartz crucible and place it in the molybdenum boat of the vacuum coating machine, and vacuum until the pressure in the coating machine is less than 3×10 -3 Pa began to vaporize organic molecules, and the thickness of the organic film was controlled by a film thickness detector to be between 20 and 150 nm; after the organic film was vapor-deposited, carefully cover a metal mask with several round holes with a diameter of 0.2 mm on the film. A certain amount of aluminum wire is suspended on the tungsten wire of the vacuum coating machine...

Embodiment 3

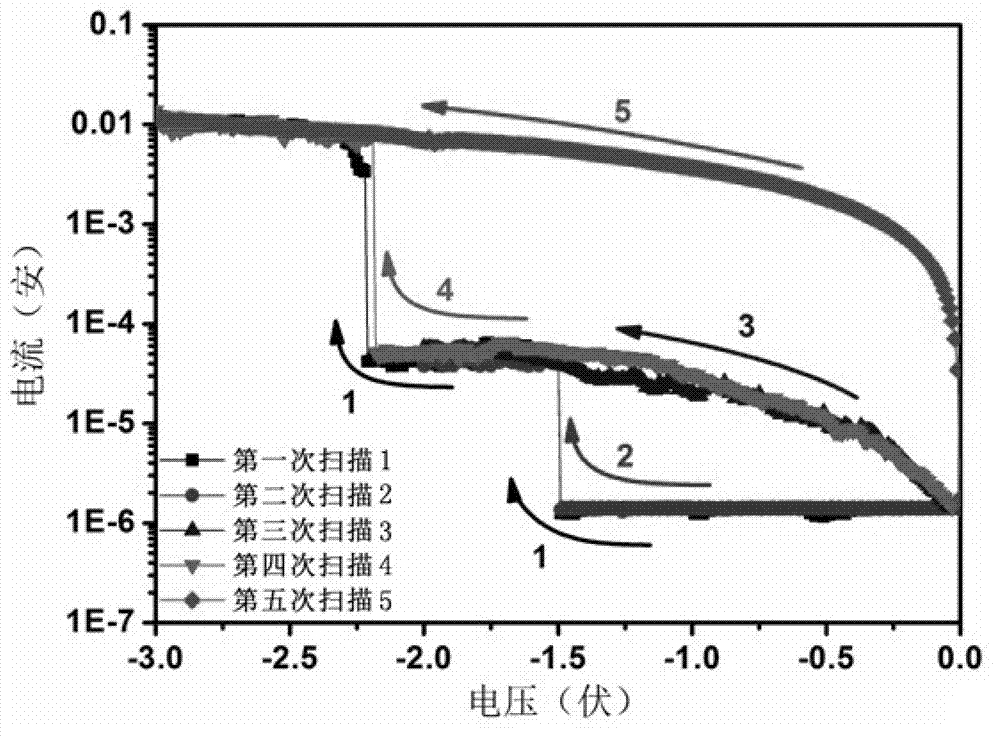

[0182] image 3 It shows the current flowing through the device when a continuous voltage is applied between the upper and lower electrodes of the memory device prepared in Example 2 for scanning. When a continuous voltage of 0 to –3V is applied to a point on the device, the current through the device is There are two instantaneous jumps between –1.50V and –2.18V, indicating that the device has gone from a low conductivity state ("0" or OFF state) to an intermediate conductivity state ("1" or ON1 state) and then to a high conductivity state ("2" or ON2 state) transition (first scan). In the subsequent scan from 0 to -3V, the memory cell still maintains its highly conductive state (second scan). The third scan is to scan another memory cell from 0 to -2.0V, with a threshold voltage of -1.50V. In the subsequent 0 to -2.0V scan, the unit can maintain the intermediate conduction state ("1") even if the power is turned off (the fourth scan). Therefore, the device has typical non-v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com