Method for preparing magnetic 4A molecular sieve by using kaolin

A technology of kaolin and molecular sieve, which is applied in the field of preparing magnetic 4A molecular sieve, can solve the problem of difficult separation of fine powder zeolite products, and achieve the effects of magnetic stability, low price and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

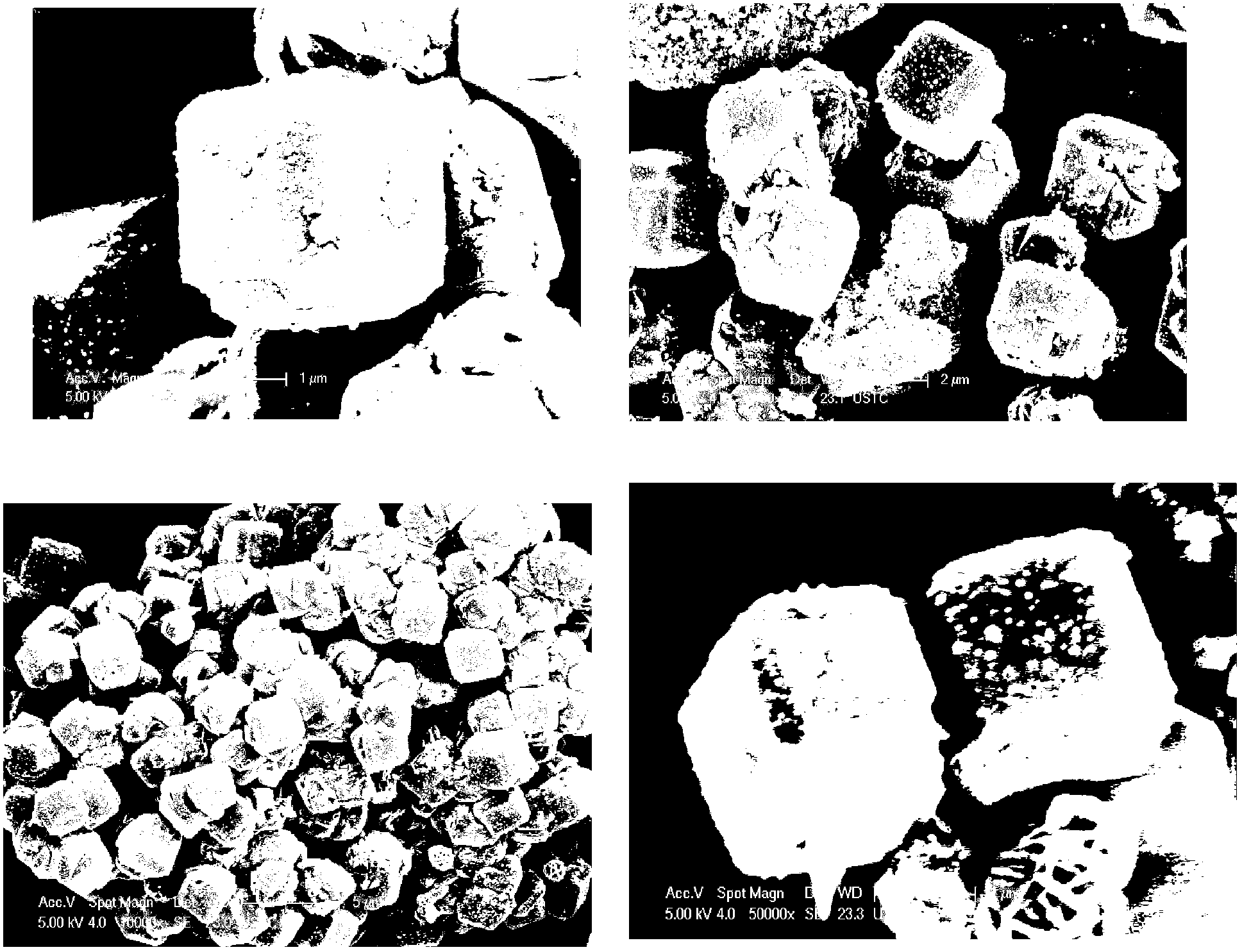

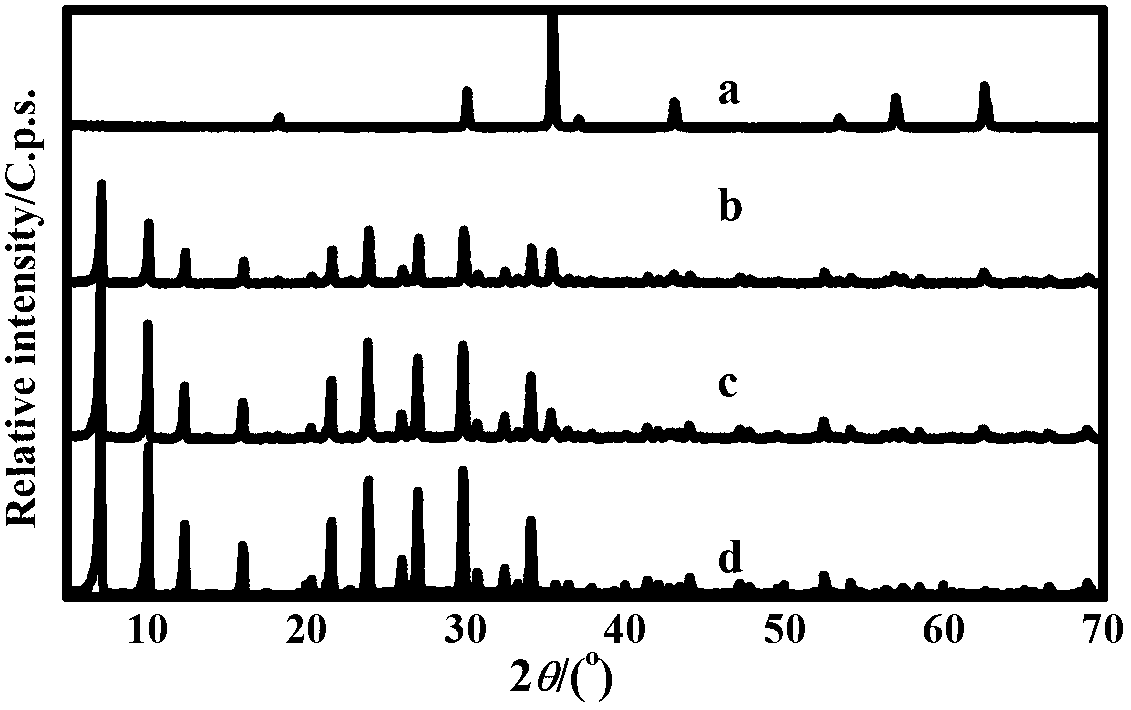

Image

Examples

Embodiment 1

[0023] 1. Pretreatment

[0024] The kaolin is crushed and ground and then magnetically separated, and the magnetically separated kaolin is passed through a 200-mesh sieve to obtain powder.

[0025] 2. Preparation of magnetic carrier

[0026] FeCl 2 and FeCl 3 Mix at a molar ratio of 1:2 and prepare a mixed solution with a total iron concentration of 0.5mol / L with deionized water. After stirring evenly, adjust the pH value to 10 with ammonia water with a mass concentration of 25%, and stir and react at 65°C for 2 hours. Then heat up to 90°C and let it stand for crystallization for 4 hours, and use a magnet to move the Fe 3 o 4 The crystals were separated and collected, washed with deionized water until neutral, and dried to obtain a magnetic carrier; the Fe 3 o 4 Prepare the magnetic fluid with deionized water, so that the magnetic carrier can be integrated into it during the molecular sieve synthesis process;

[0027] 3. Alkali-soluble roasting

[0028] Add sodium hydr...

Embodiment 2

[0036] 1. Pretreatment

[0037] The kaolin is crushed and ground and then magnetically separated, and the magnetically separated kaolin is passed through a 200-mesh sieve to obtain powder.

[0038] 2. Preparation of magnetic carrier

