Method and device for preparing sodium carbonate by recycling tail gas of coal-fired boiler

A technology for a coal-fired boiler and a waste heat recovery device, which is applied in separation methods, chemical instruments and methods, fuels, etc., can solve the problem of not being able to fundamentally solve the problem of environmental pollution caused by a large amount of carbon dioxide emissions, and improve the utilization rate of raw materials and combustion efficiency. , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

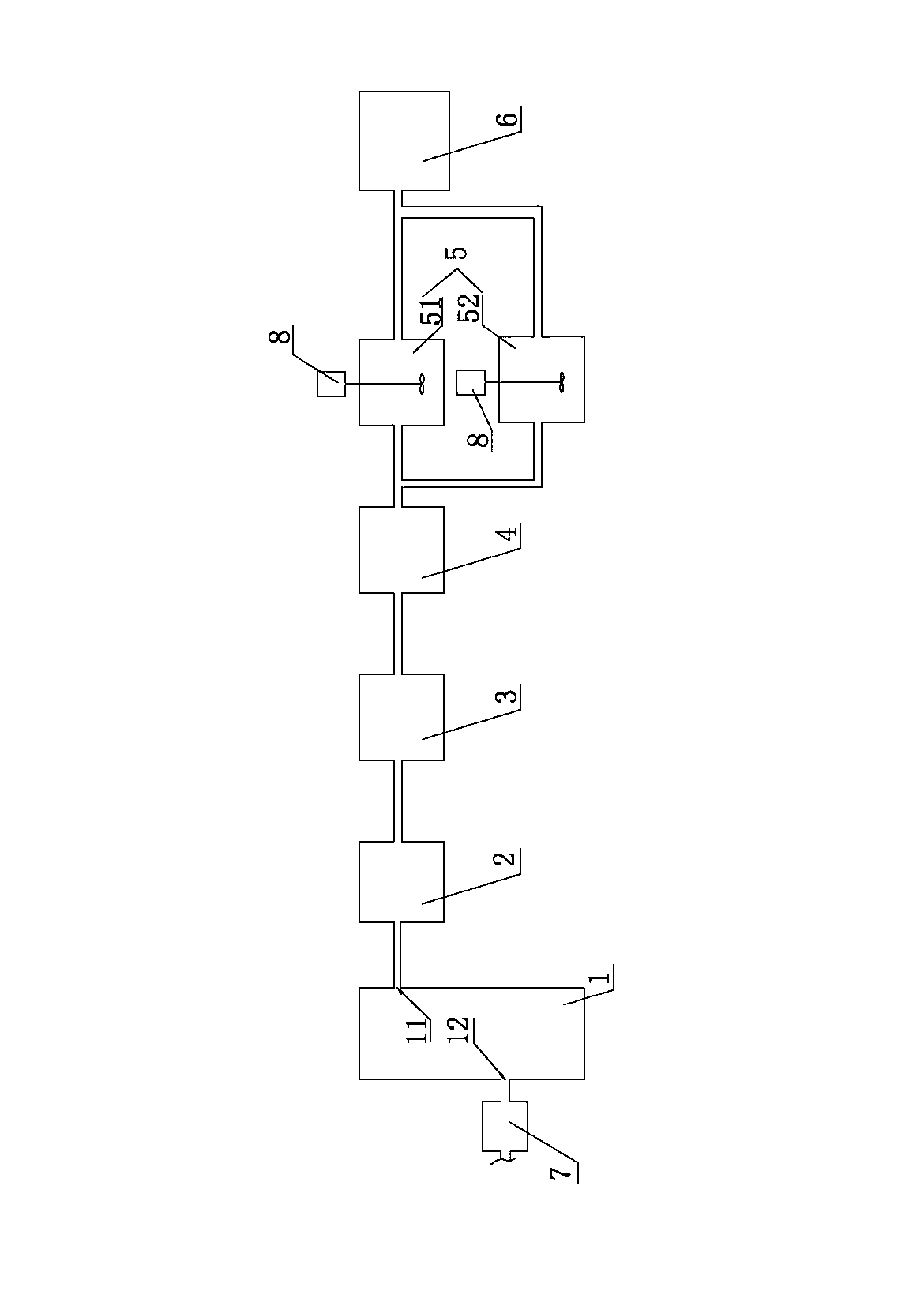

[0057] Such as figure 1 Shown, the method for the recovery and utilization of coal-fired boiler tail gas of the present invention to prepare soda ash may further comprise the steps:

[0058] Step (1): Pulverize the coal used in the coal-fired boiler 1 and add a desulfurizer to obtain desulfurized coal and put it into the boiler 1 for combustion; treat the coal before combustion so that the sulfur-containing substances after combustion in the boiler 1 remain In the ash, the content of sulfur dioxide in the tail gas discharged from the boiler 1 can be effectively reduced, and the pollution to the environment can be reduced.

[0059] Further, the air inlet 12 of the boiler 1 is provided with a membrane filter device 7, the membrane filter device 7 is an oxygen-enriched membrane filter device 7, and the membrane separation layer of the oxygen-enriched membrane filter device 7 can allow oxygen to pass through and prevent Nitrogen passes through, so the concentration of oxygen ent...

Embodiment 2

[0072] The method for preparing soda ash by recovering and utilizing tail gas of coal-fired boiler 1 of the present invention comprises the following steps:

[0073] Step (1): Pulverize the coal used in the coal-fired boiler 1 and add a desulfurizer to obtain desulfurized coal and put it into the boiler 1 for combustion; treat the coal before combustion so that the sulfur-containing substances after combustion in the boiler 1 remain In the ash, the content of sulfur dioxide in the tail gas discharged from the boiler 1 can be effectively reduced, and the pollution to the environment can be reduced.

[0074] Further, the air inlet of the boiler 1 is provided with a membrane filter device 7, the membrane filter device 7 is an oxygen-enriched membrane filter device 7, and the membrane separation layer of the oxygen-enriched membrane filter device 7 can allow oxygen to pass through and prevent nitrogen Therefore, it is possible to increase the concentration of oxygen entering the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com