[0039] FeCl 2 and FeCl3 Mix at a molar ratio of 1:2 and prepare a mixed solution with a total iron concentration of 0.5mol / L with deionized water. After stirring evenly, adjust the pH value to 10 with ammonia water with a mass concentration of 25%, and stir and react at 65°C for 2 hours. Then heat up to 90°C and let it stand for crystallization for 4 hours, and use a magnet to move the Fe 3 o 4 The crystals were separated and collected, washed with deionized water until neutral, and dried to obtain a magnetic carrier; the Fe 3 o 4 Prepare the magnetic fluid with deionized water, so that the magnetic carrier can be integrated into it during the molecular sieve synthesis process;

[0040] 3. Alkali-soluble roasting

[0041] Add sodium hydrox...

Embodiment 3

[0049] 1. Pretreatment

[0050] The kaolin is crushed and ground and then magnetically separated, and the magnetically separated kaolin is passed through a 200-mesh sieve to obtain powder.

[0051] 2. Preparation of magnetic carrier

[0052] FeCl 2 and FeCl 3 Mix at a molar ratio of 1:2 and prepare a mixed solution with a total iron concentration of 0.5mol / L with deionized water. After stirring evenly, adjust the pH value to 10 with ammonia water with a mass concentration of 25%, and stir and react at 65°C for 2 hours. Then heat up to 90°C and let it stand for crystallization for 4 hours, and use a magnet to move the Fe 3 o 4 The crystals were separated and collected, washed with deionized water until neutral, and dried to obtain a magnetic carrier; the Fe 3 o 4 Prepare the magnetic fluid with deionized water, so that the magnetic carrier can be integrated into it during the molecular sieve synthesis process;

[0053] 3. Alkali-soluble roasting

[0054] Add sodium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com